Abstract

Friction stir processing (FSP) was carried out in AA6063 alloy using the tools with different pin eccentricities (0 and 0.6 mm) under different cooling rates. Results showed that the FSP using a tool with 0.6 mm pin eccentricity enhances the hardness, tensile strength, fretting wear resistance, and corrosion resistance of AA6063 alloy. Moreover, a high cooling rate using a water circulating copper block further enhances the hardness, tensile strength, fretting wear resistance, and corrosion resistance of AA6063 alloy. Pin eccentricity and increasing cooling rate reduce the peak temperature during FSP, thereby preventing grain coarsening, resulting in fine grain structure, enhancing the hardness, tensile strength, fretting wear resistance, and corrosion resistance. The XRD pattern reveals no phase changes due to FSP, but peak broadening occurred in FSP specimens.

Similar content being viewed by others

References

P. Nelaturu, S. Jana, R.S. Mishra, G. Grant and B.E. Carlson, Influence of Friction Stir Processing on the Room Temperature Fatigue Cracking Mechanisms of A356 Aluminum Alloy, Mater. Sci. Eng. A, 2018, 716, p 165–178.

A.K. Srivastava, A.R. Dixit and S. Tiwari, A Review on the Intensification of Metal Matrix Composites and Its Nonconventional Machining, IEEE J. Sel. Top. Quantum Electron., 2018, 25, p 213–228.

C. Srinivasan and M. Karunanithi, Fabrication of Surface Level Cu/SiCp Nanocomposites by Friction Stir Processing Route, J. Nanotechnol., 2015, 2015, p 1–10. https://doi.org/10.1155/2015/612617

S. Sahraeinejad, H. Izadi, M. Haghshenas and A.P. Gerlich, Fabrication of Metal Matrix Composites by Friction Stir Processing with Different Particles and Processing Parameters, Mater. Sci. Eng. A, 2015, 626, p 505–513.

N. Arun Prakash, R. Gnanamoorthy and M. Kamaraj, Fretting Wear Behavior of Fine Grain Structured Aluminium Alloy Formed by Oil Jet Peening Process under Dry Sliding Condition, Wear, 2012, 294–295, p 427–437.

E. Aghaie, J. Stroh, D. Sediako, A. Rashidi and A.S. Milani, Improving the Mechanical Properties of the B319 Aluminum Alloy by Addition of Cerium, Mater. Sci. Eng. A, 2020, 793, p 1398–1399.

P. Gao, J. Li, Z. Yang, Y. Guo and Y. Wang, Preparation of Al/SiC Composite Coatings on Surface of Aluminum Alloy by Atmospheric Plasma Spraying, **you **shu Cailiao Yu Gongcheng/Rare Met. Mater. Eng., 2015, 44, p 2396–2400.

I. Sabirov, M.Y. Murashkin and R.Z. Valiev, Nanostructured Aluminium Alloys Produced by Severe Plastic Deformation: New Horizons in Development, Mater. Sci. Eng. A, 2013, 560, p 1–24.

Z.Y. Ma, Friction Stir Processing Technology: A Review, Metall. Mater. Trans. A Phys. Metall. Mater. Sci., 2008, 39, p 642–658.

H.G. Rana, V.J. Badheka and A. Kumar, Fabrication of Al7075 / B4C Surface Composite by Novel Friction Stir Processing (FSP) and Investigation on Wear Properties, Proc. Technol., 2016, 23, p 519–528.

J.Q. Su, T.W. Nelson and C.J. Sterling, Friction Stir Processing of Large-Area Bulk UFG Aluminum Alloys, Scr. Mater., 2005, 52, p 135–140.

M.W. Mahoney, A.J. Barnes, W.H. Bingel and C.B. Fuller, Superplastic Forming of 7475 Al Sheet After Friction Stir Processing (FSP), Mater. Sci. Forum, 2004, 447–448, p 505–512. https://doi.org/10.4028/www.scientific.net/MSF.447-448.505

Thomas. United States Patent 1992, 19.

W. Zhang, L. Tan, D. Ni, J. Chen, Y.C. Zhao, L. Liu et al., Effect of Grain Refinement and Crystallographic Texture Produced by friction Stir Processing on the Biodegradation Behavior of a Mg-Nd-Zn Alloy, J. Mater. Sci. Technol., 2019, 35, p 777–783.

H.K. Rafi, G.D.J. Ram, G. Phanikumar and K.P. Rao, Microstructural Evolution During Friction Surfacing of Tool Steel H13, Mater. Des., 2011, 32, p 82–87.

