Abstract

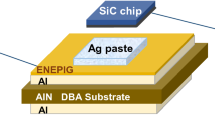

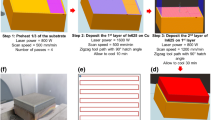

A computational material design approach is applied to propose a novel ceramic material for direct-bonded copper (DBC) substrate with enhanced thermal and structural performance. The material design inherently consists of many competing requirements that require careful decisions regarding key trade-offs in terms of material composition, inclusion size, shape, and distribution to achieve the target properties. The alumina-silicon (Al2O3-SiC) composite, as compared to commercial alumina, used in DBC is found to be the most suitable design among other candidates with improved thermal and structural properties. In order to study the performance characteristics and the effects of the new ceramic composite with improved properties in terms of structural behavior and fatigue life of the DBC substrate, the normal working and extreme thermal cycling conditions were simulated and analyzed using finite element method. The temperature, strain, and localized stress distribution within the substrate at a steady-state condition were analyzed, and the improved Coffin–Manson law was used to calculate the fatigue life of the substrate under extreme thermal cycling conditions. The proposed Al2O3-SiC composite is found to be more robust than the commercial alumina as DBC substrates considering the thermal–mechanical performance. The fatigue life cycle of the DBC substrate with the proposed material is predicted to be about two times longer than the commercial alumina DBC ceramic under transient thermal cycling test.

Similar content being viewed by others

References

Y.S. Sun and J.C. Driscoll, A New Hybrid Power Technique Utilizing a Direct Copper to Ceramic Bond, IEEE Trans. Electron Devices, 1976, 23(8), p 961–967

J.F. Burgess, C.A. Neugebauer, G. Flanagan, and R.E. Moore, The Direct Bonding of Metals to Ceramics and Application in Electronics, Electrocompon. Sci. Technol., 1976, 2(4), p 233–240

J. Schulz-Harder, Advantages and New Development of Direct Bonded Copper Substrates, Microelectronics Reliability, 2003, 43, p 359–365

G. Dong, X. Chen, X. Zhang, K.D.T. Ngo, and G.-Q. Lu, Thermal Fatigue Behaviour of Al2O3-DBC Substrates under High Temperature Cyclic Loading, Solder. Surf. Mt. Technol., 2010, 22(2), p 43–48. https://doi.org/10.1108/09540911011036280

Y. Liu, Power Electronic Packaging, Springer, New York, 2012, https://doi.org/10.1007/978-1-4614-1053-9

Y. Mei, G.Q. Lu, X. Chen, C. Gang, S. Luo, and D. Ibitayo, Investigation of Post-Etch Copper Residue on Direct Bonded Copper (DBC) Substrates, J. Electron. Mater., 2011, 40(10), p 2119–2125

J. Schulz-Harder and K. Exel, Recent Developments of Direct Bonded Copper (DBC) Substrates for Power Modules, in Fifth International Conference on Electronic Packaging Technology Proceedings, 2003. ICEPT2003 (2003)

H. He, R. Fu, D. Wang, X. Song, and M. **g, A New Method for Preparation of Direct Bonding Copper Substrate on Al2O3, Mater. Lett., 2007, 61(19–20), p 4131–4133

K. Hromadka, J. Stulik, J. Reboun, and A. Hamacek, DBC Technology for Low Cost Power Electronic Substrate Manufacturing, Proc. Eng., 2014, 69, p 1180–1183

J. Schulz-Harder, DBC Substrates as a Base for Power MCM’s, in Proceedings of 3rd Electronics Packaging Technology Conference (EPTC 2000) (Cat. No.00EX456), 2000, pp. 315–320

A. Dehmel, J. Schulz-Harder, A. Roth, I. Baumeister, Direct Copper Bonded Ceramic Substrates for Use with Power LEDS, in Proceedings of the Electronic Packaging Technology Conference, EPTC, 2007, p 3–8

J. Park, M. Kim, and A. Roth, Improved Thermal Cycling Reliability of ZTA (Zirconia Toughened Alumina) DBC Substrates by Manipulating Metallization Properties, in 2014 8th International Conference on Integrated Power Systems (CIPS), VDE, 2014

