Abstract

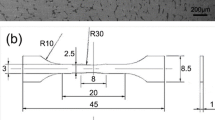

Duplex stainless steels are generally selected for applications where resistance to corrosion is the most important criteria. Several duplex stainless steel alloys are suceptible to environmental-assisted cracking and that is the subject of this invesitgation for hot-rolled alloy 2205. Duplex stainless steels (DSSs) are generally selected due to their corrosion resistance, but several environment-assisted cracking (EACs) are related to this material. Slow strain rate tests are used to evaluate the resistance to EAC, including hydrogen embrittlement and sulfide stress corrosion cracking (SSCC). In this work, a hot-rolled DSS was tested by slow strain rate tensile testing (SSRT) in two saline solutions containing H2S (10 kPa (0.1 bar) of partial pressure). Two pH levels (3.5 and 4.5) were adjusted with HCl and NaOH additions. The material was brittle in both pH levels, although the density of secondary cracks at pH 4.5 was slightly lower than at pH 3.5. This work was dedicated to analyzing the fracture surface and the secondary cracks developed in the SSRT. Lines of localized deformation of ferrite and austenite were found in the specimen tested with pH 4.5. The results were compared to the behavior of previous SSRT results and SCC failures of DSS harsh conditions.

Similar content being viewed by others

References

ASTM, A789/A789M Standard specification for seamless and welded ferritic/austenitic stainless steel tubing for general service, (2022)

R.N. Gunn, Duplex stainless steels: microstructure, properties and applications, 1st ed., Woodhead Publishing, (1997)

S. Cazottes, V. Massardier, R. Danoix, D. Rolland, S. Cissé, F. Danoix, Effect of cold rolling on phase separation in 2202 lean duplex stainless steel. Materialia. 14, 100854 (2020)

O.E. Falodun, E.B. Mtsweni, S.R. Oke, P.A. Olubambi, Influence of solution heat treatment on microstructure and mechanical properties of a hot-rolled 2205 duplex stainless steel. J. Mater. Eng. Perform. 30(10), 7185–7194 (2021)

G.N. Nigon, O. Burkan Isgor, S. Pasebani, The effect of annealing on the selective laser melting of 2205 duplex stainless steel: microstructure, grain orientation, and manufacturing challenges. Opt. Laser Technol. 134, 106643 (2021)

A.A. El-Yazgi, D. Hardie, The embrittlement of a duplex stainless steel by hydrogen in a variety of environments. Corros. Sci. 38(5), 735–744 (1996)

A.A. EL-Yazgi, D. Hardie, Stress corrosion cracking of duplex and super duplex stainless steels in sour environments. Corros. Sci. 40(6), 909–930 (1998)

NACE, NACE ISO 15156-3 Petroleum and natural gas industries - materials for use in H2S-containing environments in oil and gas production. Part 3: Cracking-resistant CRAs (corrosion- resistant alloys) and other alloys, (2015)

T. Zakroczymski, A. Glowacka, W. Swiatnicki, Effect of hydrogen concentration on the embrittlement of a duplex stainless steel. Corros. Sci. 47(6), 1403–1414 (2005)

P. Vánová, J. Sojka, Hydrogen embrittlement of duplex steel tested using slow strain rate test. Metalurgija. 53, 163–166 (2014)

S. Tsujikawa, A. Miyasaka, M. Ueda, S. Ando, T. Shibata, T. Haruna, M. Katahira, Y. Yamane, T. Aoki, T. Yamada, Alternative for evaluating sour gas resistance of low-alloy steels and corrosion-resistant alloys. Corrosion. 49(5), 409–419 (1993)

A.A. El-Yazgi, D. Hardie, Effect of heat treatment on susceptibility of duplex stainless steel to embrittlement by hydrogen. Mater. Sci. Technol. 16(5), 506–510 (2000)

ASTM, E562 - Standard test method for determining volume fraction by systematic manual point count, (2020)

ASTM, G129 Practice for slow strain rate testing to evaluate the susceptibility of metallic materials to environmentally assisted cracking, (2021)

NACE, 0177-2016 Laboratory testing of metals for resistance to sulfide stress cracking and stress corrosion cracking in H2S environments, (2016)

C. Barbosa, J.L. Do Nascimento, J.L. Fernandes, I. De Cerqueira Abud, Failure analysis of two stainless steel based components used in an oil refinery. J. Fail. Anal. Prev. 8(4), 320–326 (2008)

T. Liu, R.W. Zhiyong, D. Xu, A.A. Aung, Metallurgical analysis on a cracked super duplex stainless steel flange. J. Fail. Anal. Prev. 14(4), 470–477 (2014)

DNV, RP-F112 Duplex stainless steel – design against hydrogen induced stress cracking, (2018)

D.R. Mclntyre, R.D. Kane, S.M. Wilhelm, Slow strain rate testing for materials evaluation in high-pressure H2S environments. Corrosion. 44(12), (1988)

A. Galakhova, K. Prattes, G. Mori, High-temperature high-pressure SCC testing of corrosion-resistant alloys. Mater. Corros. 72(12), 1831–1842 (2021)

C.M. Tseng, W.T. Tsai, H.Y. Liou, Effect of nitrogen content on the environmentally-assisted cracking susceptibility of duplex stainless steels. Metall. Mater. Trans. A. 34(1), 95–103 (2003)

I.H. Lo, W.T. Tsai, Effect of selective dissolution on fatigue crack initiation in 2205 duplex stainless steel. Corros. Sci. 49(4), 1847–1861 (2007)

X. Cheng, Y. Wang, X. Li, C. Dong, Interaction between austein-ferrite phases on passive performance of 2205 duplex stainless steel. J. Mater. Sci. Technol. 34(11), 2140–2148 (2018)

A. Bhattacharya, P.M. Singh, Stress corrosion cracking of welded 2205 duplex stainless steel in sulfide-containing caustic solution. J. Fail. Anal. Prev. 7(5), 371–377 (2007)

O.A. Hilders, M.G. Santana, Toughness and fractography of austenitic type 304 stainless steel with sensitization treatments at 973 K. Metallography. 21(2), 151–164 (1988)

Acknowledgments

Authors acknowledge to Brazilian research agencies CAPES and CNPq for financial support; to Fundação Carlos Chargas Filho de Amparo à Pesquisa do Estado do Rio de Janeiro FAPERJ (E-26/211.412/2021; E-26/200.122/2023; E-26/200.423/2023; E-26/204.777/2022) for financial support and the MCTI/SISNANO/INT-CENANO for the SSRT tests.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Gonzaga, A.C., Barros, T.S., Breves, I.M.S. et al. Characteristics of Cracking Propagation During Sulfide Stress Corrosion of Hot-Rolled Duplex Stainless Steel 2205. J Fail. Anal. and Preven. 24, 309–317 (2024). https://doi.org/10.1007/s11668-023-01838-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-023-01838-x