Abstract

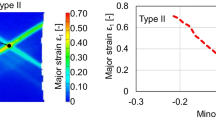

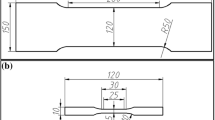

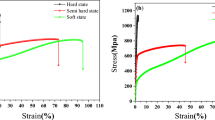

The objective of this paper is to characterize the mechanical behavior of an ultra-thin stainless steel, of 0.15-mm thickness, that is commonly used in the manufacturing of miniature connectors. The main focus is the relationship between some microstructural features, like grain size and surface roughness, and the macroscopic mechanical behavior investigated in uniaxial tension and simple shear. In tension, adaptations to the very small sheet thickness, in order to hold the specimen under the grips, are presented. Yield stress, initial elastic modulus, and evolution of the loading–unloading slope with plastic deformation were evaluated. Moreover, the kinematic contribution to the hardening was characterized by monotonic and cyclic simple shear test and reproduced by a mixed hardening law implemented in Abaqus finite element code. Then, the evolution of surface roughness with plastic strain, both in tension and simple shear, was analyzed. It was shown that in the case of an ultra-thin sheet, the stress levels, calculated either from an average thickness or when considering the effect of the surface roughness, exhibit a significant difference. Finally, the influence of surface roughness on the fracture of a tensile specimen was also investigated.

Similar content being viewed by others

References

M. Geiger, M. Kleiner, R. Eckstein, N. Tiesler, U. Enge, CIRP Ann.: Manuf. Technol. 50, 445–62 (2001)

T. Connolley, P.E. Mchugh, M. Bruzzi, Fatigue Fract. Eng. Mater. Struct. 28, 1119–52 (2005)

U. Engel, R. Eckstein, J. Mater. Process. Technol. 125–126, 35–44 (2002)

G.T. Gau, P.H. Chen, H. Gu, R.S. Lee, J. Mater. Process. Technol. 213, 376–82 (2013)

Nisshin Steel—Nisshin Steel Quality Products: Stainless Foil

E.M. Costache, N. Nanu, B. Chirita, G. Brabie, Int. J. Mech. Sci. 69, 125–140 (2013)

L. Peng, P. Hu, X. Lai, D. Mei, J. Ni, Mater. Des. 30, 783–790 (2009)

Lester Metals LLC. Stainless Steel Products. http://www.lestermetals.com

Alufoil (EAFA) European Aluminum Foil Association. http://www.alufoil.org/facts.html

H. Hoffmann, S. Hong, CIRP Ann.: Manuf. Technol. 55, 263–266 (2006)

T. Furushima, H. Tsunezaki, K. Manabe, S. Alexsandrov, Int. J. Mach. Tool Manuf. 76, 34–48 (2014)

T. Furushima, H. Tsunezaki, K. Manabe, and S. Alexsandrov: 13th International Conference on Fracture, Bei**g, China. 2013

S. Miyazaki, K. Shibata, H. Fujita, Acta Metall. 27, 855–862 (1979)

F. Vollertsen, Micro Metal Forming (Springer, Berlin, 2013)

N. Hansen, Acta Metall. 25, 863–869 (1977)

J. Xu, B. Guo, D. Shan, M. Li, Z. Wang, Mater. Trans. 54, 984–989 (2013)

S. Mahabunphachai, M. Koç, Int. J. Mach. Tool Manuf. 48, 1014–1029 (2008)

P.J.M. Janssen, J.P.M. Hoefnagels, T.H. Keijser, M.G.D. Geers, J. Mech. Phys. Solids 56, 2687–2706 (2008)

T. Furushima, H. Tsunezaki, T. Nakayama, K. Manabe, S. Alexsandrov, Key Eng. Mater. 554–557, 169–173 (2013)

O. Wouters, W.P. Vellinga, R. Van Tijum, J.T.M. Hosson, Acta Mater. 53, 4043–4050 (2005)

H.A. Al-Qureshi, A.N. Klein, M.C. Fredel, J. Mater. Process. Technol. 170, 204–210 (2005)

W.L. Chan, M.W. Fu, J. Mater. Process. Technol. 212, 1501–1512 (2012)

J.G. Liu, M.W. Fu, J. Lu, W.L. Chan, Comput. Mater. Sci. 50, 2604–2614 (2011)

