Abstract

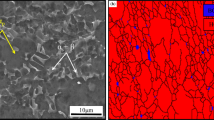

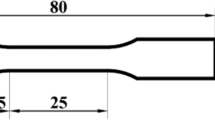

Cyclic deformation and damage behavior of a Ni-free high-nitrogen austenitic stainless steel with a composition of Fe-18Cr-18Mn-0.63N (weight pct) were studied, and the internal stress and effective stress were estimated by partitioning the hysteresis loop during cyclic straining at total strain amplitudes ranging from 3.0 × 10−3 to 1.0 × 10−2. It is found that immediate cyclic softening takes place at all strain amplitudes and subsequently a saturation or quasi-saturation state develops and occupies the main part of the whole fatigue life. The internal stress increases with increasing strain amplitude, while the variation of effective stress with strain amplitude is somewhat complicated. Such a phenomenon is discussed in terms of dislocation structures and the short-range ordering caused by the interaction between nitrogen atoms and substitutional atoms. The relationship of fatigue life vs plastic strain amplitude (N f−Δε pl/2) follows a bilinear Coffin–Manson rule, resulting from the variation in slip deformation mode with the applied strain amplitude. At the low strain amplitude, cracks initiate along slip bands, and planar slip dislocation configurations dominate the major characteristic of internal microstructures. At high strain amplitudes, intergranular (mostly along grain boundaries and few along twin boundaries) cracks are generally found, and the deformation microstructures are mainly composed of dislocation cells, stacking faults and a small amount of deformation twins, in addition to planar slip dislocation structures.

Similar content being viewed by others

References

J.W. Simmons, Mater. Sci. Eng. A, 1996, vol. 207, pp. 159–69.

P.J. Uggowitzer, R. Magdowski, and M.O. Speidel, ISIJ Int., 1996, vol. 36, pp. 901–908.

F. Shi, X.W. Li, Y. Qi, and C.M. Liu, Key Eng. Mater., 2013, vols. 531–532, pp. 97–102.

F. Shi, X.W. Li, Y. Qi, and C.M. Liu, Steel Res. Int., 2013, vol. 84, pp. 1034–39.

D. Kuroda, S. Hiromoto, T. Hanawa, and Y. Katada, Mater. Trans., 2002, vol. 43, pp. 3100–04.

C.W. Shao, F. Shi, W. W. Guo, and X.W. Li, Mater. Trans., 2014, vol. 56, pp. 46–53.

N. Maruyama, S. Hiromoto, E. Akiyama, and M. Nakamura, Sci. Technol. Adv. Mater., 2013, vol. 14, p. 025002.

M. Sumita, T. Hanawa, and S.H. Teoh, Mater. Sci. Eng. C, 2004, vol. 24, pp. 753–60.

D. Kuroda, T. Hanawa, T. Hibaru, S. Kuroda, and M. Kobayashi, Mater. Trans., 2003, vol. 44, pp. 1363–69.

M. Sagara, H. Uno, Y. Katada, and T. Kodama, J. Iron Steel Inst. Jpn., 2002, vol. 88, pp. 672–77.

K. L. Chao, H. Y. Liao, J. J. Shyue, and S. S. Lian, Metall. Mater. Trans. B, 2014, vol. 45B, pp. 381–91.

N. Maruyama, M. Sanbe, Y. Katada, and K. Kanazawa, Mater. Trans., 2009, vol. 50, pp. 2615–22.

A.H. Cottrell: Dislocation and Plastic Flow in Crystals, Clarendon Press, Oxford, 1953.

M.S. Pham, S.R. Holdsworth, K.G.F. Janssens, and E. Mazza, Int. J. Plasticity, 2013, vol. 47, pp. 143–64.

M.S. Pham and S.R. Holdsworth, Metall. Mater. Trans. A, 2014, vol. 45A, pp. 738–51.

J. Polák, F. Fardoun, and S. Degallaix, Mater. Sci. Eng. A, 1996, vol. 215, pp. 104–12.

D. Kuhlmann-Wilsdorf and C. Laird, Mater. Sci. Eng., 1979, vol. 37, pp. 111–20.

J.I. Dickson, J. Boutin, and L. Handfield, Mater. Sci. Eng., 1984, vol. 64, pp. L7–L11.

S. Heino and B. Karlsson, Acta Mater., 2001, vol. 49, pp. 339–51.

B. Chang and Z. Zhang, Mater. Sci. Eng. A, 2012, vol. 556, pp. 625–32.

M.L.G. Byrnes, M. Grujicic, and W.S. Owen, Acta Mater., 1987, vol. 35, pp. 1853–62.

