Abstract

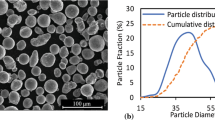

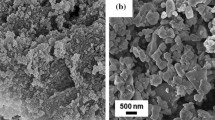

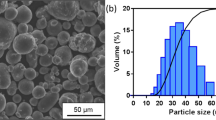

The vacuum kinetic spray (VKS) method is a relatively advanced technology by which thin and dense ceramic coatings can be fabricated via the high-speed impact of submicron-sized particles at room temperature. However, the actual bonding mechanism associated with the VKS process has not yet been elucidated. In this study, AlN powders were pretreated through ball-milling and heat-treatment processes in order to investigate the effects of microstructural changes on the deposition behavior. It was found that ball-milled and heat-treated powder with polycrystals formed by partially aligned dislocations showed considerably higher deposition rates when compared to only ball-milled powder with tangled dislocations. Therefore, in the VKS process, the deposition behavior is shown to be affected by not only the particle size and defect density, but also the microstructure of the feedstock powder.

Similar content being viewed by others

References

N. Setter, Electroceramics: Looking Ahead, J. Eur. Ceram. Soc., 2001, 21, p 1279-1293

Q.F. Zhou, H.L.W. Chan, and C.L. Choy, PZT Ceramic/Ceramic 0-3 Nanocomposite Films for Ultrasonic Transducer Applications, Thin Solid Films, 2000, 375, p 95-99

T. Haccart, E. Cattan, and D. Remiens, Dielectric, Ferroelectric and Piezoelectric Properties of Sputtered PZT Thin Films on Si Substrates: Influence of Film Thickness and Orientation, Semicond. Phys. Quantum Electron. Optoelectron., 2002, 5(1), p 78-88

Y. Sakashita, T. Ono, and H. Segawa, Preparation and Electrical Properties of MOCVD Deposited PZT Thin Films, J. Appl. Phys., 1991, 69(12), p 8352-8357

Z. An, C. Men, Z. Xu, P.K. Chu, and C. Lin, Electrical Properties of AlN Thin Films Prepared by Ion Beam Enhanced Deposition, Surf. Coat. Technol., 2005, 196, p 130-134

M. Jain, S.B. Majumder, R. Guo, A.S. Bhalla, and R.S. Katiyar, Synthesis and Characterization of Lead Strontium Titanate Thin Films by Sol-Gel Technique, Mater. Lett., 2002, 56, p 692-697

J. Akedo, Room Temperature Impact Consolidation (RTIC) of Fine Ceramic Powder by Aerosol Deposition Method and Applications to Microdevices, J. Therm. Spray. Technol., 2008, 17(2), p 181-198

S. Nam, N. Mori, H. Kakemoto, S. Wada, J. Akedo, and T. Tsurumi, Alumina Thick Films as Integral Substrates Using Aerosol Deposition Method, Jpn. J. Appl. Phys., 2004, 43(8A), p 5414-5418

J. Akedo, Aerosol Deposition of Ceramic Thick Films at Room Temperature: Densification Mechanism of Ceramic Layers, J. Am. Ceram. Soc., 2006, 89(6), p 1834-1839

Y.-Y. Wang, Y. Liu, G.-J. Yang, J.-J. Feng, and K. Kusumoto, Effect of Microstructure on the Electrical Properties of Nano-Structured TiN Coatings Deposited by Vacuum Cold Spray, J. Therm. Spray. Technol., 2010, 19(6), p 1231-1237

J. Akedo and M. Lebedev, Piezoelectric Properties and Poling Effect of Pb(Zr,Ti)O3 Thick Films Prepared for Microactuators by Aerosol Deposition, Appl. Phys. Lett., 2000, 77(11), p 1710-1712

J. Ryu, J. Choi, B. Hahn, D. Park, W. Yoon, and K. Kim, Fabrication and Ferroelectric Properties of Highly Dense Lead-Free Piezoelectric (K0.5Na0.5)NbO3 Thick Films by Aerosol Deposition, Appl. Phys. Lett., 2007, 90(15), p. 152901 (1-3)

X.-Y. Wang, C.-Y. Lee, C.-J. Peng, P.-Y. Chen, and P.-Z. Chang, A Micrometer Scale and Low Temperature PZT Thick Film MEMS Process Utilizing an Aerosol Deposition Method, Sens. Actuators A, 2008, 143, p 469-474

S.-Q. Fan, G.-J. Yang, C.-J. Li, G.-J. Liu, C.-X. Li, and L.-Z. Zhang, Characterization of Microstructure of Nano-TiO2 Coating Deposited by Vacuum Cold Spraying, J. Therm. Spray. Technol., 2006, 15(4), p 513-517

S.-Q. Fan, C.-J. Li, G.-J. Yang, L.-Z. Zhang, J.-C. Gao, and Y.-X. **, Fabrication of Nano-TiO2 Coating for Dye-Sensitized Solar Cell by Vacuum Cold Spraying at Room Temperature, J. Therm. Spray. Technol., 2007, 16(5-6), p 893-897

G.-J. Yang, C.-J. Li, K.-X. Liao, X.-L. He, S. Li, and S.-Q. Fan, Influence of Gas Flow During Vacuum Cold Spraying of Nano-Porous TiO2 Film by Using Strengthened Nanostructured Powder on Performance of Dye-Sensitized Solar Cell, Thin Solid Films, 2011, 519, p 4709-4713