N. Saito, I. Shigematsu, T. Komaya, T. Tamaki, G. Yamauchi and M. Nakamura, Grain Refinement of 1050 Aluminum Alloy by Friction Stir Processing, J. Mater. Sci. Lett., 2001, 20, p 1913–1915.

R.S. Mishra and M.W. Mahoney, Friction Stir Processing: A New Grain Refinement Technique to Achieve High Strain Rate Superplasticity in Commercial Alloys, Mater. Sci. Forum, 2001, 357–359, p 507–514. https://doi.org/10.4028/www.scientific.net/MSF.357-359.507

G.K. Padhy, C.S. Wu and S. Gao, Friction Stir Based Welding and Processing Technologies Processes, Parameters, Microstructures and Applications: A Review, J. Mater. Sci. Technol., 2018, 34, p 1–38.

V.V. Patel, V. Badheka and A. Kumar, Influence of Friction Stir Processed Parameters on Superplasticity of Al-Zn-Mg-Cu Alloy, Mater. Manuf. Process, 2016, 31, p 1573–1582.

E.A. El-Danaf, M.M. El-Rayes and M.S. Soliman, Friction Stir Processing: An Effective Technique to Refine Grain Structure and Enhance Ductility, Mater. Des., 2010, 31, p 1231–1236.

E.R.I. Mahmoud, K. Ikeuchi and M. Takahashi, Fabrication of SiC Particle Reinforced Composite on Aluminium Surface by Friction Stir Processing, Sci. Technol. Weld. Join., 2008, 13, p 607–618.

E.R.I. Mahmoud, M. Takahashi, T. Shibayanagi and K. Ikeuchi, Effect of Friction Stir Processing Tool Probe on Fabrication of SiC Particle Reinforced Composite on Aluminium Surface, Sci. Technol. Weld. Join., 2009, 14, p 413–425.

H. Zhao, Q. Pan, Q. Qin, Y. Wu and X. Su, Effect of the Processing Parameters of Friction Stir Processing on the Microstructure and Mechanical Properties of 6063 Aluminum Alloy, Mater. Sci. Eng. A, 2019, 751, p 70–79.

A. Dolatkhah, P. Golbabaei, M.K. Besharati Givi and F. Molaiekiya, Investigating Effects of Process Parameters on Microstructural and Mechanical Properties of Al5052/SiC Metal Matrix Composite Fabricated Via Friction Stir Processing, Mater. Des., 2012, 37, p 458–464.

M.S. Węglowski, M. Kopyściański and S. Dymek, Friction stir Processing Multi-Run Modification of Cast Aluminum Alloy, Key Eng. Mater., 2014, 611–612, p 1595–1600. https://doi.org/10.4028/www.scientific.net/KEM.611-612.1595

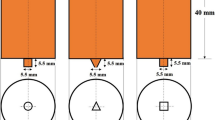

Y. Mao, L. Ke, F. Liu, Q. Liu, C. Huang and L. **ng, Effect of tool Pin Eccentricity on Microstructure and Mechanical Properties in friction Stir Welded 7075 Aluminum Alloy Thick Plate, Mater. Des., 2014, 62, p 334–343.

Y. Chen, H. Wang, X. Wang, H. Ding, J. Zhao, F. Zhang et al., Influence of Tool Pin Eccentricity on Microstructural Evolution and Mechanical Properties of Friction Stir Processed Al-5052 Alloy, Mater. Sci. Eng. A, 2019, 739, p 272–276.

A.R.S. Essa, M.M.Z. Ahmed, A.K.Y.A. Mohamed and A.E. El-Nikhaily, An Analytical Model of Heat Generation for Eccentric Cylindrical Pin in Friction Stir Welding, J. Mater. Res. Technol., 2016, 5, p 234–240.

V. Patel, V. Badheka, W. Li and S. Akkireddy, Hybrid friction Stir Processing with Active Cooling Approach to Enhance Superplastic Behavior of AA7075 Aluminum Alloy, Arch. Civ. Mech. Eng., 2019, 19, p 1368–1380.

L. Fratini, G. Buffa and R. Shivpuri, Mechanical and Metallurgical Effects of in Process Cooling During Friction Stir Welding of AA7075-T6 Butt Joints, Acta Mater., 2010, 58, p 2056–2067.

H. Lin, Y. Wu, S. Liu and X. Zhou, Effect of Cooling Conditions on Microstructure and Mechanical Properties of Friction Stir Welded 7055 Aluminium Alloy Joints, Mater. Charact., 2018, 141, p 74–85.

