Abstract

This study investigates the microstructure evolution of inhomogenized 7050 aluminum alloy through hot compression tests performed on the Gleeble−3800 thermal simulation machine. The effects of deformation temperature, strain rate, and height reduction on the microstructure are studied using various analytical techniques including optical microscopy, electron backscatter diffraction (EBSD), and transmission electron microscopy. The results reveal that an increase in temperature enhances dynamic recovery and leads to an increase and subsequent decrease in the content of low-angle boundary (LAB) with a maximum value observed at 200 °C. Furthermore, the ratio and conversion amount of LAB decrease with a decrease in strain rate. The static recrystallization (SRX) is found to be strongly influenced by height reduction, and a 20% height reduction ensures complete SRX without grain growth. In order to evaluate the homogeneity of the microstructure, a coefficient (K) is introduced, and a novel method of microstructure homogeneity regulation is proposed based on both microstructure morphology characteristics and the coefficient (K). The study finds that microstructure homogeneity can be efficiently regulated by cumulative deformation of 20% height reduction and solution treatment in combination, with a deformation temperature of 200 °C at a strain rate of 1 s-1.

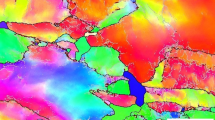

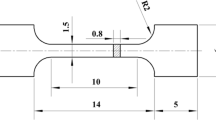

Graphical Abstract

Similar content being viewed by others

Data availability

The raw/processed data required to reproduce these findings cannot be shared at this time due to technical or time limitations.

References

Q.Y. Yang, Z.Q. Deng, Z.Q. Liu, Z.H. Jia, and G.J. Huang, Effects of Strain Rate on Flow Stress Behavior and Dynamic Recrystallization Mechanism of Al-Zn-Mg-Cu Aluminum Alloy During Hot Deformation, Mater. Sci. Eng. A, 2016, 662(4), p 204–213. https://doi.org/10.1016/j.msea.2016.03.027

H. Jianliang, Z. Zihan, B. Hong, J. Ziteng, and J. Mao, Quantitative Study of Dislocation Density Evolution of 7A85 Aluminum Alloy During Aging Treatment Process, Rare Met Mat. Eng., 2022, 51, p 1183–1187.

M. Safyari, M. Moshtaghi, and S. Kuramoto, On the Role of Traps in the Microstructural Control of Environmental Hydrogen Embrittlement of a 7xxx Series Aluminum Alloy, J. Alloys. Compd., 2021, 855, p 157300. https://doi.org/10.1016/j.jallcom.2020.157300

X.Y. Wang, H.E. Hu, and J.C. **a, Effect of Deformation Condition on Plastic Anisotropy of as-rolled 7050 Aluminum Alloy Plate, Mater. Sci. Eng. A, 2009, 515, p 1–9. https://doi.org/10.1016/j.msea.2009.03.061

T. Dursun and C. Soutis, Recent Developments in Advanced Aircraft Aluminum Alloys, Mater. Des., 2014, 56, p 862–869. https://doi.org/10.1016/j.matdes.2013.12.002

C.B. Li, S.L. Wang, D.Z. Zhang, S.D. Liu, Z.J. Shan, and X.M. Zhang, Effect of Zener-Hollomon Parameter on Quench Sensitivity of 7085 Aluminum Alloy, J. Alloys. Compd., 2016, 688, p 456–466. https://doi.org/10.1016/j.jallcom.2016.07.089

K.J. Fann and C.C. Chen, Grain Size in Aluminum Alloy 6061 under Hot Ring Compression Test and after T6 Temper, Appl. Sci., 2017, 7(4), p 372. https://doi.org/10.3390/app7040372

J.L. Hu, X.J. Wu, H. Bo, Z.T. Jiao, S.Q. Huang, and M. **, Dislocation Density Model and Microstructure of 7A85 Aluminum Alloy During Thermal Deformation, J. Cent. South Univ., 2021, 28, p 2999–3007. https://doi.org/10.1007/s11771-021-4832-5

A. Azarniya, A.K. Taheri, and K.K. Taheri, Recent Advances in Ageing of 7xxx Series Aluminum Alloys: A Physical Metallurgy Perspective, J. Alloys. Compd., 2019, 781, p 945–983. https://doi.org/10.1016/j.jallcom.2018.11.286

D. Ying, Z. Yin, and J. Huang, Hot Deformation Behavior and Microstructural Evolution of Homogenized 7050 Aluminum Alloy During Compression at Elevated Temperature, Mater. Sci. Eng. A, 2011, 528(3), p 1780–1786.

