Abstract

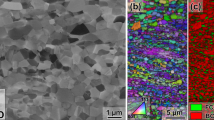

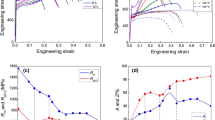

In this paper, the tensile properties, texture evolution, and deformation anisotropy of a cold-rolled Fe−0.3C–6.86Mn–3.5Al steel during superplastic deformation at 650 °C–750 °C and 0.25 × 10−3 s−1− 4 × 10−3 s−1 were studied. In particular, under 750 °C and 1 × 10−3 s−1, the anisotropic microstructure evolution and texture characteristics were measured using EBSD. The results indicate that Medium Mn steel (MMS) sheets exhibit significant anisotropy under high tensile stress. The transverse direction (TD) specimens exhibit the highest peak strength of 145 MPa, and rolling direction (RD) specimens exhibit the highest elongation of 1295 pct. The plastic anisotropy r value of the RD sample varied more significantly than that of the TD sample. When the RD sample fractures, the aspect ratio reaches its minimum value (1.52), and ellipse fitting angle (θ) distributes from 0 to 90 degree and from 180 to 90 degree, which indicates that a large number of grains have undergone rotation.

Similar content being viewed by others

Data Availability

All data in this study are available from the corresponding author by request.

References

S.S. Li and H.W. Luo: Int. J. Miner. Met. Mater., 2021, vol. 28, pp. 741–53.

H.J. Pan, P. Jiang, Y. Zhang, W.P. Wu, Z.Z. Wang, Q. Wang, and H.Y. Li: Mater. Sci. Eng. A, 2021, vol. 802, p. 140680.

O. Bouaziz, H. Zurob, and M.X. Huang: Steel Res. Int., 2013, vol. 84, pp. 937–47.

B. Chongthairungruang, V. Uthaisangsuk, S. Suranuntchai, and S. Jirathearanat: Mater. Des., 2012, vol. 39, pp. 318–28.

J.Y. Lee, M. Kim, and Y.L. Lee: Mater. Sci. Eng. A, 2022, vol. 843, p. 143148.

S.B. Bai, W.T. **ao, W.Q. Niu, D.Z. Li, and W. Liang: Materials, 2021, vol. 14, p. 2233.

K. Mori, K. Akita, and Y. Abe: Int. J. Mach. Tools Manuf, 2007, vol. 47, pp. 321–25.

J. Wongsa-Ngam and T.G. Langdon: Metals, 2022, vol. 12, p. 1921.

J. Han, S.H. Kang, S.J. Lee, M. Kawasaki, H.J. Lee, D. Ponge, D. Raabe, and Y.K. Lee: Nat. Commun., 2017, vol. 8, p. 751.

S.H. Kang, S.W. Choi, Y.D. Im, and Y.K. Lee: Mater. Sci. Eng. A, 2020, vol. 780, p. 139174.

S.H. Kang, H.B. Jeong, J.S. Hong, and Y.K. Lee: Mater. Sci. Eng. A, 2021, vol. 822, p. 141697.

W.Q. Cao, C.X. Huang, C. Wang, H. Dong, and Y.Q. Weng: Sci. Rep., 2017, vol. 7, p. 9199.

Z.X. Cao, G.L. Wu, X.J. Sun, C. Wang, D. Ponge, and W.Q. Cao: Scr. Mater., 2018, vol. 152, pp. 27–30.

R. Song, D. Ponge, D. Raabe, and R. Kaspar: Acta Mater., 2005, vol. 53, pp. 845–58.

H. Zhang, B. Bai, and D. Raabe: Acta Mater., 2011, vol. 59, pp. 5787–802.

H. Zhang, K.G. Pradeep, S. Mandal, D. Ponge, P. Choi, C.C. Tasan, and D. Raabe: Acta Mater., 2014, vol. 63, pp. 232–44.

H.B. Jeong, S.W. Choi, S.H. Kang, and Y.K. Lee: Mater. Sci. Eng. A, 2022, vol. 848, p. 143408.

H.B. Jeong, J.Y. Lee, J.C. **, H.J. Cho, and Y.K. Lee: J. Alloy. Compd., 2023, vol. 958, p. 170536.

H.J. Cho, H.B. Jeong, J.Y. Lee, and Y.K. Lee: J. Mater. Res. Technol., 2023, vol. 27, pp. 7905–16.

R.B. Figueiredo, M. Kawasaki, and T.G. Langdon: Prog. Mater. Sci., 2023, vol. 137, p. 101131.

X.G. Fan, X.Q. Jiang, X. Zeng, Y.G. Shi, P.F. Gao, and M. Zhan: Int. J. Plast., 2018, vol. 104, pp. 173–95.

W. Li, Z. Chen, J. Liu, Q. Wang, and G. Sui: Mater. Sci. Eng. A, 2017, vol. 688, pp. 322–29.

W. Li, Z. Chen, J. Liu, S. Zhu, G. Sui, and Q. Wang: J. Mater. Sci. Technol., 2019, vol. 35, pp. 790–98.

A.S. Khan and S. Yu: Int. J. Plast., 2012, vol. 38, pp. 1–3.

M. Park, M.S. Seok Kang, G.W. Park, H.C. Kim, H.S. Moon, B. Kim, J.B. Jeon, H. Kim, H.S. Park, S.H. Kwon, and B.J. Kim: Met. Mater. Int., 2021, vol. 27, pp. 3839–55.

