Abstract

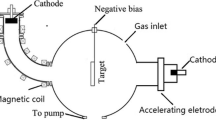

To investigate the effects of Cr do** on the microstructure and tribological properties of multi-layered diamond-like carbon (DLC) films, Cr-DLC films with Cr contents ranging from 0 to 22 at.% were deposited on 0Cr19Ni10 stainless steel and Si wafer surfaces by unbalanced magnetron sputtering. The thickness of the transition layer is 180 nm and the Cr-DLC film ranging from 1.3 to 1.5 µm. The microstructure, mechanical and tribological properties of the films were systematically investigated at room temperature in atmospheric environment. Results show that increasing the Cr target current can effectively improve the incident particle density and reduce surface roughness. As a strong carbon metal, Cr has significant influence on the structure and properties of the film for bonding with carbon atoms during deposition. High-energy Cr particles are favorable for films to increase the sp3 hybrid bond ratio and reduce internal stress. The high-hardness sp3 hybrid phase, Cr carbide, oxide dispersion can effectively improve the mechanical properties of the film, but overdo** is detrimental for mechanical properties of the film. The internal stress shows a continuous trend of decreasing with the increasing Cr content and it reduced up to 80% compared with pure DLC films. The films prepared with Cr sputtering current of 0.4 A demonstrate the best tribological properties, and the friction coefficient and wear rate are 0.15 and 2.9 × 10−7 mm3/Nm, respectively.

Similar content being viewed by others

References

X. Xu, J. Qin, and Z. Li, Research Advances of Graphene, Prog. Chem., 2009, 21(12), p 2559–2567

L. Bai, G. Zhang, Z. Lu, Z. Wu, Y. Wang, L. Wang, and P. Yan, Tribological Mechanism of Hydrogenated Amorphous Carbon Film Against Pairs: A Physical Description, J. Appl. Phys., 2011, 110(3), p 6140–6748

Ö.D. Coşkun and T. Zerrin, Optical, Structural and Bonding Properties of Diamond-Like Amorphous Carbon Films Deposited by DC Magnetron Sputtering, Diam. Relat. Mater., 2015, 56, p 29–35

P. Mahtani, K.R. Leong, I. **ao, A. Chutinan, N.P. Kherani, and S. Zukotynski, Diamond-Like Carbon Based Low-Emissive Coatings, Sol. Energy Mater. Sol. Cells, 2011, 95(7), p 1630–1637

S.C.H. Kwok, W. Zhang, G.J. Wan, D.R. McKenzie, M.M.M. Bilek, and P.K. Chu, Hemocompatibility and Anti-Bacterial Properties of Silver Doped Diamond-Like Carbon Prepared by Pulsed Filtered Cathodic Vacuum Arc Deposition, Diam. Relat. Mater., 2007, 16(4–7), p 1353–1360

D. Fu, D. **e, C.H. Zhang, C. Zhang, and L. Liu, Preparation and Characteristics of Nanoscale Diamond-Like Carbon Films for Resistive Memory Applications, Chin. Phys. Lett., 2010, 27(9), p 225–228

B.Y. Zhang, Q.U. Yan-Qing, H.M. **e, and C.Y. Nie, Review of Preparation and Application of Diamond-Like Carbon Films, Surf. Technol., 2007, 36(3), p 70–73

A.A. Voevodin, J.M. Schneider, C. Rebholz, and A. Matthews, Multilayer Composite Ceramicmetal-DLC Coatings for Sliding Wear Applications, Tribol. Int., 1996, 29(7), p 559–570

F.J. Li, S. Zhang, J. Kong, Y. Zhang, and W. Zhang, Multilayer DLC Coatings Via Alternating Bias During Magnetron Sputtering, Thin Solid Films, 2011, 519(15), p 4910–4916

X. Sui, J. Liu, S. Zhang, J. Yang, and J. Hao, Microstructure, Mechanical and Tribological Characterization of CrN/DLC/Cr-DLC Multilayer Coating with Improved Adhesive Wear Resistance, Appl. Surf. Sci., 2018, 439, p 24–32

J.Y. Jao, S. Han, L.S. Chang, Y.-C. Chen, C.-L. Chang, and H.C. Shih, Formation and Characterization of DLC:Cr: Cu Multi-layers Coating Using Cathodic Arc Evaporation, Diam. Relat. Mater., 2009, 18(2–3), p 368–373

Y.J. Jo, T.F. Zhang, M.J. Son, and K.H. Kim, Synthesis and Electrochemical Properties of Ti-Doped DLC Films by a Hybrid PVD/PECVD Process, Appl. Surf. Sci., 2018, 433, p 1184–1191

M. Goto, Preparations and Tribological Properties of Soft-Metal/DLC Composite Coatings by RF Magnetron Sputter Using Composite Targets, Int. J. Mech. Mater. Des., 2018, 14(3), p 313–327

