Abstract

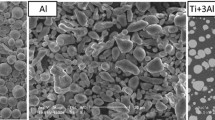

Titanium metal preparation from titanium dioxide (TiO2) has been the subject of numerous studies to overcome the chlorination processes at the heart of the Kroll process. In this study, an alumino-magnesiothermic reduction approach is employed to obtain a Ti-rich ingot via the combustion of an exothermic mixture of TiO2–KClO4–Al(Mg)-KClO4–CaF2 composition in argon. The combustion temperatures are measured, and the reaction patches are highlighted. The synthesis conditions of the Ti-rich ingot were carefully examined depending on the Al particle size, Al/Mg ratio, TiO2 precursor type, and CaF2 concentration. XRD analysis states that the ingot obtained under optimized experimental conditions is single-phase Ti metal. ICP-MS analysis revealed residual Al and O in the Ti ingot with 3.5 and 4.0 wt pct content, respectively.

Graphical abstract

Similar content being viewed by others

References

W. Kroll: Trans. Electrochem. Soc., 1940, vol. 78, pp. 35–47.

H.H. Nersisyan, H.I. Won, C.W. Won, A. Jo, and J.H. Kim: Chem. Eng. J., 2014, vol. 235, pp. 67–74.

C.W. Won, H.H. Nersisyan, and H.I. Won: Chem. Eng. J., 2010, vol. 157, pp. 270–75.

H.H. Nersisyan, J.H. Lee, J.R. Ding, K.S. Kim, K.V. Manukyan, and A.S. Mukasyan: Prog. Energy Combust. Sci., 2017, vol. 63, pp. 79–118.

K. Choi, H. Choi, and I. Son: Metall. Mater. Trans. B, 2017, vol. 48B, pp. 922–32.

R. Bolivar and B. Friedrich: Proc. EMS, Germany, 2009, pp. 1–17.

J.P. Coughlin: Mines Bull., 1954, vol. 542, pp. 14–28.

R.O. Suzuki and S. Inoue: Metall. Mater. Trans. B, 2003, vol. 34B, pp. 277–85.

A.D. Mah, K.K. Kelley, N.L. Gellert, E.G. King, and C.J. O’Brien: Thermodynamic Properties of Titanium-Oxygen Solutions and Compounds, Bureau of Mines, 1955.

Y. **a, H.D. Lefler, Y. Zhang, P. Sun, and Z.Z. Fang: Extractive Metallurgy of Titanium, Elsevier, 2020, pp. 165–79.

H. Lefler, Z.Z. Fang, Y. Zhang, P. Sun, and Y. **a: Metall. Mater. Trans. B, 2018, vol. 49B, pp. 2998–3006.

Z.Z. Fang, Y. Zhang, H. Lefler, T. Zhang, P. Sun, and Z. Huang: Mater. Trans., 2017, vol. 58, pp. 355–60.

Z.Z. Fang, S. Middlemas, J. Guo, and P. Fen: J. Am. Chem. Soc., 2013, vol. 135, pp. 18248–51.

R.C. West: Handbook of Chemistry and Physics, 68th ed., CRC Press, Boca Raton, FL, 1987–1988.

F.H. Froes: JOM, 1998, vol. 50, pp. 41–43.

R.O. Suzuki: JOM, 2007, vol. 59, pp. 68–71.

T.H. Okabe, T. Uda, E. Kasai, and Y. Waseda: Proc. TMS, 1997, pp. 133–51.

T.H. Okabe, T. Oda, and Y. Mitsuda: J. Alloys Compd., 2004, vol. 364, pp. 156–63.

H.H. Nersisyan, S.C. Kwon, V. Ri, Y.J. Lee, and B.U. Yoo: J. Solid State Chem., 2018, vol. 267, pp. 13–21.

J.H. Lee, H. Nersisyan, K.S. Lim, W.B. Kim, and W.S. Choi: Metall. Mater. Trans. B, 2021, vol. 52B, pp. 412–22.

A.A. Shiryaev: Int. J. SHS, 1995, vol. 4, pp. 351–62.

R. Mola and A. Dziadon: Arch. Foundry Eng., 2008, vol. 8, pp. 127–32.

L. Kjellqvist, P. Mason, Q. Chen, and K. Wu: Proc. TMS (Liq. Met. Process. Cast.), 2013, pp. 21–28.

Acknowledgments

This work was supported by the Industrial Strategic Technology Development Program (20010585, High Purity Metal Refining Technology for Titanium Metal with Zero Toxic Gas Emission) funded by the Ministry of Trade, Industry and Energy (MOTIE, Korea).

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lee, J.H., Nersisyan, H., Huynh, TN. et al. Combustion-Alumino-Magnesiothermic Reduction of TiO2 to Produce a Ti-Rich Ingot. Metall Mater Trans B 53, 3147–3158 (2022). https://doi.org/10.1007/s11663-022-02594-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-022-02594-3