M. Klein, A. Hadrboletz, B. Weiss, G. Khatibi, Mater. Sci. Eng. A 319–321, 924–928 (2001)

T. Mizuno, H. Mulk, Wear 198, 176–184 (1996)

M.W. Fu, W.L. Chan, Mater. Des. 32, 4738–4746 (2011)

I. Ragai, D. Lazim, J.A. Nemes, J. Mater. Process. Technol. 166, 116–127 (2005)

S. Li, R.H. Wagoner, Int. J. Plast. 27, 1126–1144 (2011)

S. Thuillier, P.Y. Manach, Int. J. Plast. 25, 733–751 (2009)

C.H. Pham, S. Thuillier, P.Y. Manach, J. Mater. Process. Technol. 214, 844–855 (2014)

C.H. Pham, S. Thuillier, and P.Y. Manach: The 9th International Conference and Workshop on Numerical Simulation of 3D Sheet Metal Forming Processes, Melbourne, Australia, 2014, vol. 1567, pp. 422–427.

T.A. Kals, R. Eckstein, J. Mater. Process. Technol. 103, 95–101 (2000)

B.S. Katharine, A.E. David, A.C. Todd, Adv. Mater. Process. 166, 32–37 (2008)

ASTM E112–10. Standard test methods for determining average grain size. ASTM International, West Conshohocken 2010

S.A. Parasiz, R. VanBenthysen, B.L. Kinsey, J. Manuf. Sci. Eng. 132, 011–018 (2010)

G.T. Gau, C. Principe, J. Wang, J. Mater. Process. Technol. 184, 42–46 (2007)

C.J. Wang, D.B. Shan, J. Zhou, B. Guo, L.N. Sun, J. Mater. Process. Technol. 187–188, 256–269 (2007)

INSTRON Corporation. Instron Series 5500 Load Frames Including Series 5540, 5560, 5580. M10–14190-EN, Revision A 2007

G.T. Gau, C. Principe, M. Yu, J. Mater. Process. Technol. 191, 7–10 (2007)

ISO 6892–1:2009(E). Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature

ASTM E8/E8M. Standard test methods for tension testing of metallic materials. ASTM International, West Conshohocken 2009

Faerber J. Microscopie électronique à balayage, Microanalyse X par sonde électronique. Institut de Physique et Chimie des matériaux de Strabourg, Strasbourg, France 2004

H. Kim, C. Kim, F. Barlat, E. Pavlina, M.G. Lee, Mater. Sci. Eng. A 562, 161–171 (2013)

P.Y. Manach, N. Couty, Comput. Mech. 28, 17–25 (2002)

S. Bouvier, H. Haddadi, P. Levée, C. Teodosiu, J. Mater. Process. Technol. 172, 96–103 (2006)

L. Yang, L. Lu, Scripta Mater. 69, 242–245 (2013)

S. Gallée, P.Y. Manach, S. Thuillier, Mater. Sci. Eng. A 466, 47–55 (2007)

Z. Tourki, H. Bargui, H. Sidhom, J. Mater. Process. Technol. 166, 330–336 (2005)

L. Joshua, T. Chester, M. Martin, Metall. Mater. Trans. A 37A, 147–161 (2006)

D.Y. Ryoo, N. Kang, C.Y. Kang, Mater. Sci. Eng. A 528, 2277–2281 (2011)

K. Yamaguchi, H. Adachi, N. Takakura, Met. Mater. Int. 4, 420–425 (1998)

M. Vrh, M. Halilovič, B. Štok, Exp. Mech. 51, 677–695 (2011)

P.A. Eggertsen, K. Mattiasson, Int. J. Mech. Sci. 51, 547–563 (2009)

C.H. Pham, S. Thuillier, and P.Y. Manach: Steel Res. Int., 2015

M.A. Sutton, J.D. Helm, M.L. Boone, Int. J. Fract. 109, 285–301 (2001)

J. Bron, J. Besson, A. Pineau, Mater. Sci. Eng. A 380, 356–364 (2004)

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted June 27, 2014.

Rights and permissions

About this article

Cite this article

Pham, CH., Thuillier, S. & Manach, PY. Mechanical Properties Involved in the Micro-forming of Ultra-thin Stainless Steel Sheets. Metall Mater Trans A 46, 3502–3515 (2015). https://doi.org/10.1007/s11661-015-2978-1

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-015-2978-1