Abstract

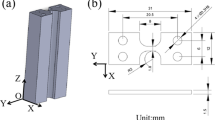

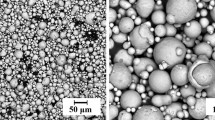

This study explores the influence of different shot peening (SP) durations on the microstructure and mechanical properties of 3D printed GH4169 alloy. This investigation examines the changes of microstructure and mechanical properties at different SP durations, and the following conclusions are drawn: (1) when the SP durations are 1, 3 and 5 min, the average thickness of the plastic deformation layer are approximately 84.6, 176.9, and 261.5 μm, respectively. This is mainly due to the influence of plastic strain and flow stress with the increase of SP duration. The grain size reaches its minimum value (approximately 3.7 μm) at 5 min. (2) The hardness values on the X0Y surface of 3D-printed GH4169 alloy are 549.2, 530.9 and 573.1HV, with the increase of SP duration from 1 to 5 min, respectively. (3) With the increase of SP duration, the yield strength of 3D printed GH4169 alloy is 765, 778 and 883 MPa, respectively. The total elongation under different SP treatments is 12.75, 14 and 10%.

Similar content being viewed by others

Data Availability

All data in this study are available from the corresponding author by request.

References

V.Y. Bhise and B.F. Jogi, Effect of Cutting Speed and Feed on Surface Roughness in Dry Turning of Inconel X-750, Mater. Today Proc., 2022, 61, p 587–592.

X.D. Lu, J.H. Du, Q. Deng, and J.Y. Zhuang, Stress Rupture Properties of GH4169 Superalloy, J. Mater. Res. Technol., 2014, 3, p 107–113.

D. Dong, K.Q. Shi, D.D. Zhu, Y.F. Liang, Z.J. Wei, and J.P. Lin, Microstructure Evolution and MECHANICAL properties of High Nb-TiAl Alloy/GH4169 Joints Brazed Using CuTiZrNi Amorphous Filler Alloy, Intermetallics, 2021, 139, 107351.

J.T. Luo, W.L. Yu, C.Y. **, C.X. Zhang, and C.H. Ma, Preparation of Ultrafine-Grained GH4169 Superalloy by High-Pressure Torsion and Analysis of Grain Refinement Mechanism, J. Alloys Compd., 2019, 777, p 157–164.

Y. Wang, W.Z. Shao, L. Zhen, L. Yang, and X.M. Zhang, Flow Behavior and Microstructures of Superalloy 718 During High Temperature Deformation, Mater. Sci. Eng. A, 2008, 497, p 479–486.

Y.C. Wang, L.M. Lei, L. Shi, F. Liang, H.Y. Wan, B. Zhang, and G.P. Zhang, Effect of Heat Treatment on Strain Hardening Ability of Selective Laser Melted Precipitation-Hardened GH4169 Superalloy, Mater Charact, 2022, 190, 112064.

C.L. Tan, F. Weng, S. Sui, Y.X. Chew, and G.J. Bi, Progress and Perspectives in Laser Additive Manufacturing of Key Aeroengine Materials, Int. J. Mach. Tool Manuf., 2021, 170, 103804.

A. Huang, L. Zhou, X.Q. Chen, and M. Gong, SMART Robotic System for 3D profile Turbine Vane Airfoil Repair, Int. J Adv. Manuf. Tech., 2003, 21, p 275–283.

O. Yilmaz, N. Gindy, and G. Jian, A Repair and Overhaul Methodology for Aeroengine Components, Robot Cim. Int. Manuf., 2010, 26, p 190–201.

T. DebRoy, H.L. Wei, J.S. Zuback, T. Mukherjee, J.W. Elmer, J.O. Milewski, A.M. Beese, A. Wilson-Heid, A. De, and W. Zhang, Additive Manufacturing of Metallic Components: Process, Structure and Properties, Prog. Mater. Sci., 2018, 92, p 112–224.

