Abstract

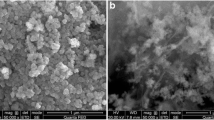

Three-dimensional (3D) five-directional braided (SiO2) f /SiO2 composites were prepared by silicasol-infiltration-sintering (SIS) method. The flexural properties and microstructures were studied. The flexural strength and flexural elastic modulus were found to be 73 MPa and 12 GPa, respectively. The results of stress vs deflection curve and SEM examinations revealed that the fracture mechanism of 3D, five-directional braided (SiO2) f /SiO2 composite was a mixture mode of ductile and brittle. The ductile mode was attributed to the weak bonding strength of fiber/matrix at low temperature. The brittle fracture might be caused by the propagation of micro defect or crack, which existed in the as-prepared composites for the ten-cycle process.

Similar content being viewed by others

References

Ortiz-Longo CR, White KW. Elevated-Temperature Fracture Characterization of Advanced Fibrous Ceramic Thermal Insulators [J]. J. Am. Ceram. Soc., 1994, 77: 2 703–2 711

Chen ZF, Zhang LT, Cheng LF, et al. Effect of CVI Temperature on the microstructure of Nextel 480/SiO2 [J]. Science and Engineering of Composites Materials, 2003, 10: 403–406

Wang YG, Liu JL. Aluminum Phosphate-mullite Composites for Hightemperature Radome Applications [J]. International Journal of Applied Ceramic Technology, 2009, 6: 190–194

Prasad NE, Loidl D, Vijayakumar M, et al. Elastic Properties of Silica-Silica Continuous Fibre-reinforced Ceramic Matrix Composites[J]. Scripta Mater., 2004, 50: 1 121–1 126

Meyer FP, Quinn GD, Walck JC. Reinforcing Fused Silica with High Purity Fibres [J]. Ceram. Sci. Eng. Soc. Proc., 1985, 6: 646–656

Misha S, Mitra R, Vijayakumar M. Structure and Properties of Short Fibre Reinforced Silica Matrix Composite Foams[J]. Ceramics Internatioanl, 2009, 35: 3 111–3 116

Xu CM, Wang SW, Huang XX, et al. Processing and Properties of Unidirectional (SiO2)f/SiO2 Composites [J]. Ceramics International, 2007, 33: 669–673

Han S, Jiang KH, Tang JW. Studied on Preparation and Property of 2.5D (SiO2)f/SiO2 Composites [J]. Advanced Materials Research, 2009, 79–82: 1 767–1 770

Choy KL, Duplock P, Rogers PS, et al The Mechanical Behavior of Glass and Glass-ceramic Mmatrix Composites[J]. Materials Science and Engineering A, 2009, 278: 187–194

Xu K, Xu XW. Finite Element Analysis of Mechanical Properties of 3D Five-directional Braided Composites[J]. Materials Science and Engineering A, 2008, 487: 400–509

Chen H, Zhang LM, Hu LM, et al. Flexural Properties of 3D-SiO2/SiO2 Composites [J]. Key Engineering Materials, 2003, 249: 163–166

Ochiai S, Murakami Y. Tensile Strength of Composites with Brittle Reaction Zones at Interfaces [J]. Journal of Materials Science, 1979, 14: 831–840

Naslain RR. The Design of the Fibre-matrix Interfacial Zone in Ceramic Matrix Composites Composites[J]. Part A: Applied Science and Manufacturing, 1998, 29: 1 145–1 155

Author information

Authors and Affiliations

Corresponding author

Additional information

Funded by the Basic Research Project of Science and Technology of Jiangsu Province (No.BK2009002), the National Natural Science Foundation of China (No.61176062) and the Fundamental Research Funds for the Central Universities (No.NS2013061)

Rights and permissions

About this article

Cite this article

Li, B., Zhu, J., Lin, L. et al. Fracture mechanism of 3D, five-directional braided (SiO2) f /SiO2 composites prepared by silicasol-infiltration-sintering method. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 28, 355–357 (2013). https://doi.org/10.1007/s11595-013-0694-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-013-0694-5