Abstract

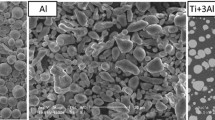

The influence of slight content of Cu as an additive on the reaction mechanism and microstructure of Ti–Al intermetallic compounds, during sintering process of Ti and Al elemental powders, was investigated. High-purity powders of Al, Ti, and Cu were used. The molar ratio of Ti/Al was equal to one. Considerable changes in reaction mechanism and heat of formation for different samples with different heating rates and different additive contents during combustion synthesis process were observed. The temperature was monitored by a data acquisition system or DAS. The samples were analyzed by XRD and SEM techniques. According to the experimental findings, complete formation of products was achieved at distinct additive content and heating rate. The initial reaction temperature and the samples’ porosities were lowered by the addition of Cu. The sample hardness varied depending on the heating rate and Cu content.

Similar content being viewed by others

Notes

Data Acquisition System

low heating rate

high heating rate

References

Q. Wan, F. Li, W. Wang, J. Hou, W. Cui, and Y. Li: Materials, 2019, vol. 12, p. 1967. https://doi.org/10.3390/ma12121967.

N. Kochetov and A.E. Sytschev: Mater. Chem. Phys., 2021, vol. 257, p. 123727. https://doi.org/10.1016/j.matchemphys.2020.123727.

M. Yamaguchi, H. Inui, and K. Ito: Acta Mater., 2000, vol. 48(1), pp. 307–22. https://doi.org/10.1016/S1359-6454(99)00301-8.

P. Tan, H.P. Tang, X.T. Kang, Q.B. Wang, J.L. Zhu, C. Li, and J.M. Chen: Mater. Trans., 2009, vol. 50(10), pp. 2484–87. https://doi.org/10.2320/matertrans.M2009120.

A. Školáková, P. Salvetr, P. Novák, and D. Vojtěch: Acta Phys. Pol. A, 2018, vol. 134, pp. 743–47. https://doi.org/10.12693/APhysPolA.134.743.

K. Karczewski, S. Jóźwiak, M. Chojnacki, and Z. Bojar: Intermetallics, 2010, vol. 18(7), pp. 1401–04. https://doi.org/10.1016/j.intermet.2010.02.018.

E. Levashov, A.S. Mukasyan, A.S. Rogachev, and D.V. Shtansky: Int. Mater. Rev., 2017, vol. 62(4), pp. 203–39. https://doi.org/10.1080/09506608.2016.1243291.

M. Lagos, I. Agote, M. Gutiérrez, A. Sargsyan, and L. Pambaguian: Int. J. Self-Propagating High-Temp. Synth., 2010, vol. 19(1), pp. 23–27. https://doi.org/10.3103/S1061386210010048.

X. Jiao, Y. Liu, X. Cai, J. Wang, and P. Feng: J. Mater. Sci., 2021, https://doi.org/10.1007/s10853-021-06035-5.

K. Karczewski, S. Jóźwiak, M. Chojnacki, and Z. Bojar: Intermetallics, 2011, vol. 19(10), pp. 1555–62. https://doi.org/10.1016/j.intermet.2011.05.029.

S. Mehrabani, A.T. Tabrizi, H. Aghajani, and H. Pourbagheri: Int. J. Self-Propagating High-Temp. Synth., 2020, vol. 29(3), pp. 167–72. https://doi.org/10.3103/S1061386220030061.

J.J. Moore and H.J. Feng: Prog. Mater. Sci., 1995, vol. 39(4–5), pp. 243–73. https://doi.org/10.1016/0079-6425(94)00011-5.

S. Arabpour Javadi, S. Nozohour Hokmabadi, A. Taghizadeh Tabrizi, and H. Aghajani: Powder Metall., 2021, vol. 64(5), pp. 341–50. https://doi.org/10.1080/00325899.2021.1906564.

M. Busurina, A.E. Sychev, I.D. Kovalev, A.V. Karpov, and N.V. Sachkova: Combust. Explos. Shock Waves, 2020, vol. 56(3), pp. 317–23. https://doi.org/10.1134/S0010508220030089.

Z. Deng, H. Yin, C. Zhang, G. Zhang, T. Zhang, Z. Liu, H. Wang, and X. Qu: Prog. Nat. Sci.-Mater., 2019, vol. 29(4), pp. 425–31. https://doi.org/10.1016/j.pnsc.2019.04.007.

