Abstract

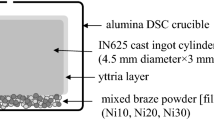

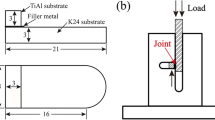

A new multi-principal-component alloy (MPCA) filler metal with the composition Fe5Co20Ni20Mn35Cu20 was designed for brazing Ni-base Alloy 600 (Ni-Cr-Fe). Thermodynamic calculations, including atomic size difference, mixing entropy and enthalpy, valence electron concentration, and phase diagram calculations were used to optimize the composition of the MPCA filler material, targeting a face-centered cubic (FCC) crystalline structure and a melting point appropriate for brazing. An X-ray diffraction measurement confirmed the presence of an FCC structure in the as-cast MPCA, and differential thermal analysis (DTA) results demonstrated its melting range to be 1080-1150 °C. The MPCA also exhibited mechanical properties worthy of a brazing filler candidate, with a true compressive yield stress of 286 MPa, an ultimate compressive strength of 591 MPa, and a fracture strain of 106 pct. The optimum brazing temperature was determined to be 1200 °C through a wettability test on the Alloy 600 base material, at which the MPCA exhibited a low wetting angle of 14 deg and optimal spreading behavior. The MPCA plate was cold rolled into 300 μm foils for brazing. For the full range of brazing times studied (15 to 120 minutes), no microstructural defects were observed, and electron backscatter diffraction (EBSD) results showed equiaxed grains present in the solidification microstructure of the filler material. Using data from energy-dispersive spectroscopy (EDS), a kinetic analysis was performed for the constituent elements in the MPCA. It was determined that although Mn was the fastest diffusing of the elements that diffused from the MPCA into the Alloy 600, the diffusion coefficients for all of these elements were on the same order of magnitude. This result was indicative of the sluggish diffusion theory associated with MPCAs. The effect of brazing time on the shear strength of the brazed joint was evaluated. A maximum shear strength of 530 MPa was achieved at a brazing time of 90 minutes. As brazing time increased up to 90 minutes, the increasing interdiffusion distance facilitated a stronger metallurgical bond. However, beyond 90 minutes, the formation of brittle Cr2Mn3 and CrMn3 intermetallic compounds at the grain boundaries within the filler foil led to a lower shear strength and brittle fracture in the joint.

Similar content being viewed by others

Data Availability

The raw/processed data required to reproduce these findings cannot be shared at this time as the data also form part of an ongoing study.

References

1. R. Kennedy, Superalloys 2005, vol. 718, pp. 1-14.

B. Muralidharan, V. Shankar, and T. Gill: Weldability of Inconel 718-A review, Indira Gandhi Centre for Atomic Research, 1996.

3. J. P. Collier, S. H. Wong, J. K. Tien and J. C. Phillips, Metallurgical and Materials Transactions A 1988, vol. 19, pp. 1657-1666.

4. D. Furrer and H. Fecht, JOM 1999, vol. 51, pp. 14-17.

5. A. Pineau and S. D. Antolovich, Engineering Failure Analysis 2009, vol. 16, pp. 2668-2697.

6. T. M. Pollock and S. Tin, Journal of Propulsion and Power 2006, vol. 22, pp. 361-374.

D. Duvall, W. Owczarski, D. Paulonis, and W. King, Weld. J., 1972, vol. 51, pp. 41S-49S.

G. Q. Chen, B. G. Zhang, T. M. Lü and J. C. Feng, Transactions of Nonferrous Metals Society of China 2013, vol. 23, pp. 1971-1976.

9. D. Y. Kim, J. H. Hwang, K. S. Kim and J. G. Youn, Transaction of ASME, Indianapolis, Indiana, United States 1999.

10. G. Ma, D. Wu, F. Niu and H. Zou, Optics and Lasers in Engineering 2015, vol. 72, pp. 39-46.

11. M. Montazeri, F. M. Ghaini and O. Ojo, Weld. J 2013, vol. 92, pp. 258s-264s.

A.S. Suharno, R.E. Buntario and D. Widagdo, et al.: Glob. J. Res. Eng., 2012, vol. 12, pp. 22-28.

13. O. Ojo, N. Richards and M. Chaturvedi, Scripta Materialia 2004, vol. 50, pp. 641-646.

14. M. Qian and J. Lippold, Acta Mater 2003, vol. 51, pp. 3351-3361.

J. C. Lippold, S. D. Kiser and J. N. DuPont: Welding Metallurgy and Weldability of Nickel-Base Alloys. (Wiley, Hoboken, 2011).

K.H. Holko and T.J. Moore: Report No. NASA TN D-6493, NASA, Lewis Research Center, NASA, Cleveland, OH, 1971.

