Abstract

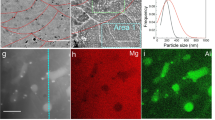

A new type of lightweight AlNiLa medium entropy amorphous alloy composite ribbons (labled as MEAAC ribbons) were prepared by vacuum arc melting technology and high-speed single roller melt-spinning method. The microstructure and thermal stability of MEAAC ribbons were examined using X-ray diffraction, differential scanning calorimeter, and scanning electron microscope. Meanwhile, the hardness and surface roughness of these ribbons were measured by Vickers microhardness tester and atomic force microscope. The potentiodynamic polarization curves and electrochemical impedance spectroscopy (EIS) were applied to investigate the corrosion behavior of these MEAAC ribbons in simulated seawater (3.5wt% NaCl corrosive solution) at room temperature. The results demonstrate that AlNiLa MEAAC ribbons in the as-received state are mainly composed of amorphous phase and intermetallic compounds. The hardness values of all melt-spun ribbons are above 310 HV0.1. With the increase of Al content, the linear polarization resistances of four various AlNiLa MEAAC ribbons are negligibly different numerically. It is also found that Al45Ni27.5La27.5 MEAAC ribbons have the most positive corrosion potential and the smallest corrosion current density at the same time; hence it may be a kind of potential material for metal surface protection in harsh ocean environment.

Similar content being viewed by others

References

Jiang QT, Lu D Z, Wang N, et al. The Corrosion Behavior of Mg-Nd Binary Alloys in the Harsh Marine Environment[J]. J. Magn. Alloy., 2021, 9(1): 292–304

Zhang J, Kong DJ. Effect of Laser Remelting on Microstructure and Immersion Corrosion of Cold-sprayed Aluminum Coating on S355 Structural Steel[J]. Opt. Laser Technol., 2018, 106: 348–356

Lin JH, Dan ZH, Lu J F, et al. Research Status and Prospect on Marine Corrosion of Titanium Alloys in Deep Ocean Environments[J]. Rare Met. Mater. Eng., 2020, 49(3): 1 090–1 099

Zhang SY, Zhang ZB, Gao YY, et al. Research Progress in High-entropy Metallic Glasses: Comprehensive Properties and Composition Patterns Characteristics[J]. Rare Met. Mater. Eng., 2021, 50(6): 2 215–2 228

Zhang SY, Gao YY, Zhang ZB, et al. Research Progress in Corrosion Resistance of High-entropy Metallic Glasses[J]. Cailiao Gongcheng/J. Mater. Eng., 2021, 49(1): 44–54

Liu Q, Cheng JB, Zhang L, et al. Corrosion Behaviours of Arc-sprayed AlSi-based Amorphous/Nanocrystalline Coating[J]. Surf. Eng., 2021, 37(5): 606–617

Li GQ, Huang W, Li HX, et al. Corrosion Behavior of Mg-65Cu25-xZnxGd10 (x = 0, 5) Metallic Glass[J]. J.Wuhan Univ. Technol. -Mater. Sci. Ed., 2008, 23(5): 678–682

Yue LJ, Liu YL, **e K. Glass Forming Ability and Crystallization Kinetics of Cu-Zr-Al-(Y, Ag) Amorphous Alloy[J]. J. Wuhan Univ. Technol. -Mater. Sci. Ed., 2018, 33(4): 938–945

Yan XH, Zou Y, Zhang Y. Properties and Processing Technologies of High-entropy Alloys[J]. Mater. Futures, 2022, 1: 022002

Li JC, Huang YX, Meng XC, et al. A Review on High Entropy Alloys Coatings: Fabrication Processes and Property Assessment[J]. Adv. Eng. Mater., 2019, 21(8): 1 900 343

Cai ZH, Guo Y, Liu J, et al. Progress in Light-weight High Entropy Alloys[J]. J. Wuhan Univ. Technol. — Mater. Sci. Ed., 2021, 36(5): 737–753

Shi Y, Yang B, Liaw P. Corrosion-resistant High-entropy Alloys: A Review[J]. Metals, 2017, 7(2): 43

Fu Y, Li J, Luo H, et al. Recent Advances on Environmental Corrosion Behavior and Mechanism of High-entropy Alloys[J]. J. Mater. Sci. Technol., 2021, 80: 217–233

Liang YF, Wang S, Li H, et al. Fabrication of Fe-6.5wt% Si Ribbons by Melt Spinning Method on Large Scale[J]. Adv Mater Sci Eng., 2015, 2015: 296 197

Wang WH. High-entropy Metallic Glasses[J]. JOM, 2014, 66(10): 2 067–2 077

Gong P, Li KR, Wang DL, et al. Research Progress in Zr-Ti Containing High-entropy Metallic Glasses (in Chinese)[J]. Chin. Sci. Bull., 2022, 67: 1 103–1 118

Xue L, Shao LL, Luo Q, et al. Gd25RE25Co25Al25 (RE = Tb, Dy and Ho) High-entropy Glassy Alloys with Distinct Spin-glass Behavior and Good Magnetocaloric Effect[J]. J. Alloy. Compd., 2019, 790: 633–639

Nayak S K, Kumar A, Sarkar K, et al. Mechanistic Insight into the Role of Amorphicity and Porosity on Determining the Corrosion Mitigation Behavior of Fe-based Amorphous/Nanocrystalline Coating[J]. J. Alloy. Compd., 2020, 849: 156 624

Yang ZZ, Jiang SS, Ye LX, et al. Nanoscale Structural Heterogeneity Perspective on the Ameliorated Magnetic Properties of a Fe-based Amorphous Alloy with Decreasing Cooling Rate[J]. J. Non-Cryst. Solids., 2022, 581: 121 433

