Abstract

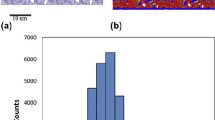

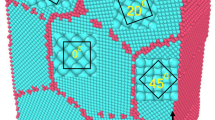

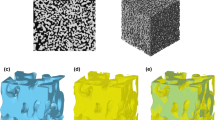

A series of large-scale molecular dynamics (MD) simulations has been performed to study the effects of grain size and ligament diameter on the mechanical properties of nanocrystalline nanoporous gold. Such simulations indicate that the principal deformation mechanism is a combination of grain boundary sliding, grain rotation and dislocation movement. The results of uniaxial tensile tests reveal the presence of a reverse Hall-Petch relation between strength and nominal grain size, rather than the conventional Hall-Petch relationship in the present range of nominal grain size (7.9–52.7 nm). An increase of flow stress may possibly attribute to the lower total proportion of grain boundary sliding and grain rotation in the deformation of samples with larger grain size. The Young’s modulus shows a linear relation with the reciprocal of nominal grain size, which depends largely on the volume fraction of grain boundaries and thus decreasing grain size leads to relatively lower Young’s modulus. MD simulations on samples with ligament diameter ranging from 4.07 to 8.10 nm are also carried out and results show that the increasing ligament diameter resulted in decreased flow stress and increased Young’s modulus.

Similar content being viewed by others

References

Wittstock A, Zielasek V, Biener J, et al. Nanoporous gold catalysts for selective gas-phase oxidative coupling of methanol at low temperature. Science, 2010, 327: 319–322

Ding Y, Zhang Z. Nanoporous Metals for Advanced Energy Technologies. Berlin: Springer Cham, 2016. 83–131

Zhang L, Chang H, Hirata A, et al. Nanoporous gold based optical sensor for sub-ppt detection of mercury ions. ACS Nano, 2013, 7: 4595–4600

Biener J, Wittstock A, Zepeda-Ruiz L A, et al. Surface-chemistrydriven actuation in nanoporous gold. Nat Mater, 2009, 8: 47–51

Sun S, Chen X, Badwe N, et al. Potential-dependent dynamic fracture of nanoporous gold. Nat Mater, 2015, 14: 894–898

Vega A A, Newman R C. Nanoporous metals fabricated through electrochemical dealloying of Ag-Au-Pt with systematic variation of Au:Pt ratio. J Electrochem Soc, 2013, 161: C1–C10

Mameka N, Wang K, Markmann J, et al. Nanoporous gold-testing macro-scale samples to probe small-scale mechanical behavior. Mater Res Lett, 2015, 4: 27–36

Gibson L J, Ashby M F. Cellular Solids: Structure and Properties. 2nd ed. Cambridge: Cambridge University Press. 1997

**a R, Feng X Q, Wang G F. Effective elastic properties of nanoporous materials with hierarchical structure. Acta Mater, 2011, 59: 6801–6808

Chen Q, Pugno N M. Mechanics of hierarchical 3-D nanofoams. Europhys Lett, 2012, 97: 26002

Biener J, Hodge A M, Hayes J R, et al. Size effects on the mechanical behavior of nanoporous Au. Nano Lett, 2006, 6: 2379–2382

Fu E G, Caro M, Zepeda-Ruiz L A, et al. Surface effects on the radiation response of nanoporous Au foams. Appl Phys Lett, 2012, 101: 191607

Zhang Z, Wang Y, Qi Z, et al. Generalized fabrication of nanoporous metals (Au, Pd, Pt, Ag, and Cu) through chemical dealloying. J Phys Chem C, 2009, 113: 12629–12636

Yu J, Ding Y, Xu C, et al. Nanoporous metals by dealloying multicomponent metallic glasses. Chem Mater, 2008, 20: 4548–4550

Dou R, Xu B, Derby B. High-strength nanoporous silver produced by inkjet printing. Scripta Mater, 2010, 63: 308–311