F.M. Wang, M.W. Chen, and Q.B. Lai, Metallic Contacts to Nitrogen and Boron Doped Diamond-Like Carbon Films, Thin Solid Films, 2010, 518(12), p 3332–3336

S. Shen, J. Chen, X. Wang, L. Zhao, and L. Guo, Microwave-Assisted Hydrothermal Synthesis of Transition-Metal Doped ZnIn2S4 and Its Photocatalytic Activity for Hydrogen Evolution Under Visible Light, J. Power Sour., 2011, 196(23), p 10112–10119

R. Fernandes, N. Patel, A. Miotello, R. Jaiswal, and D.C. Kothari, Dehydrogenation of Ammonia Borane with Transition Metal-Doped Co-B Alloy Catalysts, Int. J. Hydrog. Energy, 2012, 37(3), p 2397–2406

N. Boubiche, J. El Hamouchi, J. Hulik, M. Abdesslam, C. Speisser, F. Djeffal, and F. Le Normand, Kinetics of Graphitization of Thin Diamond-Like Carbon (DLC) Films Catalyzed by Transition Metal, Diam. Relat. Mater., 2019, 91, p 190–198

W. Dai and A. Wang, Synthesis, Characterization and Properties of the DLC Films with Low Cr Concentration Do** by a Hybrid Linear Ion Beam System, Surf. Coat. Technol., 2011, 205(8–9), p 2882–2886

L. Yang, A. Neville, A. Brown, P. Ransom, and A. Morina, Friction Reduction Mechanisms in Boundary Lubricated W-Doped DLC Coatings, Tribol. Int., 2014, 70, p 26–33

X.S. Tang, H.J. Wang, L. Feng, L.X. Shao, and C.W. Zou, Mo Doped DLC Nanocomposite Coatings with Improved Mechanical and Blood Compatibility Properties, Appl. Surf. Sci., 2014, 311, p 758–762

M. Masuko, T. Ono, S. Aoki, A. Suzuki, and H. Ito, Friction and Wear Characteristics of DLC Coatings with Different Hydrogen Content Lubricated with Several Mo-containing Compounds and Their Related Compounds, Tribol. Int., 2015, 82, p 350–357

J.F.R. Robertson, Diamond-Like Amorphous Carbon, Mater. Sci. Eng. R Rep., 2002, 37(4–6), p 129–281

C. Donnet and A. Erdemir, Historical Developments and New Trends in Tribological and Solid Lubricant Coatings, Surf. Coat. Technol., 2004, 180-181(3), p 76–84

K. Holmberg, H. Ronkainen, A. Laukkanen, and K. Wallin, Friction and Wear of Coated Surfaces-Scales, Modelling and Simulation of Tribomechanisms, Surf. Coat. Technol., 2007, 202(4), p 1034–1049

L. Bai, N. Srikanth, H. Wu, Y. Liu, B. Liu, and K. Zhou, Investigation on Tensile Behaviors of Diamond-Like Carbon Films, J. Non-Cryst. Solids, 2016, 443, p 8–16

N. Dwivedi, S. Kumar, H.K. Malik, C. Sreekumar, S. Dayal, C.M.S. Rauthan, and O.S. Panwar, Investigation of Properties of Cu Containing DLC Films Produced by PECVD Process, J. Phys. Chem. Solids, 2012, 73(2), p 308–316

F.R. Marciano, L.F. Bonetti, L.V. Santos, N.S. Da-Silva, E.J. Corat, and V.J. Trava-Airoldi, Antibacterial Activity of DLC and Ag-DLC Films Produced by PECVD Technique, Diam. Relat. Mater., 2009, 18(5-8), p 1010–1014

Y. Wu, J. Chen, H. Li, L. Ji, Y. Ye, and H. Zhou, Preparation and Properties of Ag/DLC Nanocomposite Films Fabricated by Unbalanced Magnetron Sputtering, Appl. Surf. Sci., 2013, 284(11), p 165–170

X. Yu, M. Hua, and C. Wang, Influence of Ag Content and Nanograin Size on Microstructure, Mechanical and Sliding Tribological Behaviors of Ag-DLC Films, J. Nanosci. Nanotechnol., 2009, 9(11), p 6366–6371

R. Paul, R. Bhar, and A.K. Pal, Field Emission Properties of Composite Nano-Au/DLC Films Prepared by CVD Technique, Mater. Res. Bull., 2010, 45(5), p 576–583

M. Guozheng, X. Binshi, W. Haidou, C. Shuying, and X. Zhiguo, Excellent Vacuum Tribological Properties of Pb/PbS Film Deposited by RF Magnetron Sputtering and Ion Sulfurizing, ACS Appl. Mater. Interfaces., 2014, 6(1), p 532–538

