Abstract

Silicon is a strong competitor for the anode of the next generation of lithium-ion batteries, and ball-milled silicon has broad prospects as a low-cost method for preparing nano silicon. In order to match ball-milled silicon, it is imperative to develop better bonding agents with lower costs. Through adding amino silane coupling agent, the performance of ball-milling silicon anode is enhanced. This study explored the network structure formed by amino silane coupling agent with different chain lengths and polyacrylic acids. Herein, the crosslinked network prepared with 3-[2-(2-aminoethyl amino) ethyl amino] propyl-trimethoxysilane as coupling agent had the best performance, and the initial discharge capacity of the silicon anode prepared by this binder reached 3297.4 mAh·g−1 at a constant current density of 0.5A·g−1, the initial Coulomb efficiency reached 92.25%. After 100 cycles, the discharge capacity of anode was still maintained at 2229.5 mAh·g−1 with excellent charge/discharge performance.

Similar content being viewed by others

Data availability

The data and materials that support the findings of this study are available from the corresponding author upon reasonable request.

References

Liu Y, Shao R, Jiang R, Song X, ** Z, Sun L (2023) A review of existing and emerging binders for silicon anodic Li-ion batteries. Nano Res 16:6736–6752

Lu J, Wu TP, Amine K (2017) State-of-the-art characterization techniques for advanced lithium-ion batteries. Nat Energy 2:3

Eshetu GG, Zhang H, Judez X, Adenusi H, Armand M, Passerini S et al (2021) Production of high-energy Li-ion batteries comprising silicon-containing anodes and insertion-type cathodes. Nat Commun 12:1

Zhao HS, Qi YL, Liang K, Zhu WK, Wu HB, Li JB et al (2022) Phosphorus-do** and oxygen vacancy endowing anatase TiO with excellent sodium storage performance. Rare Metals 4:1284–1293

Deng R, Wang Z, Chen K (2023) Dual function high efficiency silicon electrode prelithiation strategy. Ionics 29:2241–2248

He XM, Pu WH, Ren JG, Wang L, Jiang CY, Wan CR (2007) Synthesis of nanosized Si composite anode material for Li-ion batteries. Ionics 13:51–54

Ryu J, Song WJ, Lee S, Choi S, Park S (2020) A game changer: functional nano/micromaterials for smart rechargeable batteries. Adv Funct Mater 30:2

Chen ZD, Soltani A, Chen YG, Zhang QB, Davoodi A, Hosseinpour S et al (2022) Emerging organic surface chemistry for Si anodes in lithium-ion batteries: advances, prospects, and beyond. Adv Energy Mater 12:32

Arano K, Begic S, Chen FF, Rakov D, Mazouzi D, Gautier N et al (2021) Tuning the formation and structure of the silicon electrode/ionic liquid electrolyte interphase in superconcentrated ionic liquids. ACS Appl Mater Interfaces 13:28281–28294

Chen J, Fan XL, Li Q, Yang HB, Khoshi MR, Xu YB et al (2020) Electrolyte design for LiF-rich solid-electrolyte interfaces to enable high-performance microsized alloy anodes for batteries. Nat Energy 5:386–397

Hu MF, Wu HZ, Zhang GJ (2023) High-performance silicon/graphite anode prepared by CVD using SiCl4 as precursor for Li-ion batteries. Chem Phys Lett 833:140917

Hu LB, Wu H, Hong SS, Cui LF, McDonough JR, Bohy S et al (2011) Si nanoparticle-decorated Si nanowire networks for Li-ion battery anodes. Chem Commun 47:367–369

Tesfaye AT, Gonzalez R, Coffer JL, Djenizian T (2015) Porous silicon nanotube arrays as anode material for Li-Ion batteries. ACS Appl Mater Interfaces 7:20495–20498

Lu WJ, Guo XT, Luo YQ, Li Q, Zhu RM, Pang H (2019) Core-shell materials for advanced batteries. Chem Eng J 355:208–237

Qi J, Yu X, Chen B, Zhuo H, Chen S (2023) Enhanced cycling stability and rate capability of silicon/graphite anodes by chitosan-based aqueous binder. Ionics 29:951–961

Zhao H, Li J, Ren Y (2024) Regulation of lithium ion transport in Si/C anodes by piezoelectric effect. Sci Sin Chimica 54(3):385–395

Zhao HS, Liang K, Wang SJ, Ding ZP, Huang XB, Chen WK et al (2023) A stress self-adaptive silicon/carbon “ordered structures” to suppress the electro-chemo-mechanical failure: piezo-electrochemistry and piezo-ionic dynamics. Adv Sci 10:29

