Abstract

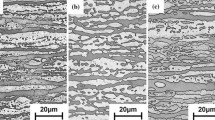

An economical Fe-Cr-Mn-Al duplex stainless steel not only has good thermos-plasticity, but also has excellent comprehensive mechanical properties. However, how to ensure that the prepared duplex stainless steel exhibits excellent corrosion resistance is crucial, therefore it becomes imperative to undertake a comprehensive study on the corrosion resistance of the duplex stainless steel and the underlying mechanisms that govern its behavior. This paper focuses on the influence of the phase fractions of ferrite and austenite on the pitting corrosion resistance of duplex stainless steel. The phase fraction is controlled by annealing treatment, and then the effect of phase ratio on the corrosion resistance of new Fe-Cr-Mn-Al duplex stainless steel and its related mechanism are revealed. The findings indicate that the alloying elements of ferrite and austenite in duplex stainless steel can be redistributed by adjusting the annealing temperature, and the difference of alloying elements distribution will inevitably change the pitting corrosion equivalent value of ferrite and austenite, thus affecting the pitting corrosion resistance of duplex stainless steel. It is found that the pitting corrosion resistance of new duplex stainless steel is determined by the galvanic corrosion rate between two phases.

Similar content being viewed by others

References

Y.C. Hsieh, L. Zhang, T.F. Chung, Y.T. Tsai, J.R. Yang, and T. Ohmura, In-Situ Transmission Electron Microscopy Investigation of the Deformation Behavior of Spinodal Nanostructured δ-Ferrite in a Duplex Stainless Steel, Scripta Mater., 2016, 125, p 44–48. https://doi.org/10.1016/j.scriptamat.2016.06.047

Z.Q. Zhang, H.Y. **g, L.Y. Xu, Y.D. Han, and L. Zhao, Investigation on Microstructure Evolution and Properties of Duplex Stainless Steel Joint Multi-pass Welded by Using Different Methods, Mater. Des., 2016, 109, p 670–685. https://doi.org/10.1016/j.matdes.2016.07.110

H. Tan, Y.M. Jiang, B. Deng, T. Sun, J.L. Xu, and J. Li, Effect of Annealing Temperature on the Pitting Corrosion Resistance of Super Duplex Stainless Steel UNS S32750, Mater charact., 2009, 60, p 1049–1054. https://doi.org/10.1016/j.matchar.2009.04.009

H. Luo, X.G. Li, C.F. Dong, and K. **ao, Effect of Solution Treatment on Pitting Behavior of 2205 Duplex Stainless Steel, Arab. J. Chem., 2017, 10, p S90–S94. https://doi.org/10.1016/j.arabjc.2012.06.011

S.-L. Lv, Z.-M. Yang, B. Zhang, J. Chen, Y. Chen, and X.-B. Li, Corrosion and Passive Behaviour of Duplex Stainless Steel 2205 at Different Cooling Rates in a Simulated Marine-Environment Solution, J. Iron. Steel Res. Int., 2018, 25, p 943–953. https://doi.org/10.1007/s42243-018-0136-x

L.C. An, J. Cao, L.C. Wu, H.H. Mao, and Y.T. Yang, Effects of Mo and Mn on Pitting Behavior of Duplex Steel, J. Iron. Steel Res. Int., 2016, 2016(23), p 1333–1341. https://doi.org/10.1016/S1006-706X(16)30196-0

H.D. Solomon and T.M. Devine, Proceedings of conference on Duplex Stainless Steels, ASM, Metal park, OH, 1983, p. 693.

