Abstract

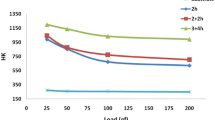

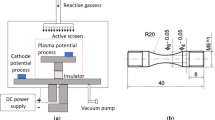

A hydrogen-free surface nitriding process was proposed to enhance the wear properties of TiZrAlV alloy by using double-glow plasma. The structure, morphology, composition, hardness, tribological behavior and corrosion properties of nitrided TiZrAlV alloy have been systematically characterized. A dense and continuous nitrided layer, with a thickness of 110 μm, was formed on the surface of TiZrAlV alloy, mainly containing TiN, and Ti2N phases. The surface hardness of nitrided TiZrAlV alloy was 1437HV, which is 4 times higher than that of as-received alloy. The formation of high-hardness nitrides phases results in remarkable amelioration in specific wear rate and wear resistance of TiZrAlV alloy after nitriding. Moreover, the corrosion resistance of nitrided TiZrAlV alloy, measured in 1 M HCl and 3.5 wt.% NaCl solutions, has been significantly increased. The nitriding treatment reduced the relative proportion of the weight loss after being immersed in 2 M HCl solution.

Similar content being viewed by others

References

A.V. Tyunkov, D.A. Golosov et al., Nitriding of Titanium in Electron Beam Excited Plasma in Medium Vacuum, Surf. Coat. Technol., 2020, 383, p 125241.

P. Kwasniak and H. Garbacz, Screw Dislocation Mediated Solution Strengthening of Substitutional α-Ti Alloys–First Principles Investigation, Acta Mater., 2017, 141, p 405–418.

Y. Yang, R.-R. Chen et al., Improving Microstructure and Mechanical Properties of Alloy Ti43Al5Nb0.1B by Addition of Fe, Rare Met., 2019, 38, p 1024.

R. **g, S.X. Liang et al., Effect of the Annealing Temperature on the Microstructural Evolution and Mechanical Properties of TiZrAlV Alloy, Mater. Des., 2013, 52, p 981–986.

S.X. Liang, Z.H. Feng et al., The Effects of V Content on the Microstructure and Mechanical Properties of Hot Rolled TiZr Based Alloys, J. Alloys Compd., 2016, 664, p 11–18.

Z.-H. Feng, X.-Y. Sun et al., Microstructure and Microhardness of a Novel TiZrAlV Alloy by Laser Gas Nitriding at Different Laser Powers, Rare Met., 2020, 39, p 270–278.

G.-S. Zhang, D.-F. Guo, M. Li et al., Tailoring Microstructure and Tribological Properties of Cold Deformed TiZrAlV Alloy by Thermal Treatment, Acta Metall. Sin., 2016, 10, p 1007.

H. Zhong, L.Y. Dai, Y. Yue et al., Friction and Wear Behavior of Annealed Ti-20Zr-65Al-4V Alloy Sliding Against 440C Steel in Vacuum, Tribol Int., 2017, 109, p 571–577.

A. Nishimoto, H. Nii et al., Simultaneous Duplex Process of TiN Coating and Nitriding by Active Screen Plasma Nitriding, Surf. Coat. Technol., 2013, 228, p S558–S562.

S. Ahmed, D. Chakrabarty et al., Plasma Nitriding on Titanium Surface for Adhesion Promotion, Surf. Eng., 2015, 31, p 616–622.

D. Rodriguez, F.J. Gil, and J.A. Planell, Wear Resistance of the Nitrogen Diffusion Hardening of the Ti-6Al-4V alloy, J. Biomech., 1998, 1001, p 49.

P. Olsson, K. Kese et al., On the Role of Hydrogen Filled Vacancies on the Embrittlement of Zirconium: An ab Initio Investigation, Nucl. Mater., 2015, 467, p 311–319.

E. Galvanetto, F.P. Galliano et al., Corrosion Resistance Properties of Plasma Nitrided Ti-6Al-4V Alloy in Hydrochloric Acid Solutions, Corros. Sci., 2002, 44, p 1593–1606.

Z. Xu, X. Liu, P. Zhan et al., Double Glow Plasma Surface Alloying and Plasma Nitriding, Surf. Coat. Technol., 2007, 201, p 4822–4825.

X.Y. Ai, H.L. Lin et al., Hydrogen-Free Nitriding of ZrTiAlV by Double Glow Plasma Discharge Improving the Wear Resistance, Mater. Sci. Technol., 2018, 34, p 1303–1305.

N.S. Mashovets, I.M. Pastukh, and S.M. Voloshko, Aspects of the Practical Application of Titanium Alloys after Low Temperature Nitriding Glow Discharge in Hydrogen-Free-Gas Media, Appl. Surf. Sci., 2017, 392, p 356–361.

A. Zhecheva, W. Sha, S. Malinov, and A. Long, Enhancing the Microstructure and Properties of Titanium Alloys through Nitriding and Other Surface Engineering Methods, Surf. Coat. Technol., 2005, 200, p 2192–2207.

F. Zhang, M. Yan et al., Influence of Plasma Nitriding Temperature on Microstructures and Mechanical Properties of Ti-N/Ti-Al Multilayer Coatings on the Surface of 5083 Al Alloys, Surf. Coat. Technol., 2018, 335, p 80–87.