17. A. Shapiro and A. Rabinkin, Welding Journal 2003, vol. 82, pp. 36-43.

R. D. Nascimento, A. Martinelli and A. Buschinelli: Cerâmica 2003, vol. 49, pp. 178-198.

19. A. Rabinkin, Science and Technology of Welding and Joining 2004, vol. 9, pp. 181-199.

D. M. Jacobson and G. Humpston: Principles of Brazing. (ASM International, Materials Park, 2005).

21. M. Pouranvari, A. Ekrami and A. Kokabi, Materials Science and Technology 2013, vol. 29, pp. 980-984.

22. M. Mosallaee, A. Ekrami, K. Ohsasa and K. Matsuura, Metallurgical and Materials Transactions A 2008, vol. 39, pp. 2389-2402.

R. M. Evans and R. E. Monroe: Welding and Brazing of Nickel and Nickel-Base Alloys: A Report (Technology Utilization Office, National Aeronautics and Space Administration;[for sale by the Supt. of Docs., US Govt. Print. Off.], 1972).

M. Chaturvedi, O. Ojo, and N. Richards, Adv. Technol. Mater. Mater. Process. J. (ATM) 2004, vol. 6, p. 206.

25. A. Khorram, M. Ghoreishi, M. Torkamany and M. Bali, Optics & Laser Technology 2014, vol. 56, pp. 443-450.

W. M. Miglietti and R. C. Pennefather: in ASME 1996 International Gas Turbine and Aeroengine Congress and Exhibition, American Society of Mechanical Engineers, 1996, pp. V005T12A010–V005T12A010.

27. A. Khorram, O. Fakhraei and M. Torkamany, The International Journal of Advanced Manufacturing Technology 2017, vol. 88, pp. 2075-2084.

28. M. Schwartz, Gold Bulletin 1975, vol. 8, pp. 102-110.

B. S. Murty, J. W. Yeh and S. Ranganathan: High-Entropy Alloys (Butterworth-Heinemann, Oxford, 2014).

30. B. Cantor, I. Chang, P. Knight and A. Vincent, Materials Science and Engineering: A 2004, vol. 375, pp. 213-218.

31. J. W. Yeh, S. K. Chen, S. J. Lin, J. Y. Gan, T. S. Chin, T. T. Shun, C. H. Tsau and S. Y. Chang, Advanced Engineering Materials 2004, vol. 6, pp. 299-303.

32. D. Miracle and O. Senkov, Acta Mater 2017, vol. 122, pp. 448-511.

33. X. Yang and Y. Zhang, Materials Chemistry and Physics 2012, vol. 132, pp. 233-238.

34. W. Liu, Y. Wu, J. He, T. Nieh and Z. Lu, Scripta Materialia 2013, vol. 68, pp. 526-529.

35. C.-J. Tong, Y.-L. Chen, J.-W. Yeh, S.-J. Lin, S.-K. Chen, T.-T. Shun, C.-H. Tsau and S.-Y. Chang, Metallurgical and Materials Transactions A 2005, vol. 36, pp. 881-893.

36. C. J. Tong, M. R. Chen, J. W. Yeh, S. J. Lin, S. K. Chen, T. T. Shun and S. Y. Chang, Metallurgical and Materials Transactions A 2005, vol. 36, pp. 1263-1271.

37. C. W. Tsai, Y. L. Chen, M. H. Tsai, J. W. Yeh, T. T. Shun and S. K. Chen, Journal of Alloys and compounds 2009, vol. 486, pp. 427-435.

38. L. H. Wen, H. C. Kou, J. S. Li, H. Chang, X. Y. Xue and L. Zhou, Intermetallics 2009, vol. 17, pp. 266-269.

39. C. Y. Hsu, C. C. Juan, W. R. Wang, T. S. Sheu, J. W. Yeh and S. K. Chen, Materials Science and Engineering: A 2011, vol. 528, pp. 3581-3588.