J. Choi, J. Lee, D. Park, B. Hahn, W. Yoon, and H. Lin, Oxidation Resistance Coating of LSM and LSCF on SOFC Metallic Interconnects by the Aerosol Deposition Process, J. Am. Ceram. Soc., 2007, 90(6), p 1926-1929

J. Choi, D. Park, B. Seong, and H. Bae, Low-Temperature Preparation of Dense (Gd,Ce)O2-δ-Gd2O3 Composite Buffer Layer by Aerosol Deposition for YSZ Electrolyte-Based SOFC, Int. J. Hydrogen Energy, 2012, 37, p 9809-9815

J. Choi, K. Cho, J. Choi, J. Ryu, B. Hahn, J. Kim, C. Ahn, W. Yoon, J. Yun, and D. Park, Effects of Annealing Temperature on Solid Oxide Fuel Cells Containing (La,Sr)(Ga,Mg,Co)O3-δ Electrolyte Prepared by Aerosol Deposition, Mater. Lett., 2012, 17, p 44-47

S. Kim, D. Seo, and J. Lee, Fabrication of Xenogeneic Bone-Derived Hydroxyapatite Thin Film by Aerosol Deposition Method, Appl. Surf. Sci., 2008, 255, p 388-390

B. Hahn, D. Park, J. Choi, J. Ryu, W. Yoon, K. Kim, C. Park, and H. Kim, Dense Nanostructured Hydroxyapatite Coating on Titanium by Aerosol Deposition, J. Am. Ceram. Soc., 2009, 92(3), p 683-687

M. Lebedev, J. Akedo, and T. Ito, Substrate Heating Effects on Hardness of an α-Al2O3 Thick Film Formed by Aerosol Deposition Method, J. Cryst. Growth, 2005, 275, p e1301-e1306

D. Chun and S. Ahn, Deposition Mechanism of Dry Sprayed Ceramic Particles at Room Temperature Using a Nano-Particle Deposition System, Acta Mater., 2011, 59, p 2693-2703

D. Lee, H. Kim, Y. Kim, Y. Yun, and S. Nam, Growth Process of α-Al2O3 Ceramic Films on Metal Substrates Fabricated at Room Temperature by Aerosol Deposition, J. Am. Ceram. Soc., 2011, 94(9), p 3131-3138

W. Yong, G. Bae, K. Kang, and C. Lee, The Effect of Fracture-Induced Ceramic Free Surfaces for Vacuum Kinetic Spray Bonding, International Thermal Spray Conference, Sept 27-29, 2011 (Hamburg), DVS 276 Deutscher Verband für Schweißen, 2011, p 896-900

F. Cao, H. Park, G. Bae, J. Heo, and C. Lee, Microstructure Evolution of Titanium Nitride during Vacuum Kinetic Spraying, J. Am. Ceram. Soc., 2013, 96(1), p 40-43

Z.Q. Yang, L.L. He, and H.Q. Ye, The Effect of Ball Milling on the Microstructure of Ceramic AlN, Mater. Sci. Eng A, 2002, A323, p 354-357

A. Iwata, J. Akedo, and M. Lebedev, Cubic Aluminum Nitride Transformed Under Reduced Pressure Using Aerosol Deposition Method, J. Am. Ceran. Soc., 2005, 88(4), p 1067-1069

A. Iwata and J. Akedo, Hexagonal to Cubic Crystal Structure Transformation During Aerosol Deposition of Aluminum Nitride, J. Cryst. Growth, 2005, 275, p 1269-1273

S.G. Oleinik and N.V. Danilenko, Primary Recrystallization Mechanism in Ceramic Materials, Powder Metall. Met. Ceram., 1998, 37(1-2), p 63-77

R.W. Rice, Mechanical Properties of Ceramics and Composites: Grain and Particle Effects, Marcel Dekker, New York, 2000, p 54-57

B. Gludovatz, M. Faleschini, S. Wurster, A. Hoffmann, and R. Pippan, Influence of Microstructure on the Fracture Toughness of Tungsten Alloys, TMS Annual Meeting, Vol 1, New Orleans, 2008, p. 449-454

M. Janssen, J. Zuidema, and R. Wanhill, Fracture Mechanics, 2nd ed., Spon Press, New York, 2009, p 285-316

Acknowledgments

This work was supported by a Grant from the National Research Foundation of Korea (NRF) funded by the Korean Government (MEST) (No. 2012-0005448).

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is an invited paper selected from presentations at the 2012 International Thermal Spray Conference and has been expanded from the original presentation. It is simultaneously published in Thermal Spray 2012: Proceedings of the International Thermal Spray Conference, Air, Land, Water, and the Human Body: Thermal Spray Science and Applications, Houston, Texas, USA, May 21-24, 2012, Basil R. Marple, Arvind Agarwal, Laura Filofteia-Toma, Margaret M. Hyland, Yuk-Chiu Lau, Chang-Jiu Li, Rogerio S. Lima, and André McDonald, Ed., ASM International, Materials Park, OH, 2012.

Rights and permissions

About this article

Cite this article

Park, H., Heo, J., Cao, F. et al. Deposition Behavior and Microstructural Features of Vacuum Kinetic Sprayed Aluminum Nitride. J Therm Spray Tech 22, 882–891 (2013). https://doi.org/10.1007/s11666-013-9923-x

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-013-9923-x