Abstract

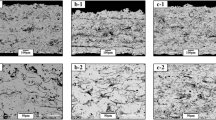

It was published that zirconate coatings containing Gd/Yb and yttria-stabilized zirconia (YSZ) coatings with high Y content had good calcium-magnesium-aluminum-silicate (CMAS) corrosion resistance. However, there are few reports on CMAS resistance of zirconia-based thermal barrier coatings (TBCs) doped with Y, Gd and Yb. This article intends to explore the role of Y, Gd and Yb in resisting CMAS corrosion of zirconia-based TBCs. The purpose is to optimize the rare earth modification of zirconia-based TBCs. 8YSZ and ZrO2-9.5Y2O3-5.6Yb2O3-5.2Gd2O3 free-standing TBCs were produced by air plasma spraying (APS) with commercial powders. The CMAS corrosion behavior and failure mechanism of these coatings were studied by heat treatment at 1350 °C. The microstructure and composition were characterized. The results showed the CMAS deposited on the surface of 8YSZ/YSZ-Yb-Gd coatings gradually penetrated into coatings. ZrSiO4 and m-ZrO2 were observed in the shallow layer of coatings. The diffusion rate of Y3+ in coatings into CMAS was greater than that of Gd3+ and Yb3+. Compared with YSZ coatings, CMAS penetrated deeper in YSZ-Yb-Gd coatings after the same corrosion time. The spallation of YSZ-Yb-Gd coatings occurred earlier than 8YSZ. In general, adding a small amount of Yb and Gd did not improve the CMAS resistance of YSZ TBCs.

Similar content being viewed by others

References

Y.Z. Liu and X.B. Hu, Segregation and Microstructural Evolution at Interfaces of Atmospheric Plasma Sprayed Thermal Barrier Coatings during Thermal Cycling, J. Alloys Compd., 2020, https://doi.org/10.1016/j.jallcom.2019.153026

U. Schulz, C. Leyens, K. Fritscher, M. Peters, B. Saruhan-Brings, O. Lavigne, J.M. Dorvaux, M. Poulain, R. Mévrel, and M. Caliez, Some Recent Trends in Research and Technology of Advanced Thermal Barrier Coatings, Aerosp. Sci. Technol., 2003, 7(1), p 73-80. https://doi.org/10.1016/S1270-9638(02)00003-2

D.G. Bogard and K.A. Thole, Gas Turbine Film Cooling, J. Propuls. Power., 2006, 22(2), p 249-270. https://doi.org/10.2514/1.18034

S.M. Meier, D.K. Gupta, and K.D. Sheffler, Ceramic Thermal Barrier Coatings for Commercial Gas Turbine Engines, JOM, 1991, 43(3), p 50-53. https://doi.org/10.1007/bf03220164

C.G. Levi, Emerging Materials and Processes for Thermal Barrier Systems, Curr. Opin. Solid State Mater. Sci., 2004, 8(1), p 77-91. https://doi.org/10.1016/j.cossms.2004.03.009

R. Vassen, A. Stuke, and D. Stöver, Recent Developments in the Field of Thermal Barrier Coatings, J. Therm. Spray Technol., 2009, 18(2), p 181-186. https://doi.org/10.1007/s11666-009-9312-7

J.L. Smialek and R.A. Miller, Revisiting the Birth of 7YSZ Thermal Barrier Coatings: Stephan Stecura, Coatings, 2018, 8(7), p 7-12. https://doi.org/10.3390/coatings8070255

B. Goswami, A.K. Ray, and S.K. Sahay, Thermal Barrier Coating System for Gas Turbine Application: A Review, High Temp. Mater. Process., 2004, 23(2), p 73-92. https://doi.org/10.1515/HTMP.2004.23.2.73

X. Ren and W. Pan, Mechanical Properties of High-Temperature-Degraded Yttria-Stabilized Zirconia, Acta Mater., 2014, 69, p 397-406. https://doi.org/10.1016/j.actamat.2014.01.017

A.M. Limarga, S. Shian, M. Baram, and D.R. Clarke, Effect of High-Temperature Aging on the Thermal Conductivity of Nanocrystalline Tetragonal Yttria-Stabilized Zirconia, Acta Mater., 2012, 60(15), p 5417-5424. https://doi.org/10.1016/j.actamat.2012.06.054

S.R. Choi, D. Zhu, and R.A. Miller, Mechanical Properties/Database of Plasma-Sprayed ZrO2-8wt% Y2O3 Thermal Barrier Coatings, Int. J. Appl. Ceram. Technol., 2004, 1(4), p 330-342. https://doi.org/10.1111/j.1744-7402.2004.tb00184.x

J.M. Drexler, A.L. Ortiz, and N.P. Padture, Composition Effects of Thermal Barrier Coating Ceramics on Their Interaction with Molten Ca-Mg-Al-Silicate (CMAS) Glass, Acta Mater., 2012, 60(15), p 5437-5447. https://doi.org/10.1016/j.actamat.2012.06.053

J.J. Hua, L.P. Zhang, Z.W. Liu, Y.Z. Wang, C.C. Lin, Y. Zeng, and X.B. Zheng, Progress of Research on the Failure Mechanism of Thermal Barrier Coatings, J. Inorg. Mater., 2012, 27(7), p 680-686. https://doi.org/10.3724/SP.J.1077.2012.11565 ((in Chinese))

A.R. Krause, H.F. Garces, G. Dwivedi, A.L. Ortiz, S. Sampath, and N.P. Padture, Calcia-Magnesia-Alumino-Silicate (CMAS)-Induced Degradation and Failure of air Plasma Sprayed Yttria-Stabilized Zirconia Thermal Barrier Coatings, Acta Mater., 2016, 105, p 355-366. https://doi.org/10.1016/j.actamat.2015.12.044