M. Madivalaa, A. Schwedtb, U. Prahla, and W. Blecka: Int. J. Plast., 2019, vol. 115, pp. 178–99.

S. Picak, M.W. Vaughan, O. El Atwani, A. Mott, K.R. Limmer, and I. Karaman: Acta Mater., 2023, vol. 245, p. 118589.

S.H. Zhang, L. Deng, and L.Z. Che: J. Manuf. Process., 2022, vol. 75, pp. 100–109.

S.H. Zhang, L. Deng, W.H. Tian, L.Z. Che, and Y. Li: Comput. Math. with Appl., 2022, vol. 109, pp. 58–73.

Y. Wu, R.L. Fan, M.H. Chen, K.H. Wang, J. Zhao, and W.C. **ao: Mater. Sci. Eng. A, 2021, vol. 820, p. 141560.

Y. Cao, H. Di, J. Zhang, T. Ma, and R.D.K. Misra: Mater. Sci. Eng. A, 2013, vol. 585, pp. 71–85.

X.F. Tang, B.Y. Wang, H.C. Ji, X.B. Fu, and W.C. **ao: Mater. Sci. Eng. A, 2016, vol. 675, pp. 192–203.

T.S. Byun, N. Hashimoto, and K. Farrell: Acta Mater., 2004, vol. 52, pp. 3889–99.

L. Huang, P. Hua, W. Sun, F. Liu, and F. Qi: Mater. Sci. Eng. A, 2015, vol. 647, pp. 277–86.

T. Sakaki and K. Sugimoto: ICSMA, 1985, vol. 7, pp. 239–44.

H.J. Pan, C.F. Wei, H.M. Zhang, X.Y. Li, L. Liu, J. Li, and Z.Q. Wu: Mater. Sci. Eng. A, 2023, vol. 873, p. 145025.

H.J. Pan, X.Y. Li, H.M. Zhang, L. Liu, J. Li, Y.J. Zhao, Z.J. Wang, Y. Zhang, Z.Q. Wu, M.H. Cai, and H. Ding: Mater. Sci. Eng. A, 2023, vol. 862, p. 144493.

M. Calcagnotto, D. Ponge, E. Demir, and D. Raabe: Mater. Sci. Eng. A, 2010, vol. 527, pp. 2738–46.

T.L. Li, S. Yan, and X.H. Liu: J. Mater. Res. Technol., 2021, vol. 15, pp. 708–18.

H.J. Pan, X.Y. Li, B. Qiao, Y. Zhang, N.M. Miao, L. Liu, H. Ding, and M.H. Cai: J. Mater. Eng. Perform., 2022, vol. 31(417), pp. 3228–33.

B.J. Duggan, Y.Y. Tse, G. Lam, and M.Z. Quadir: Mater. Manuf. Processes, 2011, vol. 26, pp. 51–57.

B. Eghbali: Mater. Sci. Eng. A, 2010, vol. 527, pp. 3407–10.

H. Watanabe, K. Kurimoto, T. Uesugi, Y. Takigawa, and K. Higashi: Philos. Mag., 2013, vol. 93, pp. 2913–31.

T.G. Langdon: J. Mater. Sci., 2009, vol. 44, pp. 5998–6010.

G. Sun, H. Liu, X.J. Wang, X.S. Hu, and S.S. Jiang: Mater. Char., 2021, vol. 172, p. 110879.

C.Z. Zhang, Y. **ao, K.J. Ma, Y.H. Wang, Z.P. Liu, Z.J. Liu, and W.J. Zhang: Metals, 2021, vol. 11, p. 404.

Y. Zhang, S. Chang, Y.Y. Chen, Y.C. Bai, C.L. Zhao, X.P. Wang, J.M. Xue, and H. Wang: J. Mater. Sci. Technol., 2021, vol. 95, pp. 225–36.

R. Altur, L.G. Hect, C.M. Enlo, F.A. Far, T.W. Brow: TMS. 03 April 2018.

Q.L. Wang, M.F. Novella, A. Ghiotti, and S. Bruschi: Procedia Eng., 2017, vol. 207, pp. 2161–66.

H. Masuda, T. Kanazawa, H. Tobea, and E. Sato: Scr. Mater., 2018, vol. 149, pp. 84–87.

Acknowledgments

The authors thank you for the project support from Ministry of Science and Technology of China (No. 52204382 and 52274381), Jiangsu Province (No. BK20200985), Postdoctoral Administration Office in China (No.2021M701717), and Changzhou (No. CQ20210102 and CE20225054).

Author information

Authors and Affiliations

Contributions

Haijun Pan contributed to Conceptualization, Methodology, Investigation, Writing, reviewing, & editing of the manuscript, Formal analysis, Funding acquisition, and Supervision. Chaofan Wei contributed to Resources, Data curation, and Writing of the original draft. Shunhu Zhang contributed to Visualization, Writing, reviewing, & editing of the manuscript, and Supervision. Wenhao Zhou contributed to Visualization, Writing, reviewing, & editing of the manuscript, and Supervision. Zhiqiang Wu contributed to Visualization, Writing, reviewing, & editing of the manuscript, and Supervision. Yi Zhao contributed to Writing, reviewing, & editing of the manuscript and Supervision. Lin Liu contributed to Writing, reviewing, & editing of the manuscript and Supervision.

Corresponding authors

Ethics declarations

Conflict of interest

All authors state that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Pan, H., Wei, C., Zhang, S. et al. Microstructure-Superplastic Properties Relationship and Deformation Mechanism in a Novel Dual-Phase Medium Mn Steel: The Effect of Microstructure Anisotropy and Texture. Metall Mater Trans A (2024). https://doi.org/10.1007/s11661-024-07493-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11661-024-07493-7