A. Hibino and R. Watanabe: Nippon Kinzoku Gakkaishi/ J. Jpn. Inst., 1991, vol. 55(11), pp. 1256–62. https://doi.org/10.2320/**stmet1952.55.11_1256.

H. Yi, A. Petric, and J.J. Moore: J. Mater. Sci., 1992, vol. 27(24), pp. 6797–6806. https://doi.org/10.1007/BF01165971.

V. Sanin, M.R. Filonov, V.I. Yukhvid, Yu.A. Anikin, and D.M. Ikornikov: Russ. J. Non-Ferr. Met., 2020, vol. 61(1), pp. 119–25. https://doi.org/10.3103/S1067821220010137.

H. Okamoto and T.B. Massalski: Binary Alloy Phase Diagrams, ASM International, Materials Park, 1990. https://doi.org/10.31399/asm.hb.v03.9781627081634.

A. Hibino, Y. Sumiyoshi, and K. Hayashi: J. Jpn. Soc. Powder Powder Metall., 2011, vol. 58, pp. 625–32. https://doi.org/10.2497/jjspm.58.625.

H.-W. Liu and K.P. Plucknett: Adv. Powder Technol., 2017, vol. 28(1), pp. 314–23. https://doi.org/10.1016/j.apt.2016.10.001.

U. Kattner, J.-C. Lin, and Y.A. Chang: Metall. Trans. A, 1992, vol. 23, pp. 2081–90. https://doi.org/10.1007/BF02646001.

P. Wang, Z. Chen, C. Hu, B. Li, J. Lin, and Q. Liu: J. Mater. Res. Technol., 2020, vol. 9(5), pp. 11813–25. https://doi.org/10.1016/j.jmrt.2020.08.070.

R. Khoshhal, M. Soltanieh, and M. Mirjalili: Iran. J. Mater. Sci. Eng., 2010, vol. 7(1), pp. 24–31.

S.-M. Liang and R. Schmid-Fetzer: Calphad, 2015, vol. 51, pp. 252–60. https://doi.org/10.1016/j.calphad.2015.10.004.

P. Canale and C. Servant: Z. Met., 2002, vol. 93(4), pp. 273–76. https://doi.org/10.3139/146.020273.

D. Kumar, M. Singh, and A.K. Singh: AIP Conference Proceedings, AIP Publishing LLC, 2018. https://doi.org/10.1063/1.5032520.

F.R. Boer, R. Boom, W.C.M. Mattens, A.R. Miedema, A.K. Niessen, Cohesion in metals: Transition Metal Alloys, vol. 1, North Holland, Amsterdam, 1988.

W. Oelsen and W. Middel: Verlag Stahleisen, 1937.

R. Sinvhal and P.R. Khangaonkar: Trans. Indian Inst. Met., 1967, vol. 20, pp. 107–10.

O. Kubaschewski and G. Heymer: J. Chem. Soc. Faraday Trans., 1960, vol. 56, pp. 473–78. https://doi.org/10.1039/TF9605600473.

J. Hair and D.B. Downie: Faraday Symposia of the Chemical Society, Royal Society of Chemistry, London, 1973. https://doi.org/10.1039/FS9730800056.

V. Witusiewicz, U. Hecht, S.G. Fries, and S. Rex: J. Alloys Compd., 2004, vol. 385(1–2), pp. 133–43. https://doi.org/10.1016/j.jallcom.2004.04.126.

M.A. Majid and R. Yousefi: Solid State Sci., 2011, vol. 13(1), pp. 251–56. https://doi.org/10.1016/j.solidstatesciences.2010.11.024.

Y.T. Prabhu, K.V. Rao, V.S.S. Kumar, and B.S. Kumari: World J. Nano Sci. Eng., 2014, https://doi.org/10.4236/wjnse.2014.41004.

C. Suryanarayana and M. Grant Norton: X-ray Diffraction, Springer, New York, 1998, pp. 63–94.

A. Mishra, H. Roy, A. Lohar, S. Samanta, S. Tiwari, and K. Dutta: Mater. Sci. Eng., 2015, https://doi.org/10.1088/1757-899X/75/1/012001.

Funding

This work was not granted or funded (financially, non-financially, directly, or indirectly) by any company or institution.

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jafarzadeh, M., Soltanieh, M. & Khoshhal, R. The Influence of Cu on Combustion Synthesis Mechanism of Ti–Al Intermetallic Compounds Produced From Ti and Al Elemental Powders. Metall Mater Trans A 54, 3537–3549 (2023). https://doi.org/10.1007/s11661-023-07111-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-023-07111-y