Abstract

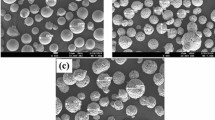

In order to improve the wear resistance of medium-carbon steel, a dense WC-10Co-4Cr coating was prepared by high-velocity oxygen fuel (HVOF) spraying. The results show that the thickness of WC-10Co-4Cr coating is about 200 μm, which is mainly composed of WC, W2C, Co, Cr and Co6W6C phases, and its hardness is about 4.4 times higher than that of medium-carbon steel. The impact wear behavior of medium-carbon steel and WC-10Co-4Cr coating under ball-on-flat contact mode was systematically studied by using Si3N4 ball as impact pair. The results show that the deposition of WC-10Co-4Cr coating can significantly reduce the plastic damage and oxidation of the worn surface, thus inhibiting the initiation, propagation and connection of microcracks, as well as the crushing and spalling of surface materials. When the initial kinetic energy reaches 1.84 mJ, the width and depth of wear trace, wear volume and wear rate of WC-10Co-4Cr coating are about 96.01, 4.51, 4.17 and 4.98% of those of medium-carbon steel, respectively. In addition, the dominant wear mechanism of medium-carbon steel is plastic deformation, fatigue wear and oxidation, while the main wear mechanism of WC-10Co-4Cr coating is delamination and slight oxidation.

Access this article

We’re sorry, something doesn't seem to be working properly.

Please try refreshing the page. If that doesn't work, please contact support so we can address the problem.

Similar content being viewed by others

References

H.B. Han, S.Z. Du, Y.Z. Zhang, H. Liu, and R.M. Pan, Effect of DC Magnetic Field on Friction and Wear Properties of 45 Steel at Different Velocities, Tribol. Lett., 2016, 64, p 38.

H.B. Han, Y.K. Gao, Y.Z. Zhang, S.M. Du, and H. Liu, Effect of Magnetic Field Distribution of Friction Surface on Friction and Wear Properties of 45 Steel in DC Magnetic Field, Wear, 2015, 328–329(15), p 422–435.

Q.Y. Zhang, K.M. Chen, L. Wang, X.H. Cui, and S.Q. Wang, Characteristics of Oxidative Wear and Oxidative Mildwear, Tribol. Int., 2013, 61, p 214–223.

X.X. Yang, Low Cycle Fatigue and Cyclic Stress Ratcheting Failure Behavior of Carbon Steel 45 Under Uniaxial Cyclic Loading, Int. J. Fatigue, 2005, 27(9), p 1124–1132.

S. Klein, L.M. Roncery, M. Walter, S. Weber, and W. Theisen, Diffusion Processes During Cementite Precipitation and their Impact on Electrical and Thermal Conductivity of a Heat-Treatable Steel, J. Mater. Sci., 2017, 52(1), p 375–390.

G.H. Zhou, Y.F. Zhu, X.M. Wang, M.J. **a, Y. Zhang, and H.Y. Ding, Sliding Tribological Properties of 0.45% Carbon Steel Lubricated with Fe3O4 Magnetic Nano-Particle Additives in Baseoil, Wear, 2013, 301(1), p 753–757.

Y.L. **e, C. Sun, Y.Z. Zhang, H.X. Shi, C.F. Song, and S.M. Du, Effect of Magnetic Oxidation and Surface Carbon Distribution on Friction and Wear Characteristics of 45 Steel Under the DC Magnetic Field, Tribol. Trans., 2019, 62(5), p 1–13.

W. Cai, F.N. Meng, X.Y. Gao, and J. Hu, Effect of QPQ Nitriding Time on Wear and Corrosion Behavior of 45 Carbon Steel, Appl. Surf. Sci., 2012, 261(15), p 411–414.

J. Terva, T. Teeri, V.T. Kuokkala, P. Siitonen, and J. Liimatainen, Abrasive Wear of Steel Against Gravel with Different Rock-Steel Combinations, Wear, 2009, 267(11), p 1821–1831.

J. Rendón and M. Olsson, Abrasive Wear Resistance of Some Commercial Abrasion Resistant Steels Evaluated by Laboratory Test Methods, Wear, 2009, 267(11), p 2055–2061.

W.L. Zhao, H. Huang, and Z.L. Wang, Investigation about Electro-Deposition Properties of Special Nickel Electroplating Coating for 45# Steel with Different Surface Roughnesses, Advanced Materials Research, 2011, 146–147, p 962–965.

Y. Sui, F. Yang, G. Qin, Z. Ao, Y. Liu, and Y. Wang, Microstructure and Wear Resistance of Laser-Cladded Ni-based Composite coatings on Downhole Tools, J. Mater. Process. Technol., 2017, 252, p 217–224.