Zhang SY, Zhang ZB, Gao YY, et al. Microstructure and Corrosion Property of Equiatomic AlNiZrCuY High Entropy Amorphous Composite Material[J]. Rare Met. Mater. Eng., 2022, 51(2): 698–704

Abbas QA, Morley NA. Fabrication and Characterization of Magnetostrictive Amorphous FeGaSiB Thin Films[J]. J. Magn. Magn. Mater., 2017, 439: 353–357

Cui HB, Zhang MC, Wang Y, et al. Preparation of YbCu and YbCuAl Amorphous Films by Magnetron Co-sputtering[J]. Rare Met. Mater. Eng., 2022, 51(3): 1 040–1 046

Gögebakan M, Uzun O. Thermal Stability and Mechanical Properties of Al-based Amorphous Alloys[J]. J. Mater. Process. Tech., 2004, 153–154: 829–832

Yang BJ, Yao JH, Zhang J, et al. Al-rich Bulk Metallic Glasses with Plasticity and Ultrahigh Specific Strength[J]. Scr. Mater., 2009, 61: 423–426

Mansouri M, Varahram N, Simchi A. Effect of Copper on the Thermal Stability and Non-isothermal Crystallization Behavior of Al-86Ni10-xCuxRE4 (x = 0.5–2.5) Amorphous Alloys Prepared by Melt Spinning[J]. J. Non-Cryst. Solids., 2019, 506: 46–50

Inoue A, Zhang T. Thermal Stability and Glass-forming Ability of Amorphous Nd-Al-TM (TM = Fe, Co, Ni or Cu) Alloys[J]. Mater. Sci. Eng., A, 1997, 226–228: 393–396

Zhao SF, Wang HB, **ao L, et al. High Strain Rate Sensitivity of Hardness in Quinary Ti-Zr-Hf-Cu-Ni High Entropy Metallic Glass Thin Films[J]. Physica E., 2017, 94: 100–105

Chen HX, Kong DJ. Comparison on Electrochemical Corrosion Performances of Arc and Laser Thermal Sprayed Al-Ti-Ni Coatings in Marine Environment[J]. Mater. Chem. Phys., 2020, 251: 123 200

Gao MH, Lu WY, Yang BJ, et al. High Corrosion and Wear Resistance of Al-based Amorphous Metallic Coating Synthesized by HVAF Spraying[J]. J. Alloy. Compd., 2018, 735: 1 363–1 373

Wei L, Liu Y, Li Q, et al. Effect of Roughness on General Corrosion and Pitting of (FeCoCrNi)0.89(WC)0.11 High-entropy Alloy Composite in 3.5wt% NaCl Solution[J]. Corros. Sci., 2019, 146: 44–57

Zhang LM, Zhang SD, Ma AL, et al. Thermally Induced Structure Evolution on the Corrosion Behavior of Al-Ni-Y Amorphous Alloys[J]. Corros. Sci., 2018, 144: 172–183

Wang Z, Feng Z, Zhang L, et al. Current Application and Development Trend in Electrochemical Measurement Methods for the Corrosion Study of Stainless Steels[J]. Gongcheng Kexue Xuebao/Chin. J. Eng., 2020, 42(5): 549–556

Li XW, Wang HX, Shi T, et al. Efficient Preparation and Anticorrosion Mechanism of Superhydrophobic 7075 Aviation Aluminum Alloy[J]. Rare Met. Mater. Eng., 2022, 51(1): 6–10

Wang PP, Jiang HT, Wang YJ, et al. Improvement of Hot Workability and Corrosion Resistance of Mg-3AI-1Zn-0.1Mn-0.2Ca Alloy Through Hot Deformation[J]. Rare Met. Mater. Eng., 2021, 50(6): 1 910–1 918

Zhang SY, Zhang ZB, Gao YY, et al. Effect of Copper Content on Glass-forming Ability and Corrosion Resistance of Novel AlNiZrCoY-Si High Entropy Amorphous Alloy[J]. Rare Met. Mater. Eng., 2021, 50(12): 4 587–4 591

Zhang YA, Gao XF, Liang XB, et al. Effect of Laser Remelting on the Microstructure and Corrosion Property of the Arc-sprayed AlFeNbNi Coatings[J]. Surf. Coat. Technol., 2020, 398: 126 099

Zhang SY, Zhang ZB, He PF, et al. Role of Co Content on the Microstructure and Anti-corrosion Performance of High-hardness AlNiYCox High Entropy Metallic Glasses[J]. J. Non-Cryst. Solids, 2022, 576: 121 268

Ge YY, Cheng JB, Wang XY, et al. Formation and Properties of Superhydrophobic Al Coatings on Steel[J]. ACS Omega, 2021, 6(28): 18 383–18 394

Acknowledgements

This work is supported by the National Key R&D Program of China (No. 2018YFC1902400) and the National Natural Science Foundation of China (No. 51975582). TEM characterization was provided using the equipment of the eceshi (u]www.eceshi.com), and the authors are very grateful for Dr. Xu from the eceshi. The authors would also like to thank Cheng Haowan, Ma Qiannan and Wei Feng from Shiyanjia Lab (u]www.shiyanjia.com) for the XRD, AFM, and SEM characterization tests.

Funding

Funded by the National Key R&D Program of China (No. 2018YFC1902400), the National Natural Science Foundation of China (No. 51975582) and the Natural Science Foundation of Bei**g, China (No.2212055)

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Zhang, S., Zhang, Z., Gao, Y. et al. Microstructure and Corrosion Resistance of a Novel AlNiLa Lightweight Medium Entropy Amorphous Alloy Composites. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 37, 1185–1191 (2022). https://doi.org/10.1007/s11595-022-2651-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-022-2651-7