Gauthier M, Reyter D, Mazouzi D, Moreau P, Guyomard D, Lestriez B et al (2014) From Si wafers to cheap and efficient Si electrodes for Li-ion batteries. J Power Sources 256:32–36

Li HD, Li HY, Lai YZ, Yang ZW, Yang Q, Liu Y et al (2022) Revisiting the preparation progress of nano-structured Si anodes toward industrial application from the perspective of cost and scalability. Adv Energy Mater 12:7

You R, Han X, Zhang Z, Li L, Li C, Huang W et al (2019) An environmental friendly cross-linked polysaccharide binder for silicon anode in lithium-ion batteries. Ionics 25:4109–4118

Hwang JH, Kim E, Lim EY, Lee WH, Kim JO, Choi I et al (2023) A multifunctional interlocked binder with synergistic in situ covalent and hydrogen bonding for high-performance Si anode in Li-ion batteries. Adv Sci 10:30

Liu J, Zhang Q, Wu ZY, Wu JH, Li JT, Huang L et al (2014) A high-performance alginate hydrogel binder for the Si/C anode of a Li-ion battery. Chem Commun 50:6386–6389

Zhao XY, Niketic S, Yim CH, Zhou JG, Wang J, Abu-Lebdeh Y (2018) Revealing the role of poly(vinylidene fluoride) binder in Si/graphite composite anode for Li-Ion batteries. ACS Omega 3:11684–11690

Wei CX, Obrovac MN (2019) Small molecule slurry additives for Si alloy coatings with CMC/SBR binder. J Electrochem Soc 166:A3217–A3221

Buqa H, Holzapfel M, Krumeich F, Veit C, Novák P (2006) Study of styrene butadiene rubber and sodium methyl cellulose as binder for negative electrodes in lithium-ion batteries. J Power Sources 161:617–622

Hu YY, You JH, Zhang SJ, Lin H, Ren WF, Deng L et al (2021) Li PAA domains filled in porous sodium alginate skeleton: a 3D bicontinuous composite network binder to stabilize micro-silicon anode for high-performance lithium ion battery. Electrochim Acta 386:138361

Li S, Wu ZG, Liu YM, Yang ZW, Wang GK, Liu YX et al (2021) A compared investigation of different biogum polymer binders for silicon anode of lithium-ion batteries. Ionics 27:1829–1836

Magasinski A, Zdyrko B, Kovalenko I, Hertzberg B, Burtovyy R, Huebner CF et al (2010) Toward efficient binders for Li-Ion battery Si-based anodes: polyacrylic acid. ACS Appl Mater Interfaces 2:3004–3010

Jung C-H, Kim K-H, Hong S-H (2019) Stable silicon anode for lithium-ion batteries through covalent bond formation with a binder via esterification. ACS Appl Mater Interfaces 11:26753–26763

Bie Y, Yang J, Lu W, Lei Z, Nuli Y, Wang J (2016) A facile 3D binding approach for high Si loading anodes. Electrochim Acta 212:141–146

** H, Chen Q, Wu SS, Shen J (2012) Effect of length of branched-chain of PAA-g-MPEO on dispersion of CaCO aqueous suspensions. Polym Bull 68:597–605

Liang J, Fan Z, Chen S, Zheng S, Wang Z (2021) A novel three-dimensional cross-linked net structure of submicron Si as high-performance anode for LIBs. J Alloys Compd 860:158433

Ma TY, Xu HY, Yu XN, Li HY, Zhang WG, Cheng XL et al (2019) Lithiation behavior of coaxial hollow nanocables of carbon-silicon composite. ACS Nano 13:2274–2280

Dong JM, Li Y, Wen J, **ao XY, Zhu XL, Man YY (2020) Research on hydrolysis process of KH550 silane coupling agent. J Salt Lake Res 28:28–33

Author information

Authors and Affiliations

Contributions

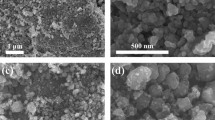

ZY. T. wrote the main manuscript text. ZL. W. prepared figures 1-4. ZC. L. prepared figures 5-7. KH. C. came up with the idea. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Ethics approval

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Teng, Z., Wang, Z., Li, Z. et al. Study on modification of different amino silanes modified polyacrylic acid for ball milling silicon anode of lithium-ion batteries. Ionics 30, 3111–3119 (2024). https://doi.org/10.1007/s11581-024-05497-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11581-024-05497-2