J. Ma, D.Q. Yan, J.W. Hu, X. Zhang, and Y. Li, Reactive HVOF Sprayed TiN-Matrix Composite Coating and Its Corrosion and Wear Resistance Properties, Trans. Nonferrous Met. Soc. China, 2013, 23(4), p 1011–1018.

K. Goyal, Mechanical Properties and Erosive Behaviour of 10TiO2-Cr2O3 Coated CA6NM Turbine Steel Under Accelerated Conditions, World J. Eng., 2019, 16(1), p 64–70.

N. Vashishtha, R.K. Khatirkar, and S.G. Sapate, Tribological Behaviour of HVOF Sprayed WC-12Co, WC-10Co-4Cr and Cr3C2−25NiCr Coatings, Tribol. Int., 2016, 105, p 55–68.

A.C. Savarimuthu, H.F. Taber, I. Megat, J.R. Shadley, E.F. Rybicki, W.C. Cornell, W.A. Emery, D.A. Somerville, and J.D. Nuse, Sliding Wear Behavior of Tungsten Carbide Thermal Spray Coatings for Replacement of Chromium Electroplate in Aircraft Applications, J. Therm. Spray Technol., 2001, 10(3), p 502–510.

A.C. Karaoglanli, M. Oge, K.M. Doleker, and M. Hotamis, Comparison of Tribological Properties of HVOF Sprayed Coatings with Different Composition, Surf. Coat. Technol., 2017, 318(25), p 299–308.

G. Bolelli, L.M. Berger, M. Bonetti, and L. Lusvarghi, Comparative Study of the Dry Sliding Wear Behaviour of HVOF-Sprayed WC-(W, Cr)2C-Ni and WC-CoCr Hardmetal Coatings, Wear, 2014, 39(1–2), p 96–111.

H. Singh, K. Goyal, and D.K. Goyal, Slurry Erosion Behaviour of Plasma Thermal Sprayed (50%) WC-Co-Cr and Ni-Cr-B-Si Coatings of Different Thickness on CA6NM Turbine Steel Material, Manuf. Sci. Technol., 2014, 2(4), p 81–92.

R. Kumar, K. Goyal, and D. Bhandari, Slurry Erosion Behavior of Thermally Sprayed Ceramic Nanocomposite Coatings on Turbine Steel, Int. J. Appl. Ceram. Technol., 2022, 19(6), p 3049–3061.

N. Vashishtha, S.G. Sapate, J.S. Gahlot, and P. Bagde, Effect of Tribo-Oxidation on Friction and Wear Behaviour of HVOF Sprayed WC-10Co-4Cr Coating, Tribol. Lett., 2018, 66(2), p 1–19.

Z. Kamdi, P.H. Shipway, K.T. Voisey, and A.J. Sturgeon, Abrasive Wear Behaviour of Conventional and Large-Particle Tungsten Carbide-Based Cermet Coatings as a Function of Abrasive Size and Type, Wear, 2011, 271(9–10), p 1264–1272.

V. Ra**ikanth and K. Venkateswarlu, An Investigation of Sliding Wear Behaviour of WC-Co Coating, Tribol. Int., 2011, 44(12), p 1711.

J.A. Picas, M. Punset, M.T. Baile, E. Martín, and A. Forn, Effect of Oxygen/Fuel Ratio on the In-Flight Particle Parameters and Properties of HVOF WC-CoCr Coatings, Surf. Coat. Technol., 2011, 205, p S364–S368.

Y.P. Wu, B. Wang, S. Hong, J.F. Zhang, Y.J. Qin, and G.Y. Li, Dry Sliding Wear Properties of HVOF Sprayed WC-10Co-4Cr Coating, Trans. Indian Inst. Met., 2015, 68(4), p 581–586.

J.F. Zheng, J. Luo, J.L. Mo, J.F. Peng, and M.H. Zhu, Fretting Wear Behaviors of a Railway Axle Steel, Tribol. Int., 2010, 43(5), p 906–911.

J. Hintikka, A. Lehtovaara, and A. Mäntylä, Fretting-Induced Friction and Wear in Large Flat-on-Flat Contact with Quenched and Tempered Steel, Tribol. Int., 2015, 92, p 191–202.

Y. Duan, S. Qu, S. Jia, and X. Li, Fretting Wear Behavior of the High-Carbon High-Chromium X210CrW12 Steel: Influence of Counterbody Material, Wear, 2021, 486–487, p 204080.

