Abstract

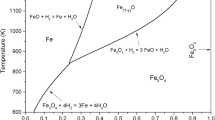

Ferrum niobate was synthesized by solid-phase sintering method in a vacuum carbon tube furnace at 1 300 °C for 180 min. The phase transformation of ferrum niobate carbothermal reduction process was studied by XRD. The reduction reactions of ferrum niobate in different temperature stages were determined by the TG-DSC curve. Meanwhile, according to the TG curve, the reaction kinetics parameters were calculated by A.W.Coats integration and the control steps in different temperature stages were ascertained. The results showed that the reduction of ferrum niobate starts at the temperature of 1 000 °C, and the reduction process carries out in two steps according to sintering temperature.In a temperature range of 1 000-1 238 °C (the first step), the main reduction products are NbO2 and Fe; the kinetic equation of initial stage is [-ln(1-α)]4=kt, controlled by nucleation growth, and the apparent activation energy is 388 kJ/mol; with the temperature increasing, the kinetic equation is α+(1-α)ln(1-α)=kt, which is the Valensi two-dimensional diffusion kinetic equation, and the apparent activation energy is 264.4 kJ/mol. The main reaction in a range of 1 238-1 344 °C(the second step) is the reduction of NbO2 to NbC, the kinetic equation is [(1-α)-1/3-1]2=kt, which is controlled by the three-dimensional diffusion, and the apparent activation energy is 482.7 kJ/mol.

Similar content being viewed by others

References

Yu Y F. The Research on Comprehensive Utilization of Rare Earth and Niobium Resources in BayanObo Ore Is of Great Significance [J]. Rare Earth Information, 2007 (8): 8–9

Lin D L, Li C L, Wu H L. Technological Breakthrough and Progress on BayanObo Special Ore Mining [M]. Bei**g: Metallurgical Industry Press, 2007

He X C, Fan P, Yang T J. Research on Improving the Niobium Recovery of Blast Furnace Smelting Iron Ore Contained with Niobium [J]. Hunan Metallurgy, 1990 (4): 1–4

He X C, Yang Y Y, Dong Y C. Research on the Process of Niobium Entering into Iron Phase in the Smelting Reduction Stage of Niobiumenriched Furnace Burden [J]. Hunan Metallurgy, 1994 (5): 8–12

Shinichi Ito. Synthesis of Tantalum-niobium Minerals and Mineral Processing Properties [J]. Foreign Rare Metals, 1986 (2): 33–36

E T Turkdogan. Physical Chemistry of High Temperature Technology [M]. New York: Academic Press, 1980

Li Y Z. Thermoanalysis [M]. Bei**g: Tsinghua University Press, 1987

Hu R Z, Shi Q Z. Thermoanalysis Kinetics [M]. Bei**g: Science Press, 2001

Guo H J. Metallurgical Physical Chemistry Tutorial [M]. Bei**g: Metallurgical Industry Press, 2004

Sanchez-ramos, S domenech-carbo, A Gimeno-Adelantado. Thermal Decomposition of Chromite Spinel with Chlorite Admixture [J]. Thermochim. Acta, 2008, 476(1):11–19

Author information

Authors and Affiliations

Corresponding author

Additional information

Funded by National Natural Science Foundation of China (No.50974073), Inner Mongolia Natural Science Foundation (No.2012MS0714), Significant Special Fund of Inner Mongolia Science & Technology Department and National Key Laboratory of Inner Mongolia University of Science and Technology Foundation (No. BO-13-001)

Rights and permissions

About this article

Cite this article

Li, J., Li, B., Yang, Y. et al. Kinetic mechanism in the process of carbothermal reduction of ferrum niobate. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 30, 918–922 (2015). https://doi.org/10.1007/s11595-015-1250-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-015-1250-2