P. Yang, C.X. Liu, Q.Y. Guo, and Y.C. Liu, Variation of Activation Energy Determined by a Modified Arrhenius Approach: Roles of Dynamic Recrystallization on the Hot Deformation of Ni-Based Superalloy, J. Mater. Sci. Technol., 2021, 72, p 162–171.

L.C.M. Valle, A.I.C. Santana, M.C. Rezende, J. Dille, O.R. Mattos, and L.H. Almeida, The Influence of Heat Treatments on the Corrosion Behavior of Nickel-Based Alloy 718, J. Alloy. Compd., 2019, 809, 151781.

G.A. Qian, Z.M. Jian, X.N. Pan, and F. Berto, In-situ INVESTIGATION on fatigue Behaviors of Ti-6Al-4V Manufactured by Selective Laser Melting, Int. J. Fatigue, 2020, 13, 105424.

P. Edwards and M. Ramulu, Fatigue Performance Evaluation of Selective Laser Melted Ti-6Al-4V, Mater. Sci. Eng. A, 2014, 598, p 327–337.

V. Chastand, P. Quaegebeur, W. Maia, and E. Charkaluk, Comparative Study of Fatigue Properties of Ti-6Al-4V Specimens Built by Electron Beam Melting (EBM) and Selective Laser Melting (SLM), Mater Charact, 2018, 143, p 76–81.

S. Leuders, M. Thöne, A. Riemer, T. Niendorf, T. Tröster, H.A. Richard, and H.J. Maier, On the Mechanical Behaviour of Titanium Alloy TiAl6V4 Manufactured by Selective Laser Melting: Fatigue Resistance and Crack Growth Performance, Int. J. Fatigue, 2013, 48, p 300–307.

D. Herzog, V. Seyda, E. Wycisk, and C. Emmelmann, Additive Manufacturing of Metals, Acta Mater., 2016, 17, p 371–392.

L.F.S. Vieira, H.J.C. Voorwald, and M.O.H. Cioffi, Fatigue Performance of AISI 4340 Steel Ni-Cr-B-Si-Fe HVOF Thermal Spray Coated, Procedia Eng., 2015, 114, p 606–612.

Y.S. Nam, Y.I. Jeong, B.C. Shin, and J.H. Byun, Enhancing Surface Layer Properties of an Aircraft Aluminum Alloy by Shot Peening Using Response Surface Methodology, Mater. Design, 2015, 83, p 566–576.

B.G. Scuracchio, N.B. de Lima, and C.G. Schön, Role of Residual Stresses Induced by Double Peening on Fatigue Durability of Automotive Leaf Springs, Mater. Design, 2013, 47, p 672–676.

Y.H. Zhou, H.B. Yao, P.Y. Wei, A.X. Feng, X. He, J. Yue, W. Su, and W.H. Zhu, Study on Cavitation Erosion Resistance of Bimodal Grain Copper Alloy Fabricated by Laser Shock Peening, J. Mater., 2023, 25, p 1813–1823.

M. Mhaede, F. Pastorek, and B. Hadzima, Influence of Shot Peening on Corrosion Properties Of biocompatible Magnesium Alloy AZ31 Coated by Dicalcium Phosphate Dihydrate (DCPD), Mat. Sci. Eng. C., 2014, 39, p 330–335.

H.C. Yang, W. Zhang, X.C. Zhuang, and Z. Zhao, Anisotropic Plastic Flow of Low/Medium Carbon Steel Plates in Different Loading Conditions: Characterization of the r-Value, J. Mater. Process Tech., 2023, 321, 118159.

A. Evans, S.B. Kim, J. Shackleton, G. Bruno, M. Preuss, and P.J. Withers, Relaxation of Residual Stress in Shot peened Udimet 720Li Under High Temperature Isothermal Fatigue, Int. J. Fatigue, 2005, 27, p 1530–1534.

C.L. Xu, X. Wang, Y.X. Geng, Y.M. Wang, Z.W. Sun, B. Yu, Z.H. Tang, and S.L. Dai, Effect of Shot Peening on the Surface Integrity and Fatigue property of Gear Steel 16Cr3NiWMoVNbE at Room Temperature, Int. J. Fatigue, 2023, 172, 107668.