J. Luo, M.Q. Li, and D.W. Ma, The Deformation Behavior and Processing Maps in the Isothermal Compression of 7A09 Aluminum Alloy, Mater. Sci. Eng. A, 2012, 532, p 548–557. https://doi.org/10.1016/j.msea.2011.10.120

Q.Q. Zhu, L.F. Cao, Y.H. Liu, S.F. Liu, and X.D. Wu, Intergranular Micro-Deformation Behavior of a Medium Strength 7xxx Aluminum Alloy, J. Mater. Res. Technol., 2021, 12, p 471–477. https://doi.org/10.1016/j.jmrt.2021.02.098

H.E. Hu, L. Zhen, L. Yang, W.Z. Shao, and B.Y. Zhang, Deformation Behavior and Microstructure Evolution of 7050 Aluminum Alloy During High Temperature Deformation, Mater. Sci. Eng. A, 2008, 488, p 64–71. https://doi.org/10.1016/j.msea.2007.10.051

Y.F. Jiang, H. Ding, M.H. Cai, Y. Chen, Y. Liu, and Y.S. Zhang, Investigation into the Hot Forming-Quenching Integrated Process with cold dies for High Strength Aluminum Alloy, Mater. Charact., 2019, 158, p 109967. https://doi.org/10.1016/j.matchar.2019.109967

K. Huang, S. Huang, Y. Yi et al., Flow Behavior and Forming Characteristics of 2A14 Aluminum Alloy at Cryogenic Temperatures, J. Alloys. Compd., 2022, 902, p 163821.

X. Lei, Y. Zhang, J. Sun, F. Bachmann, X. Yang, R.E. Sanders, and J.D. Juul, Particle Stimulated Nucleation Revisited in Three Dimensions: A Laboratory-Based Multimodal x-ray Tomography Investigation, Mater. Res. Lett., 2021, 9(1), p 65–70. https://doi.org/10.1080/21663831.2020.1822455

G. Su, Z. Yun, Y.C. Lin, D.G. He, S. Zhang, and Z.J. Chen, Microstructure Evolution and a Unified Constitutive Model of Ti-55511 Alloy Compressed at Stepped Strain Rates, Materials, 2021, 14, p 6750. https://doi.org/10.3390/ma14226750

Y.Q. Jiang, Y.C. Lin, G.Q. Wang et al., Microstructure Evolution and a Unified Constitutive Model for a Ti-55511 Alloy Deformed in β Region, J. Alloys. Compd., 2021, 870(8), p 159534.

J.L. Hu, Z.H. Zhao, M.X. Dong, H. Wang, M. **, S.Q. Huang, and H. Bo, Microstructure Homogeneity Regulation of 7050 Aluminum Forgings by Surface Cumulative Plastic Deformation, Trans. Nonferrous Met. Soc. China, 2022, 32(09), p 2814–2827. https://doi.org/10.1016/S1003-6326(22)65985-5

K. Wang, D. Ren, X. Zan, L. Luo, X. Zhu, and Y. Wu, Recrystallization Behavior of Pure Tungsten Hot-Rolled with High Accumulated Strain During Annealing at 1250–1350 °C, Mater. Sci. Eng. A, 2021, 806(4), p 140828.

A.A. Benzerga, Y. Bréchet, A. Needleman, and E. Giessen, The Stored Energy of Cold Work: Predictions from Discrete Dislocation Plasticity, Acta Mater., 2005, 53(18), p 4765–4779.