D.E. Mack, T. Wobst, M.O.D. Jarligo, D. Sebold, and R. Vaßen, Lifetime and Failure Modes of Plasma Sprayed Thermal Barrier Coatings in Thermal Gradient Rig Tests with Simultaneous CMAS Injection, Surf. Coat. Technol., 2017, 324, p 36-47. https://doi.org/10.1016/j.surfcoat.2017.04.071

H. Liu, J. Cai, and J. Zhu, CMAS (CaO-MgO-Al2O3-SiO2) Resistance of Y2O3-Stabilized ZrO2 Thermal Barrier Coatings with Pt Layers, Ceram. Int., 2018, 44(1), p 452-458. https://doi.org/10.1016/j.ceramint.2017.09.197

U. Schulz and W. Braue, Degradation of La2Zr2O7 and Other Novel EB-PVD Thermal Barrier Coatings by CMAS (CaO-MgO-Al2O3-SiO2) and Volcanic Ash Deposits, Surf. Coat. Technol., 2013, 235, p 165-173. https://doi.org/10.1016/j.surfcoat.2013.07.029

F. Wang, L. Guo, C. Wang, and F. Ye, Calcium-Magnesium-Alumina-SILICATE (CMAS) Resistance Characteristics of LnPO4 (Ln = Nd, Sm, Gd) Thermal Barrier Oxides, J. Eur. Ceram. Soc., 2017, 37(1), p 289-296. https://doi.org/10.1016/j.jeurceramsoc.2016.08.013

L. Gao, H. Guo, S. Gong, and H. Xu, Plasma-Sprayed La2Ce2O7 Thermal Barrier Coatings AGAINST Calcium-Magnesium-Alumina-Silicate Penetration, J. Eur. Ceram. Soc., 2014, 34(10), p 2553-2561. https://doi.org/10.1016/j.jeurceramsoc.2014.02.031

J.J. Cui, J.H. Ouyang, and Z.G. Liu, Hot Corrosion Behavior of LaMgAl11O19 Ceramic Coated with Molten CMAS Deposits at Temperature of 1250 °C in air, J. Alloys Compd., 2016, 685, p 316-321. https://doi.org/10.1016/j.jallcom.2016.05.272

L. Guo, M. Li, C. Yang, C. Zhang, L. Xu, F. Ye, C. Dan, and V. Ji, Calcium-Magnesium-Alumina-Silicate (CMAS) Resistance Property of BaLn2Ti3O10 (Ln = La, Nd) for Thermal Barrier Coating Applications, Ceram. Int., 2017, 43(13), p 10521-10527. https://doi.org/10.1016/j.ceramint.2017.05.107

J.M. Drexler, A.D. Gledhill, K. Shinoda, A.L. Vasiliev, K.M. Reddy, S. Sampath, and N.P. Padture, Jet Engine Coatings for Resisting Volcanic Ash Damage, Adv. Mater., 2011, 23(21), p 2419-2424. https://doi.org/10.1002/adma.201004783

L. Wei, L. Guo, M. Li, and H. Guo, Calcium-Magnesium-Alumina-Silicate (CMAS) Resistant Ba2REAlO5 (RE = Yb, Er, Dy) Ceramics for Thermal Barrier Coatings, J. Eur. Ceram. Soc., 2017, 37(15), p 4991-5000. https://doi.org/10.1016/j.jeurceramsoc.2017.06.004

M.H. Vidal-Sétif, C. Rio, D. Boivin, and O. Lavigne, Microstructural Characterization of the Interaction Between 8YPSZ (EB-PVD) Thermal Barrier Coatings and a Synthetic CAS, Surf. Coat. Technol., 2014, 239, p 41-48. https://doi.org/10.1016/j.surfcoat.2013.11.014

S. Krämer, J. Yang, C.G. Levi, and C.A. Johnson, Thermochemical Interaction of Thermal Barrier Coatings with Molten CaO-MgO-Al2O3-SiO2 (CMAS) Deposits, J. Am. Ceram. Soc., 2006, 89(10), p 3167-3175. https://doi.org/10.1111/j.1551-2916.2006.01209.x

W. Li, H. Zhao, X. Zhong, L. Wang, and S. Tao, Air Plasma-Sprayed Yttria and Yttria-Stabilized Zirconia Thermal Barrier Coatings Subjected to Calcium-Magnesium-Alumino-Silicate (CMAS), J. Therm. Spray Technol., 2014, 23(6), p 975-983. https://doi.org/10.1007/s11666-014-0107-0

F. Traeger, M. Ahrens, R. Vaßen, and D. Stöver, A Life Time Model for Ceramic Thermal Barrier Coatings, Mater. Sci. Eng. A, 2003, 358(1-2), p 255-265. https://doi.org/10.1016/S0921-5093(03)00300-9

Acknowledgments

This work was supported by the National Natural Science Foundation of China (NSFC) under the Grant No. 51701235, Science and Technology Innovation of Shanghai under the Grant No. 18511108702, and National Science and Technology Major Project under the Grant No. 2017-VI-0010-0082.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, T., Shao, F., Ni, J. et al. Calcium-Magnesium-Aluminum-Silicate (CMAS) Corrosion Resistance of Y-Yb-Gd-Stabilized Zirconia Thermal Barrier Coatings. J Therm Spray Tech 30, 442–456 (2021). https://doi.org/10.1007/s11666-020-01142-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-020-01142-2