Z. Han, Y.S. Zhang, and K. Lu, Friction and Wear Behaviors of Nanostructured Metals, J. Mater. Sci. Technol., 2008, 24(4), p 483–494.

M.N. Kotzalas and G.L. Doll, Tribological Advancements for Reliable Wind Turbine Performance, Philos. Trans., 2010, 368(1929), p 4829–4850.

L. Ma, K. Eom, J. Geringer, T.S. Jun, and K. Kim, Literature Review on Fretting Wear and Contact Mechanics of Tribological Coatings, Coatings, 2019, 9(8), p 501.

F. Abbasi, G.H. Majzoobi, and J. Mendiguren, A Review of the Effects of Cyclic Contact Loading on Fretting Fatigue Behavior, Adv. Mech. Eng., 2020, 12(9), p 1–17.

Z. Wang, Z.B. Cai, Y. Sun, J.F. Peng, and M.H. Zhu, Low Velocity Impact Wear Behavior of MoS 2 /Pb Nanocomposite Coating Under Controlled Kinetic Energy, Surf. Coat. Technol., 2017, 326, p 53–62.

W.J. Yang, L. Zou, X.Y. Cao, J.H. Liu, D.J. Li, and Z.B. Cai, Fretting Wear Properties of HVOF-Sprayed CoMoCrSi Coatings with Different Spraying Parameters, Surf. Coat. Technol., 2019, 358, p 994–1005.

R.D. Castro, E.I.M. Curi, L.F.F. Inacio, A.D. Rocha, M. Pereira, R.G.N. Silva, and A.D.P. Pereira, Laser Remelting of WC-CoCr Surface Coated by HVOF: Effect on the Tribological Properties and Energy Efficiency, Surf. Coat. Technol., 2021, 427, p 127841.

Z. Wang, Z. Cai, B.Z. Chen, Q.Y. Sun, and M.H. Zhu, Low-Velocity Impact Wear Behavior of Ball-to-Flat Contact Under Constant Kinetic Energy, J. Mater. Eng. Perform., 2017, 26(11), p 5669–5679.

S. Yang, Z.B. Cai, Z.Q. Chen, H. Qian, and M.H. Zhu, Impact Fretting Wear of Inconel 690 Tube with Different Supporting Structure Under Cycling Low Kinetic Energy, Wear, 2017, 376–377, p 625–633.

Y.B. Zhang, L.T. Lu, L. Zou, D.F. Zeng, and J.W. Zhang, Finite Element Simulation of the Influence of Fretting Wear on Fretting Crack Initiation in Press-Fitted Shaft Under Rotating Bending, Wear, 2018, 400, p 177–183.

D. Zeng, Y. Zhang, L. Lu, L. Zou, and S. Zhu, Fretting Wear and Fatigue in Press-Fitted Railway Axle: A Simulation Study of the Influence of Stress Relief Groove, Int. J. Fatigue, 2018, 118, p 225–236.

J. Li, B.B. Yang, Y.H. Lu, L. **n, Z.H. Wang, and T. Shoji, The Degradation Mechanism of Inconel 690TT Induced by Fretting Wear in Air, Tribol. Int., 2017, 116, p 147–154.

B.X. Liu, K.Y. Fan, F.X. Yin, J.H. Feng, and P.G. Ji, Effect of Caliber Rolling Reduction Ratios on the Microstructure and Mechanical Properties of 45 Medium Carbon Steel, Mater. Sci. Eng. A, 2020, 774, p 138954–138954.

H. Attia, A Generalized Fretting Wear Theory, Tribol. Int., 2009, 42(9), p 1380–1388.

Acknowledgments

This work was supported by Key Research and Development Program of Jiangxi Province (20171ACE50018), Fund Project of Jiangxi Provincial Department of Education (GJJ210651), National Natural Science Foundation of China (no. 51805170) and Science Fund for Distinguished Young Scholars of Jiangxi Province (no. 20212ACB214003). In particular, the authors would like to thank Dr. Fan Kunyang in the College of Mechanical Engineering of Chengdu University for her generous supply of raw materials.

Author information

Authors and Affiliations

Ethics declarations

Conflict of interest

The authors declare that they have no known conflict financial interest or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liu, S., Mei, L., Shen, M. et al. Effect of Initial Kinetic Energy of Si3N4 Ball on Impact Wear Behavior of High-Velocity Oxygen Fuel-Sprayed WC-10Co-4Cr Coating and Medium-Carbon Steel. J. of Materi Eng and Perform 32, 7285–7296 (2023). https://doi.org/10.1007/s11665-022-07633-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-07633-3