L. Kruszka, J. Anaszewicz and M. Grazia, Experimental and Numerical Analysis of Al6063 Duralumin Using Taylor Impact Test, EPJ Web Conf., 2012, 26, p 1–4.

K.N. Salloomi, Fully Coupled Thermomechanical Simulation of Friction Stir Welding of Aluminum 6061–T6 Alloy T-joint, J. Manuf. Process., 2019, 45, p 746–754.

S.S.M. Mehrian, M. Rahsepar, F. Khodabakhshi and A.P. Gerlich, Effects of Friction Stir Processing on the Microstructure, Mechanical and Corrosion Behaviors of an Aluminum-Magnesium Alloy, Surf. Coat. Technol., 2021, 405, p 126647.

L. Karthikeyan, V.S. Senthilkumar, V. Balasubramanian and S. Natarajan, Mechanical Property and Microstructural Changes During Friction Stir Processing of Cast Aluminum 2285 Alloy, Mater. Des., 2009, 30, p 2237–2242.

S. Swaminathan, K. Oh-Ishi, A.P. Zhilyaev, C.B. Fuller, B. London, M.W. Mahoney, Peak Stir Zone Temperatures During Friction Stir Processing.

F. Ozturk, A. Sisman, S. Toros, S. Kilic and R.C. Picu, Influence of aging treatment on Mechanical Properties of 6061 Aluminum Alloy, Mater. Des., 2010, 31, p 972–975.

C. Hamilton and M. Stanisław, A simulation of Friction-Stir Processing for Temperature and Material Flow, Metall. Mater. Trans. B, 2015, 46, p 1409–1418.

C. Hamilton, M.S. Węglowski, S. Dymek and P. Sedek, Using a Coupled Thermal/Material Flow Model to Predict Residual Stress in Friction Stir Processed AlMg9Si, J. Mater. Eng. Perform, 2015, 24, p 1305–1312.

M.S. Węglowski, S. Dymek and C.B. Hamilton, Experimental Investigation and Modelling of Friction Stir Processing of Cast Aluminium Alloy AlSi9Mg, Bull. Pol. Acad. Sci. Tech. Sci., 2013, 61, p 894–903.

P. Asadi, R.A. Mahdavinejad and S. Tutunchilar, Simulation and Experimental Investigation of FSP of AZ91 Magnesium Alloy, Mater. Sci. Eng. A, 2011, 528, p 6469–6477.

J.I. Langford and A.J.C. Wilson, Scherrer After Sixty Years: A Survey and Some New Results in the Determination of Crystallite Size, J. Appl. Crystallogr., 1978, 11, p 102–113.

S. Bagherifard, N. Beretta, S. Monti, M. Riccio, M. Bandini and M. Guagliano, On the Fatigue Strength Enhancement of Additive Manufactured AlSi10Mg Parts by Mechanical and Thermal Post-Processing, Mater. Des., 2018, 145, p 28–41.

C.I. Chang, C.J. Lee and J.C. Huang, Relationship Between Grain Size and Zener-Holloman Parameter During Friction Stir Processing in AZ31 Mg Alloys, Scr. Mater., 2004, 51, p 509–514.

T. Morishige, T. Hirata, M. Tsujikawa and K. Higashi, Comprehensive Analysis of Minimum Grain size in Pure Aluminum Using Friction Stir Processing, Mater. Lett., 2010, 64, p 1905–1908.

R. Senthilkumar, M. Prakash, N. Arun and A.A. Jeyakumar, The Effect of the Number of Passes in Friction Stir Processing of Aluminum Alloy (AA6082) and its Failure Analysis, Appl. Surf. Sci., 2019, 491, p 420–431.

X. Feng, H. Liu and J.C. Lippold, Microstructure Characterization of the stir zone of Submerged Friction Stir Processed Aluminum Alloy 2219, Mater. Charact., 2013, 82, p 97–102.

A. Rahbar-kelishami, A. Abdollah-zadeh, M.M. Hadavi, A. Banerji, A. Alpas and A.P. Gerlich, Effects of Friction Stir Processing on Wear Properties of WC-12%Co Sprayed on 52100 Steel, Mater. Des., 2015, 86, p 98–104.

H. Izadi, A. Nolting, C. Munro, D.P. Bishop, K.P. Plucknett and A.P. Gerlich, Friction Stir Processing of Al/SiC Composites Fabricated by Powder Metallurgy, J. Mater. Process. Tech., 2013, 213, p 1900–1907.