D.H. Kang and H.W. Lee, Study of the Correlation between Pitting Corrosion and the Component Ratio of the Dual Phase in Duplex Stainless Steel Welds, Corros. Sci., 2013, 74, p 396–407. https://doi.org/10.1016/j.corsci.2013.04.033

K.H. Lo, C.H. Shek, and J.K.L. Lai, Recent Developments in Stainless Steels, Mater. Sci. Eng. R, 2009, 65, p 39–104. https://doi.org/10.1016/j.mser.2009.03.001

R.A. Perren, T.A. Suter, P.J. Uggowitzer, L. Weber, R. Magdowski, H. Bohni, H. Böhni, and M.O. Speidel, Corrosion Resistance of Super Duplex Stainless Steels in Chloride ion Containing Environments: Investigations by Means of a New Microelectrochemical Method I, Precipitation-Free States. Corros Sci., 2001, 43, p 707–726. https://doi.org/10.1016/S0010-938X(00)00087-1

I.H. Lo and W.T. Tsai, Effect of Selective Dissolution on Fatigue Crack Initiation in 2205 Duplex Stainless Steel, Corros. Sci., 2007, 49, p 1847–1861. https://doi.org/10.1016/j.corsci.2006.10.013

X.Q. Cheng, Y. Wang, X.G. Li, and C.F. Dong, Interaction Between Austein-Ferrite Phases on Passive Performance of 2205 Duplex Stainless Steel, J. Mater. Sci. Technol., 2018, 34(11), p 174–182. https://doi.org/10.1016/j.jmst.2018.02.020

H.Y. Ha, T.H. Lee, C.G. Lee, and H. Yoon, Understanding the Relation Between Pitting Corrosion Resistance and Phase Fraction of S32101 Duplex Stainless Steel, Corros. Sci., 2019, 149, p 226–235. https://doi.org/10.1016/j.corsci.2019.01.001

M.M. Pan, X.M. Zhang, P. Chen, X.B. Su, and R.D.K. Misra, The Effect of Chemical Composition and Annealing Condition on the Microstructure and Tensile Properties of a Resource-Saving Duplex Stainless Steel, Mater. Sci. Eng. A, 2020, 788, 139540. https://doi.org/10.1016/j.msea.2020.139540

H.Y. Ha, M.H. Jang, T.H. Lee, and J. Moon, Interpretation of the Relation Between Ferrite Fraction and Pitting Corrosion Resistance of Commercial 2205 Duplex Stainless Steel, Corros. Sci., 2014, 89, p 154–162. https://doi.org/10.1016/j.corsci.2014.08.021

L.H. Zhang, W. Zhang, Y.M. Jiang, B. Deng, D.M. Sun, and J. Li, Influence of Annealing Treatment on the Corrosion Resistance of Lean Duplex Stainless Steel 2101, Electrochim. Acta, 2009, 54(23), p 5387–5392. https://doi.org/10.1016/j.electacta.2009.04.023

L.Y. Zhu, Z.Y. Cui, H.Z. Cui, X. Wang, and Y.Z. Li, The Effect of Applied Stress on the Crevice Corrosion of 304 Stainless Steel in 3.5 wt% NaCl Solution, Corros. Sci., 2022, 196, p 110039. https://doi.org/10.1016/j.corsci.2021.110039

Y.J. Guo, T.Y. Sun, J.C. Hu, Y.M. Jiang, L.Z. Jiang, and J. Li, Microstructure Evolution and Pitting Corrosion Resistance of the Gleeble-Simulated Heat-Affected Zone of a Newly Developed lean Duplex Stainless Steel 2002, J. Alloy. Compd., 2016, 658, p 1031–1040. https://doi.org/10.1016/j.jallcom.2015.10.218

H.S. Isaacs, The Localized Breakdown and Repair of Passive Surfaces During Pitting, Corros. Sci., 1989, 29(2–3), p 313–323. https://doi.org/10.1016/0010-938X(89)90038-3

X.Q. Cheng, Y. Wang, C.F. Dong, and X.G. Li, The Beneficial Galvanic Effect of the Constituent Phases in 2205 Duplex Stainless Steel on the Passive Films Formed in a 3.5% NaCl Solution, Corros. Sci., 2018, 134, p 122–130. https://doi.org/10.1016/j.corsci.2018.02.033

Acknowledgments

This work was supported by the Liaoning Provincial Education Department Program (No. JYTMS20231162).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Pan, M., Zhang, J. & Zhang, X. The Relationship Between Phase Fraction and Pitting Corrosion Performance of a New Type of Fe-Cr-Mn-Al Duplex Stainless Steel. J. of Materi Eng and Perform (2024). https://doi.org/10.1007/s11665-024-09793-w

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-024-09793-w