40. W. Woo, E.-W. Huang, J.-W. Yeh, H. Choo, C. Lee and S.-Y. Tu, Intermetallics 2015, vol. 62, pp. 1-6.

41. M. H. Chuang, M. H. Tsai, W. R. Wang, S. J. Lin and J. W. Yeh, Acta Mater 2011, vol. 59, pp. 6308-6317.

42. Y. L. Chou, J. W. Yeh and H. C. Shih, Corrosion Science 2010, vol. 52, pp. 2571-2581.

43. H. T. Hsueh, W. J. Shen, M. H. Tsai and J. W. Yeh, Surface and Coatings Technology 2012, vol. 206, pp. 4106-4112.

44. Z. Tang, L. Huang, W. He and P. K. Liaw, Entropy 2014, vol. 16, pp. 895-911.

45. T. Butler, J. Alfano, R. Martens and M. Weaver, Jom 2015, vol. 67, pp. 246-259.

46. T. M. Butler and M. L. Weaver, Journal of Alloys and Compounds 2016, vol. 674, pp. 229-244.

Y. Zhang, T. Zuo, Y. Cheng and P. K. Liaw, Scientific Reports 2013, vol. 3, p. 1451.

48. O. N. Senkov, G. B. Wilks, J. M. Scott and D. B. Miracle, Intermetallics 2011, vol. 19, pp. 698-706.

49. K. Y. Tsai, M. H. Tsai and J. W. Yeh, Acta Mater 2013, vol. 61, pp. 4887-4897.

J.W. Yeh, Eur. J. Control 2006, vol. 31, pp. 633-648.

51. W. H. Liu, Y. Wu, J. Y. He, T. G. Nieh and Z. P. Lu, Scripta Mater 2013, vol. 68, pp. 526-529.

52. D. L. Beke and G. Erdelyi, Materials Letters 2016, vol. 164, pp. 111-113.

53. J. Dabrowa, W. Kucza, G. Cieslak, T. Kulik, M. Danielewski and J. W. Yeh, J Alloy Compd 2016, vol. 674, pp. 455-462.

54. K. **, C. Zhang, F. Zhang and H. Bei, Materials Research Letters 2018, vol. 6, pp. 293-299.

55. A. Takeuchi and A. Inoue, Materials Transactions, JIM 2000, vol. 41, pp. 1372-1378.

56. A. Takeuchi and A. Inoue, Materials Transactions 2005, vol. 46, pp. 2817-2829.

57. F. R. Boer and D. G. Perrifor: Cohesion in Metals. (Elsevier Science Publisher B.V., Netherlands, 1988).

58. Y. Zhang, Y. J. Zhou, J. P. Lin, G. L. Chen and P. K. Liaw, Advanced Engineering Materials 2008, vol. 10, pp. 534-538.

59. S. Guo, C. Ng, J. Lu and C. Liu, Journal of applied physics 2011, vol. 109, pp. 103505-1-103505-5.

60. D. Bridges, S. Zhang, S. Lang, M. Gao, Z. Yu, Z. Feng and A. Hu, Mater Lett 2018, vol. 215, pp. 11-14.

AWS Standard C3.2: Standard Method for Evaluating the Strength of Brazed Joints, 2008.

Special Metals Huntington Alloys Corporation, Certified Materials Test Report: Inconel Alloy 600, EAF-AOD-Electroslag Remelted, Hot Rolled Plate, Descaled, Annealed, TA, Chen International, Inc.

S. D. Nelson: Multiphase Wide Gap Braze Alloys for the Repair of Nickel-Base Superalloy Turbine Components: Development and Characterization. (Colorado School of Mines, Golden, 2013).

64. C. Y. Su, C. P. Chou, B. C. Wu and W. C. Lih, Materials Science and Technology 1999, vol. 15, pp. 316-322.

65. S. Kou: Welding Metallurgy. 2 ed. (Wiley, Hoboken, NJ, 2003).

66. W. F. Gale and D. A. Butts, Science and Technology of Welding and Joining 2004, vol. 9, pp. 283-300.

67. F. J. A. DenBroeder, Scripta Metallurgica 1969, vol. 3, pp. 321-326.

68. C. L. Fu, R. Reed, A. Janotti and M. Krcmar, Superalloys 2004, vol. 2004, pp. 867-876.

69. T. Zaharinie, F. Yusof, M. Hamdi, T. Ariga and R. Moshwan, The International Journal of Advanced Manufacturing Technology 2014, vol. 73, pp. 1133-1140.

70. X. Zhou, Y. Wang, J. Zhou, G. Qu and Z. Bao, Acta Metallurca Sinica-Chinese Edition 2007, vol. 43, pp. 433-438.

71. K. J. Laws, C. Crosby, A. Sridhar, P. Conway, L. S. Koloadin, M. Zhao, S. Aron-Dine and L. C. Bassman, Journal of Alloys and Compounds 2015, vol. 650, pp. 949-961.

72. V. Bazhenov, Russian Journal of Non-Ferrous Metals 2013, vol. 54, pp. 171-177.

73. J. S. Shyu and T. H. Chuang, Journal of Materials Engineering and Performance 1996, vol. 5, pp. 84-88.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted February 21, 2019.

Rights and permissions

About this article

Cite this article

Gao, M., Schneiderman, B., Gilbert, S.M. et al. Microstructural Evolution and Mechanical Properties of Nickel-Base Superalloy Brazed Joints Using a MPCA Filler. Metall Mater Trans A 50, 5117–5127 (2019). https://doi.org/10.1007/s11661-019-05386-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-019-05386-8