W. Zhai, N. Srikanth, L.B. Kong, and K. Zhou, Carbon Nanomaterials in Tribology, Carbon, 2017, 119, p 150–171

J.A. Santiago, I. Fernández-Martínez, J.C. Sánchez-López, T.C. Rojas, A. Wennberg, V. Bellido-González, J.M. Molina-Aldareguia, M.A. Monclús, and R. González-Arrabal, Tribomechanical Properties of Hard Cr-Doped DLC Coatings Deposited by Low-Frequency HiPIMS, Surf. Coat. Technol., 2020, 382, p 124899. https://doi.org/10.1016/j.surfcoat.2019.124899

M. Yan, X. Wang, S. Zhang, S. Zhang, X. Sui, W. Li, J. Hao, and W. Liu, Friction and wear properties of GLC and DLC coatings under ionic liquid lubrication, Tribol. Int., 2020, 143, p 106067

J. Wu, G. Wu, X. Kou, Z. Lu, and G. Zhang, Tribological Properties of Amorphous Carbon in Hydrochloric Acid with ta-C Counterpart, Surf. Coat. Technol., 2019, 380, p 125004

L. Tang, J. Kang, P. He, S. Ding, S. Chen, M. Liu, Y. **ong, G. Ma, and H. Wang, Effects of Spraying Conditions on the Microstructure and Properties of NiCrBSi Coatings Prepared by Internal Rotating Plasma Spraying, Surf. Coat. Technol., 2019, 374, p 625–633

L. Fayette, B. Marcus, and M. Mermoux, Local Order in CVD Diamond Films: Comparative Raman, x-ray-diffraction, and x-ray-absorption Near-Edge Studies, Phys. Rev. B, 1998, 57, p 14123–14132

S. Neuville, Quantum Electronic Mechanisms of Atomic Rearrangements During Growth of Hard Carbon Films, Surf. Coat. Technol., 2011, 206(4), p 703–726

K.K. Mishra, R. Rani, N. Kumar, T.R. Ravindran, K.J. Sankaran, and I.N. Lin, High Pressure Raman Spectroscopic Studies on Ultrananocrystalline Diamond Thin Films: Anharmonicity and Thermal Properties of the Grain Boundary, Diam. Relat. Mater., 2017, 80, p 45–53

A. Ferrari, Carlo, Determination of Bonding in Diamond-Like Carbon by Raman Spectroscopy, Diam. Relat. Mater., 2002, 11(3–6), p 1053–1061

A.C. Ferrari, B. Kleinsorge, N.A. Morrison, A. Hart, V. Stolojan, and J. Robertson, Stress Reduction and Bond Stability During Thermal Annealing of Tetrahedral Amorphous Carbon, J. Appl. Phys., 1999, 85(10), p 7190–7191

L. Tang, P. He, J. Kang, L. Wang, S. Ding, S. Chen, X. Zhu, F. **e, L. Zhou, G. Ma, and H. Wang, Significantly Enhanced Mechanical and Tribological Properties of Co-Based Alloy Coatings by Annealing Treatment, Tribol. Int., 2020, 146, p 106265. https://doi.org/10.1016/j.triboint.2020.106265

C. Zou, H.J. Wang, L. Feng, and S.W. Xue, Effects of Cr Concentrations on the Microstructure, Hardness, and Temperature-Dependent Tribological Properties of Cr-DLC Coatings, Appl. Surf. Sci., 2013, 286, p 137–141

J.H. Choi, H.S. Ahn, S.C. Lee, and K.R. Lee, Stress Reduction Behavior in Metal-Incorporated Amorphous Carbon Films: First-Principles Approach, J. Phys: Conf. Ser., 2006, 29, p 155–158

C. Casiraghi, A.C. Ferrari, R. Ohr, A.J. Flewitt, and J. Robertson, Dynamic Roughening of Tetrahedral Amorphous Carbon, Phys. Rev. Lett., 2003, 91(22), p 226104

Z. Piao, Z. Zhou, J. Xu, and H. Wang, Use of x-ray Computed Tomography to Investigate Rolling Contact Cracks in Plasma Sprayed Fe-Cr-B-Si Coating, Tribol. Lett., 2018, 67(1), p 11

Acknowledgments

The authors acknowledge financial support by National Natural Science Foundation of China (51675531, 51535011, 51605451), the Pre-Research Program in National 13th Five-Year Plan (61409230603, 61409220205), and Joint Fund of Ministry of Education for Pre-research of Equipment for Young Personnel Project (6141A02033120).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhu, Ln., Li, Jc., Kang, Jj. et al. Different Cr Contents on the Microstructure and Tribomechanical Properties of Multi-Layered Diamond-Like Carbon Films Prepared by Unbalanced Magnetron Sputtering. J. of Materi Eng and Perform 29, 7131–7140 (2020). https://doi.org/10.1007/s11665-020-05198-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-05198-7