M. Gushchina, T. Carstensen et al., Plasma Nitriding Ti-6Al-4V with the Aid Non-Transmitted Plasma-Arc using Different Protection Atmosphere, Mater. Today Proc., 2020, 30, p 694–699.

T. Suzuki, D. Huang, and Y. Ikuhara, Microstructures and Grain Boundaries of (Ti, Al)N Films, Surf. Coat. Technol., 1998, 107, p 41–47.

S. Semboshi, S. Kimura, A. Iwase, and N. Ohtsu, Surface Hardening of Age-Hardenable Cu-Ti Dilute Alloys by Plasma Nitriding, Surf. Coat. Technol., 2014, 258, p 691–698.

M.N. Gardos, The Effect of Anion Vacancies on the Tribological Properties of Rutile (TiO2-x), Tribol. Trans., 2008, 31, p 427–436.

M.N. Gardos et al., The Effect of Anion Vacancies on the Tribological Properties of Rutile (TiO2-x), Part II: Experimental Evidence, Tribol. Trans., 2008, 33, p 209–220.

T.F.J. Quinn, J.L. Sullivan, and D.M. Rowson, Origins and development of oxidational wear at low ambient temperatures, Wear, 1984, 94, p 175–191.

L. Liu, H.H. Shen et al., Wear Resistance of TiN(Ti2N)/Ti Composite Layer Formed on C17200 Alloy by Plasma Surface Ti-Alloying and Nitriding, Appl. Surf. Sci., 2016, 388, p 103–108.

S.K. Yen, S.H. Chiou, S.J. Wu, C.C. Chang, S.P. Lin, and C.M. Lin, Characterization of Electrolytic HA/ZrO2 Double Layers Coatings on Ti-6Al-4V Implant Alloy, Mater. Sci. Eng., 2006, 26, p 65–77.

O.S. Adesina, B.A. Obadele et al., Influence of Phase Composition and Microstructure on Corrosion Behavior of Laser Based Ti-Co-Ni Ternary Coatings on Ti-6Al-4V Alloy, J. Alloys Compd., 2020, 827, p 154245.

S. Zhou, Y. Zhao et al., Enhanced Corrosion Resistance of Ti-5 wt.% TiN Composite Compared to Commercial Pure Ti Produced by Selective Laser Melting in HCl Solution, J. Alloys Compd., 2020, 820, p 153422.

R. Kumari and J.D. Majumdar, Studies on Corrosion Resistance and Bio-Activity of Plasma Spray Deposited Hydroxylapatite (HA) Based TiO2 and ZrO2 Dispersed Composite Coatings on Titanium Alloy (Ti-6Al-4V) and the Same After Post Spray Heat Treatment, Appl. Surf. Sci., 2017, 420, p 935–943.

C. Haixiang and K. Dejun, Comparison on Electrochemical Corrosion Performances of Arc and Laser Thermal Sprayed Al-Ti-Ni Coatings in Marine Environment, Mater. Chem. Phys., 2020, 251, p 12320.

Y. Chen, X. Nie, and D.O. Northwood, Plasma Electrolytic Oxidation (PEO) Coatings on a Zirconium Alloy for Improved Wear and Corrosion Resistance, WIT Trans. Eng. Sci., 2010, 66, p 183.

D.D. Macdonald, The History of the Point Defect Model for the Passive State: A Brief Review of Film Growth Aspects, Electrochim. Acta, 2001, 56, p 1761–1772.

J. Geringer and D.D. Macdonald, Modeling Fretting-Corrosion Wear of 316L SS Against poly(methyl methacrylate) with the Point Defect Model: Fundamental Theory, Assessment, and Outlook, Electrochim. Acta, 2012, 79, p 17–30.

D. Digby, Macdonald, Some Personal Adventures in Passivity—a Review of the Point Defect Model for Film Growth, Russ. J. Electrochem., 2012, 48, p 235–258.

A.M. Fekry, The Influence of Chloride and Sulphate Ions on the Corrosion Behavior of Ti and Ti-6Al-4V Alloy in Oxalic Acid, Electrochim. Acta, 2009, 54, p 3480–3489.

D. Sazou, K. Saltidou, and M. Pagitsas, Understanding the Effect of Bromides on the Stability of Titanium Oxide Films Based on a Point Defect Model, Electrochim. Acta, 2012, 76, p 48–61.

R. Narayanan and S.K. Seshadri, Point Defect Model and Corrosion of Anodic Oxide Coatings on Ti-6Al-4V, Corros. Sci., 2008, 50, p 1521–1529.

Z. Jiang, X. Dai, T. Norby, and H. Middleton, Investigation of Pitting Resistance of Titanium Based on a Modified Point Defect Model, Corros. Sci., 2011, 53, p 815–821.

G. Ansari and A. Fattah-Alhosseini, On the Passive and Semiconducting Behavior of Severely Deformed Pure Titanium in Ringer’s Physiological Solution at 37 °C: A Trial of the Point Defect Model, Mater. Sci. Eng. C, 2017, 75, p 64–71.

Acknowledgments

This work was supported by the NSFC (Grant no.51531005/51571174).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lv, J.W., Ai, X.Y., Zhang, B. et al. Hydrogen-Free Plasma Nitriding to Enhance Wear and Corrosion Resistance of TiZrAlV Alloy. J. of Materi Eng and Perform 33, 54–63 (2024). https://doi.org/10.1007/s11665-023-08151-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-023-08151-6