Abstract

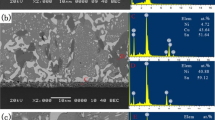

The use of Ga as a micro-alloying element in Sn-based solders can change the microstructure of solder joints to improve the mechanical properties, and even suppress the interfacial intermetallic compound (IMC) growth. This research investigated the effects of Ga addition (0.2–1 wt.%Ga) on the IMC formation and morphological evolution in the Sn-based solder joints with Ni substrate. In the soldering reaction at 250°C and with less than 0.2 wt.%Ga addition, the formed phase was Ni3Sn4. When the Ga addition increased to 0.5 wt.%, it changed to a thin Ni2Ga3 layer of ∼1 μm thick, which stably existed at the interface in the initial 1-h reaction. Subsequently, the whole Ni2Ga3 layer detached from the Ni substrate and drifted into the molten solder. The Ni3Sn4 phase became dominant in the later stage. Notably, the Ga addition significantly reduced the grain size of Ni3Sn4, resulting in the massive spalling of Ni3Sn4 grains. With 1 wt.%Ga addition, the Ni2Ga3 layer remained very thin with no significant growth, and it stably existed at the interface for more than 10 h. In addition, the solid-state reactions were examined at temperatures of 160°C to 200°C. With addition of 0.5 wt.%Ga, the Ni3Sn4 phase dominated the whole reaction. By contrast, with increasing to 1 wt.%Ga, only a thin Ni2Ga3 layer was found even after aging at 160°C for more than 1200 h. The 1 wt.%Ga addition in solder can effectively inhibit the Ni3Sn4 formation in soldering and the long-term aging process.

Similar content being viewed by others

References

K.-W. Moon, W.J. Boettinger, U.R. Kattner, F.S. Biancaniello, and C.A. Handwerker, J. Electron. Mater. 29, 1122 (2000).

M.N. Islam, Y.C. Chan, M.J. Rizvi, and W. Jillek, J. Alloys Compd. 400, 136 (2005).

C.E. Ho, S.Y. Yang, and C.R. Kao, J. Mater. Sci. 18, 155 (2007).

J.-W. Yoon, S.-W. Kim, and S.-B. Jung, J. Alloys Compd. 392, 247 (2005).

N. Hamada, T. Uesugi, Y. Takigawa, and K. Higashi, J. Alloys Compd. 527, 226 (2012).

C.-M. Chuang and K.-L. Lin, J. Electron. Mater. 32, 1426 (2003).

B. Li, Y. Shi, Y. Lei, F. Guo, Z. **a, and B. Zong, J. Electron. Mater. 34, 217 (2005).

A.A. EI-Daly, A.M. EI-Taher, and T.R. Dalloul, J. Alloys Compd. 587, 32 (2014).

Q.K. Zhang, W.M. Long, X.Q. Yu, Y.Y. Pei, and P.X. Qiao, J. Alloys Compd. 622, 973 (2015).

N.-S. Liu and K.-L. Lin, Scr. Mater. 54, 219 (2006).

C.-H. Wang and H.-T. Shen, Intermetallics 18, 616 (2010).

C.-F. Tseng and J.-G. Duh, Mater. Sci. Eng. A 580, 169 (2013).

C.C. Li, J.-H. Ke, C.A. Yang, and C.R. Kao, Mater. Lett. 156, 150 (2015).

S.-W. Chen and C.-H. Wang, J. Mater. Res. 21, 2270 (2006).

C.-H. Wang, H.-H. Chen, and W.-H. Lai, J. Electron. Mater. 40, 2436 (2011).

C.-H. Wang, P.-Y. Li, and K.-T. Li, Intermetallics 59, 68 (2015).

S.-K. Lin, T.L. Nguyen, S.-C. Wu, and Y.-H. Wang, J. Alloys Compd. 586, 319 (2014).

C.-H. Wang and K.-T. Li, J. Alloys Compd. 649, 1197 (2015).

C.-H. Wang, K.-T. Li, and C.-Y. Lin, Intermetallics 67, 102 (2015).

Q.K. Zhang, W.M. Long, X.Q. Yu, Y.Y. Pei, and P.X. Qiao, J. Alloys Compd. 622, 973 (2015).

W.X. Yuan, Z.Y. Qiao, H. Ipser, and G. Eriksson, J. Phase Equilib. Diffus. 25, 68 (2004).

K.P. Gupta, J. Phase Equilib. Diffus. 29, 374 (2008).

C.-H. Wang and S.-W. Chen, Acta Mater. 54, 247 (2006).

Acknowledgements

This research was supported by the Ministry of Science and Technology of Taiwan under Project No. MOST 104-2221-E-194-062-MY2.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, CH., Li, KT. Effects of Ga Addition on Interfacial Reactions Between Sn-Based Solders and Ni. J. Electron. Mater. 45, 6200–6207 (2016). https://doi.org/10.1007/s11664-016-4763-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-016-4763-3