H.S. Arora, H. Singh and B.K. Dhindaw, Wear Behaviour of a Mg Alloy Subjected to Friction Stir Processing, Wear, 2013, 303, p 65–77.

J. Qian, J. Li, J. **ong, F. Zhang and X. Lin, In Situ Synthesizing Al 3Ni for Fabrication of Intermetallic-Reinforced Aluminum Alloy Composites by Friction Stir Processing, Mater. Sci. Eng. A, 2012, 550, p 279–285.

Y. Kwon, I. Shigematsu and N. Saito, Mechanical Properties of Fine-Grained Aluminum Alloy Produced by Friction Stir Process, Scr. Mater., 2003, 49, p 785–789.

F. Khodabakhshi, A. Simchi, A.H. Kokabi and A.P. Gerlich, Similar and Dissimilar Friction-Stir Welding of an PM aluminum-Matrix Hybrid Nanocomposite and Commercial Pure Aluminum: Microstructure and Mechanical Properties, Mater. Sci. Eng. A, 2016, 666, p 225–237.

F. Khodabakhshi, H. Ghasemi Yazdabadi, A.H. Kokabi and A. Simchi, Friction Stir Welding of a P/M Al-Al2O3 Nanocomposite: Microstructure and Mechanical Properties, Mater. Sci. Eng. A, 2013, 585, p 222–232.

C. Rajendran, K. Srinivasan, V. Balasubramanian, H. Balaji and P. Selvaraj, Mechanical Properties and Microstructural Characteristics of Friction Stir Welded AA2014-T6 Aluminium Alloy Joints, J. Mech.. Behav. Mater., 2020, 28, p 169–185.

S.A. Alidokht, A. Abdollah-Zadeh, S. Soleymani, T. Saeid and H. Assadi, Evaluation of micRostructure and WEAR BEHAVIOR of Friction Stir Processed Cast Aluminum Alloy, Mater. Charact., 2012, 63, p 90–97.

M. Varenberg, G. Halperin and I. Etsion, Different Aspects of the rOle of Wear Debris in Fretting Wear, Wear, 2002, 252, p 902–910.

K. Surekha, B.S. Murty and K.P. Rao, Microstructural Characterization and Corrosion Behavior of Multipass Friction Stir Processed AA2219 Aluminium Alloy, Surf. Coat. Technol., 2008, 202, p 4057–4068.

M.V.N.V. Satyanarayana, K. Adepu and K. Chauhan, Effect of Overlap** Friction Stir Processing on Microstructure, Mechanical Properties and Corrosion Behavior of AA6061 Alloy, Metals Mater. Int., 2020, 27(9), p 3563–3573. https://doi.org/10.1007/s12540-020-00757-y

S. Kumar, Ultrasonic Assisted Friction Stir Processing of 6063 Aluminum Alloy, Arch. Civ. Mech. Eng., 2016, 16, p 473–484.

M. Patel and J. Murugesan, Fretting Wear and Corrosion Behaviour of an Al–ZrO2/Ni Hybrid Composite Developed by Friction Stir Processing, Trans. Indian Inst. Met., 2022, 75, p 1–10.

M. Bagheri Hariri, S. Gholami Shiri, Y. Yaghoubinezhad and R.M. Mohammadi, The Optimum Combination of Tool Rotation Rate and Traveling Speed for Obtaining the Preferable Corrosion Behavior and Mechanical Properties of Friction Stir Welded AA5052 Aluminum Alloy, Mater. Des., 2013, 50, p 620–634.

M. Barati, M. Abbasi and M. Abedini, The Effects of Friction Stir Processing and Friction Stir Vibration Processing on Mechanical, Wear and Corrosion Characteristics of Al6061/SiO2 Surface Composite, J. Manuf. Process, 2019, 45, p 491–497.

K.D. Ralston, D. Fabijanic and N. Birbilis, Effect of Grain Size on Corrosion of High Purity Aluminium, Electrochim. Acta, 2011, 56, p 1729–1736.

Acknowledgment

The authors would like to acknowledge SERB (Government of India) for financial assistance through project FILENO.SRG/2019/002353.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Patel, M., Murugesan, J. Effect of the Tool Pin Eccentricity and Cooling Rate on Microstructure, Mechanical Properties, Fretting Wear, and Corrosion Behavior of Friction Stir Processed AA6063 Alloy. J. of Materi Eng and Perform 31, 8554–8566 (2022). https://doi.org/10.1007/s11665-022-06860-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-06860-y