M. Entezarian and R.A.L. Drew, Direct Bonding of Copper to Aluminum Nitride, Mater. Sci. Eng. A, 1996, 212(2), p 206–212

Y. Yoshino, Role of Oxygen in Bonding Copper to Alumina, J. Am. Ceram. Soc., 1989, 72, p 1322–1327

J. Lutz, T. Herrmann, M. Feller, R. Bayerer, T. Licht, and R. Amro, Power Cycling Induced Failure Mechanisms in the Viewpoint of Rough Temperature Environment, in 6th International Conference on Integration of Power Electronics Systems, 2008, pp. 224–237

Y. Wei and J.W. Hutchinson, Nonlinear Delamination Mechanics for Thin Films, J. Mech. Phys. Solids, 1997, 45, p 1137–1159

S. Pietranico, S. Pommier, S. Lefebvre, Z. Khatir, and S. Bontemps, Microelectronics Reliability Characterisation of Power Modules Ceramic Substrates for Reliability Aspects, Microelectron. Reliab. Elsevier Ltd, 2009, 49(9–11), p 1260–1266

S. Pietranico, S. Pommier, S. Lefebvre, and S. Pattofatto, Thermal Fatigue and Failure of Electronic Power Device Substrates, Int. J. Fatigue Elsevier Ltd, 2009, 31(11–12), p 1911–1920

V. Smet, F. Forest, J. Huselstein, F. Richardeau, Z. Khatir, S. Lefebvre, and M. Berkani, Ageing and Failure Modes of IGBT Modules in High Temperature Power Cycling, IEEE Trans. Ind. Electron., 2011, 58(10), p 4931–4941

P. McCluskey, Reliability of Power Electronics under Thermal Loading, in 7th International Conference on Integrated Power Electronics Systems, 2012, pp. 1–8

L. Xu, Y. Zhou, and S. Liu, DBC Substrate in Si- and SiC-Based Power Electronics Modules: Design, Fabrication and Failure Analysis, in 2013 IEEE 63rd Electronic Components and Technology Conference, 2013, 1(2), pp. 1341–1345

K. Shimada, J. Komotori, and M. Shimizu, The Applicability of the Manson-Coffin Law and Miner’s Law to Extremely Low Cycle Fatigue, Trans. Jpn. Soc. Mech. Eng., 1987, 53(491), p 1178–1185

L. Xue, A Unified Expression for Low Cycle Fatigue and Extremely Low Cycle Fatigue and Its Implication for Monotonic Loading, Int. J. Fatigue, 2008, 30, p 1691–1698

L. Xu, M. Wang, Y. Zhou, Z. Qian, and S. Liu, An Optimal Structural Design to Improve the Reliability of Al2O3-DBC Substrates Under Thermal Cycling, Microelectron. Reliab., 2016, 56, p 101–108

G. Dong, G. Lei, X. Chen, K. Ngo, and G.-Q. Lu, Edge Tail Length Effect on Reliability of DBC Substrates under Thermal Cycling, Solder. Surf. Mt. Technol., 2009, 21(3), p 10–15

C. Van Godbold, V.A. Sankaran, and J.L. Hudgins, Thermal Analysis of High-Power Modules, IEEE Trans. Power Electron., 1997, 12(1), p 3–11

S.S. Akhtar, L.T. Kareem, A.F.M. Arif, M.U. Siddiqui, and A.S. Hakeem, Development of a Ceramic-Based Composite for Direct Bonded Copper Substrate, Ceram. Int., 2017, 43(6), p 5236–5246

Y. Liu, Power Electronic Packaging: Design, Assembly Process, Reliability and Modeling, Springer, 2012

JEDEC Solid State Technology Association, JEDEC Standard JESD22-A104D, Temperature Cycling, Jedec.Org, 2009, (May 2005), p. 11

Matweb.com, MatWeb, Material Property Data (2015)

E.M. Dede, J. Lee, and T. Nomura, Multiphysics Simulation, Springer, London, 2014, https://doi.org/10.1007/978-1-4471-5640-6

N. Zhu, Planar Metallization Failure Modes in Integrated Power Electronics Modules. Faculty of the Virginia Polytechnic Institute and State University, 2006, https://vtechworks.lib.vt.edu/bitstream/handle/10919/27530/NingZhuETDMay10.pdf?sequence=1

Acknowledgments

The authors would like to acknowledge the support of King Fahd University of Petroleum and Minerals for funding this work through project FT141009.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Akhtar, S.S., Lemboye, K.T., Arif, A.F.M. et al. Design and Performance Evaluation of Al2O3-SiC Composite for Direct-Bonded Copper Substrate. J. of Materi Eng and Perform 27, 5831–5844 (2018). https://doi.org/10.1007/s11665-018-3702-2

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3702-2