H. Azzeddine, K. Tirsatine, T. Baudin, M.H. Mathon, A.L. Helbert, and F. Brisset, Bradai On the Stored Energy Evolution After Accumulative Roll-Bonding of Invar Alloy, Mater. Chem. Phys., 2017, 201, p 408–415.

M. El-Tahawy, Y. Huang, T. Um, H. Choe, J.L. Lábár, T.G. Langdon, and J. Gubicza, Stored Energy in Ultrafine-Grained 316L Stainless Steel Processed by High-Pressure Torsion, J. Mater. Res. Technol., 2017, 6(4), p 339–347.

S.S. Hazra, A.A. Gazder, and E.V. Pereloma, Stored Energy of a Severely Deformed Interstitial Free Steel, Mater. Sci. Eng. A, 2019, 524(1), p 158–167.

T. Vershinina and M. Leont’Eva-Smirnova, Dislocation Density Evolution in the Process of High-Temperature Treatment and Creep of EK-181 Steel, Mater. Charact., 2017, 125, p 23–28. https://doi.org/10.1016/j.matchar.2017.01.018

T. Shintani and Y. Murata, Evaluation of the Dislocation Density and Dislocation Character in Cold Rolled Type 304 Steel Determined by Profile Analysis of x-ray Diffraction, Acta Mater., 2011, 59, p 4314–4322. https://doi.org/10.1016/j.actamat.2011.03.055

S. Takebayashi, T. Kunieda, and N. Yoshinaga, Comparison of the Dislocation Density in Martensitic Steels Evaluated by Some x-ray Diffraction Methods, ISIJ Int., 2010, 50, p 875–882. https://doi.org/10.2355/isi**ternational.50.875

W.W. Song, J.F. Pu, H.F. Wang, D. Jiang, L. Bao, and W.D. Chen, Effect of Solid-Solution Process on the Properties of 7050 Aluminum Alloy, Key Eng. Mater., 2020, 866, p 63–71. https://doi.org/10.4028/www.scientific.net/KEM.866.63

Q.S. Bai, J.X. Bai, and C. Hu, Investigation on the Dislocation Evolution in Nanoindentation with 25D Discrete Dislocation Dynamics Simulation and Experiment, Mater. Sci. Eng. A, 2018, 730, p 84–91. https://doi.org/10.1016/j.msea.2018.05.062

Y. Deng, Z.M. Yin, and J.W. Huang, Hot Deformation Behavior and Microstructural Evolution of Homogenized 7050 Aluminum Alloy During Compression at Elevated Temperature, Mater. Sci. Eng. A, 2010, 528, p 1780–1786. https://doi.org/10.1016/j.msea.2010.11.016

J. Envelope, L. Xun, and T. Wang, The Effects of Ultrasonic Vibration on Portevin–Le Chatelier (PLC) Effect and Stress-Strain Behavior in Aluminum Alloy 2024, Scr. Mater., 2023, 224(2), p 115121.

Y. Choi, J. Ha, M.G. Lee et al., Observation of Portevin-le Chatelier Effect in Aluminum Alloy 7075-w Under a Heterogeneous Stress Field, Scr. Mater., 2021, 205(12), p 114–178.

F. Dong, Y.P. Yi, S.Q. Huang, S.L. Gao, Y.Z. Jia, and W.W. Yu, A Dislocation Density-Based Model Considering Dynamic Strain Aging for Annealed and Water-Quenched Aluminum Alloys Under Low-temperature Conditions, Mater. Sci. Eng. A, 2022, 855(10), p 143916.

A. Standards. Standard Test Methods for Determining Average Grain Size: ASTM E112-10, PA: ASTM Int. 2010.

Acknowledgments

This work was supported by Natural Science Foundation of Hebei Province (Grant No. E2019203075 and E2021203059), National Natural Science Foundation of China (Grant No. 52171018), Top Young Talents Project of the Education Department of Hebei Province (Grant No. BJ2019001)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhao, Z., Hu, J., **ng, C. et al. Microstructural Evolution and Regulation of Inhomogenized 7050 Aluminum Alloy during Compression at Low Temperature. J. of Materi Eng and Perform (2023). https://doi.org/10.1007/s11665-023-08494-0

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-023-08494-0