J. Polák, F. Fardoun, and S. Degallaix, Mater. Sci. Eng. A, 2001, vol. 297, pp. 154–61.

M. Nyström, U. Lindstedt, B. Karlsson, and J.O. Nilsson, Mater. Sci. Technol., 1997, vol. 13, pp. 560–67.

J.B. Vogt, J. Mater. Process. Technol., 2001, vol. 117, pp. 364–69.

Z.J. Zhang, P. Zhang, L.L. Li, and Z.F. Zhang, Acta Mater., 2012, vol. 60, pp. 3113–27.

P. Zhang, Z.J. Zhang, L.L. Li, and Z.F. Zhang, Scripta Mater., 2012, vol. 66, pp. 854–59.

L.L. Li, Z.J. Zhang, P. Zhang, Z.G. Wang, and Z.F. Zhang. Nat. Commun., 2013, vol. 5, p. 3536.

X.W. Li, Z.G. Wang, Y.W. Zhang, S.X. Li, and Y. Umakoshi, Phys. Stat. Sol. (a), 2002, vol. 191, pp. 97–105.

X. W. Li, Y. Umakoshi, B. Gong, S.X. Li, and Z.G. Wang, Mater. Sci. Eng. A, 2002, vol. 333, pp. 51–59.

B. Bay, N. Hansen, D.A. Hughes, and D. Kuhlmann-Wilsdorf, Acta Metall. Mater., 1992, vol. 40, pp. 205–19.

J. Kratochvíl, M. Kružík, and R. Sedláček, Int. J. Eng. Sci., 2010, vol. 48, pp. 1401–12.

T. Kruml and S. Degallaix, Acta Mater., 1997, vol. 45, pp. 5145–51.

K. Obrtlik, T. Kruml, and J. Polak, Mater. Sci. Eng. A, 1994, vol. 187, pp. 1–9.

W.Y. Maeng and M.H. Kim, J. Nucl. Mater., 2000, vol. 282, pp. 32–39.

V. Gavriljuk, Y. Petrov, and B. Shanina, Scripta Mater., 2006, vol. 55, pp. 537–40.

X. W. Li, X. M. Wu, Z. G. Wang, and Y. Umakoshi, Metall. Mater. Trans. A, 2003, vol. 34A, pp. 307–18.

X.W. Li, N. Peng, X.M. Wu, and Z.G. Wang, Metall. Mater. Trans. A, 2014, vol. 45A, pp. 3835–43.

K. Oda, N. Kondo, and K. Shibata, ISIJ Int., 1990, vol. 30, pp. 625–31.

S. Kalnaus and Y. Jiang, ASME J. Eng. Mater. Technol., 2008, vol. 130, p. 031013.

V.G. Gavriljuk and H. Berns: High Nitrogen Steels: Structure, Properties, Manufacture, Applications, 1st ed., Springer Verlag Press, Berlin, 1999.

G.V. Prasad Reddy, R. Sandhya, S. Sankaran, and M.D. Mathew: Metall. Mater. Trans. A, 2014, vol. 45A, pp. 5044–56.

V. Singh, M. Sundararaman, W. Chen, and R.P. Wahi, Metall. Trans. A, 1991, vol. 22A, pp. 499–506.

V.S. Sarma, M. Sundararaman, and K.A. Padmanabhan, Mater. Sci. Technol., 1998, vol. 14, pp. 669–75.

I. Karaman, H. Sehitoglu, H.J. Maier, and Y.I. Chumlyakov, Acta Mater., 2001, vol. 49, pp. 3919–33.

J.B. Vogt, A. Messai, and J. Foct, Scripta Metall. Mater., 1994, vol. 31, pp. 549–54.

S. Heino and B. Karlsson, Acta Mater., 2001, vol. 49, pp. 353–63.

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (NSFC) under Grant nos. 51231002, 51271054, and 51201027, and also by the Fundamental Research Funds for the Central Universities of China under Grant nos. N110105001, N120405001, and N120505001. The authors would like to thank Z. F. Gao and B. Wang for their assistance in SEM observations and fatigue tests.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted September 28, 2014.

Rights and permissions

About this article

Cite this article

Shao, C.W., Shi, F. & Li, X.W. Cyclic Deformation Behavior of Fe-18Cr-18Mn-0.63N Nickel-Free High-Nitrogen Austenitic Stainless Steel. Metall Mater Trans A 46, 1610–1620 (2015). https://doi.org/10.1007/s11661-015-2769-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-015-2769-8