Z. Qin, B. Li, R. Chen, H. Zhang, H.Q. Xue, C.F. Yao, and L. Tan, Effect of Shot Peening on High Cycle and Very High Cycle Fatigue Properties of Ni-Based Superalloys, Int. J. Fatigue, 2023, 168, 107429.

H. Hou, R.F. Dong, Y.X. Tan, C.H. Li, X.Y. Zhang, L. Wu, B. Zhu, and Y.H. Zhao, Microstructural Characteristics and Enhanced Mechanical Properties of 2024 Aluminum Alloy Resulting from Shot-Peening Treatment, Mater Charact, 2023, 206, 113412.

H.H. Lai, H.C. Cheng, C.Y. Lee, C.M. Lin, and W. Wu, Effect of Shot Peening time on δ/γ Residual Stress Profiles of AISI 304 Weld, J. Mater. Process Tech., 2020, 284, 116747.

Z. Yanushkevich, S.V. Dobatkin, A. Belyakov, and R. Kaibyshev, Hall-Etch Relationship for Austenitic Stainless Steels Processed by Large Strain Warm Rolling, Acta Mater., 2017, 136, p 39–48.

X.H. Zhao, H.Y. Zhou, and Y. Liu, Effect of Shot Peening on the Fatigue Properties of Nickel-Based Superalloy GH4169 at High Temperature, Results Phys., 2018, 11, p 452–460.

H.J. Pan, W.Y. Tao, B. Zhang, P. Jiang, Z.Z. Wang, W.P. Wu, L. Liu, J. Li, Z.Q. Wu, and Z.H. Cai, Effect of Shot Peening Strengths on Microstructure and Mechanical Properties of 316L Stainless Steel Prepared by 3D Printing, Adv. Eng. Mater., 2023, 25, p 2201675.

H.J. Pan, P. Jiang, Y. Zhang, W.P. Wu, Z.Z. Wang, Q. Wang, and H.Y. Li, Microstructure and Mechanical Properties of a Novel Nb-Mo Bearing Medium-Mn Alloy Affected by Intercritical Annealing and Tempering, Mater. Sci. Eng. A, 2021, 802, p 140680.

H.J. Pan, W.Y. Tao, B. Zhang, P. Jiang, Z.Z. Wang, W.P. Wu, L. Liu, J. Li, Z.Q. Wu, and Z.H. Cai, Microstructure and Mechanical Properties of 3D-Printed 316L Stainless Steel at Different Shot Peening Durations. J. Mater. Eng. Perform.,2023.

H.J. Pan, Z. Wang, B. Zhang, P. Jiang, Z.Z. Wang, W.P. Wu, L. Liu, J. Li, Z.Q. Wu, and Z.H. Cai, Effect of Shot Peening on Microstructure and Mechanical Properties of 316L Stainless Steel Prepared by 3D Printing with Different Forming Angles. J. Mater. Eng. Perform., 2023.

Acknowledgments

The authors thank you for the project support from Ministry of Science and Technology of China (No. 52204382).

Author information

Authors and Affiliations

Contributions

Wenyu Tao: Conceptualization, Resources, Methodology, Writing—review & editing, Formal analysis, Supervision. Haijun Pan: Investigation, Data curation, Visualization, Writing original draft, Funding acquisition. Yi Zhao: Writing—review & editing, Supervision. Shunhu Zhang: Writing—review & editing, Supervision. Zhiqiang Wu: Writing—review & editing, Supervision. Zhihui Cai: Writing—review & editing, Supervision.

Corresponding authors

Ethics declarations

Conflict of interest

All authors state that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Tao, W., Pan, H., Zhao, Y. et al. Effect of Shot Peening Duration on Microstructure and Mechanical Properties of GH4169 Alloy Prepared by 3D Printing. J. of Materi Eng and Perform (2024). https://doi.org/10.1007/s11665-024-09686-y

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-024-09686-y