Qi Z, Zhao C, Wang X, et al. Formation and characterization of monolithic nanoporous copper by chemical dealloying of Al-Cu alloys. J Phys Chem C, 2009, 113: 6694–6698

Schiøtz J, Di Tolla F D, Jacobsen K W. Softening of nanocrystalline metals at very small grain sizes. Nature, 1998, 391: 561–563

Dao M, Lu L, Asaro R, et al. Toward a quantitative understanding of mechanical behavior of nanocrystalline metals. Acta Mater, 2007, 55: 4041–4065

Rottmann P F, Hemker K J. Experimental quantification of mechanically induced boundary migration in nanocrystalline copper films. Acta Mater, 2017, 140: 46–55

Meyers M A, Mishra A, Benson D J. Mechanical properties of nanocrystalline materials. Prog Mater Sci, 2006, 51: 427–556

Chokshi A H, Rosen A, Karch J, et al. On the validity of the hall-petch relationship in nanocrystalline materials. Scripta Metall, 1989, 23: 1679–1683

Nieh T G, Wadsworth J. Hall-petch relation in nanocrystalline solids. Scripta Metall Mater, 1991, 25: 955–958

Sun X Y, Xu G K, Li X, et al. Mechanical properties and scaling laws of nanoporous gold. J Appl Phys, 2013, 113: 023505

Rida A, Rouhaud E, Makke A, et al. Study of the effects of grain size on the mechanical properties of nanocrystalline copper using molecular dynamics simulation with initial realistic samples. Philos Mag, 2017, 97: 2387–2405

Zhang T, Zhou K, Chen Z Q. Strain rate effect on plastic deformation of nanocrystalline copper investigated by molecular dynamics. Mater Sci Eng-A, 2015, 648: 23–30

Zhou K, Liu B, Yao Y, et al. Effects of grain size and shape on mechanical properties of nanocrystalline copper investigated by molecular dynamics. Mater Sci Eng-A, 2014, 615: 92–97

**an Y, Li J, Wu R, et al. Softening of nanocrystalline nanoporous platinum: A molecular dynamics simulation. Comput Mater Sci, 2018, 143: 163–169

Newman R C, Corcoran S G, Erlebacher J, et al. Alloy crrosion. MRS Bull, 1999, 24: 24–28

Cahn J W, Hilliard J E. Free energy of a nonuniform system. I. Interfacial free energy. J Chem Phys, 1958, 28: 258–267

Mäder U, Mader U. Chord length distributions for circular cylinders. Radiat Res, 1980, 82: 454–466

Plimpton S. Fast parallel algorithms for short-range molecular dynamics. J Comput Phys, 1995, 117: 1–19

Daw M S, Baskes M I. Embedded-atom method: Derivation and application to impurities, surfaces, and other defects in metals. Phys Rev B, 1984, 29: 6443–6453

Stukowski A. Visualization and analysis of atomistic simulation data with OVITO—The open visualization tool. Model Simul Mater Sci Eng, 2010, 18: 015012

Tsuzuki H, Branicio P S, Rino J P. Structural characterization of deformed crystals by analysis of common atomic neighborhood. Comput Phys Commun, 2007, 177: 518–523

Yildiz Y O, Kirca M. Atomistic simulation of Voronoi-based coated nanoporous metals. Model Simul Mater Sci Eng, 2017, 25: 025008

Subramaniyan A K, Sun C T. Continuum interpretation of Virial stress in molecular simulations. Int J Solids Struct, 2008, 45: 4340–4346

Zhu C, Liu X, Yu X, et al. A small-angle X-ray scattering study and molecular dynamics simulation of microvoid evolution during the tensile deformation of carbon fibers. Carbon, 2012, 50: 235–243

Morrow B H, Striolo A. Supported bimetallic Pt-Au nanoparticles: Structural features predicted by molecular dynamics simulations. Phys Rev B, 2010, 81: 155437

Shim J H, Lee B J, Cho Y W. Thermal stability of unsupported gold nanoparticle: A molecular dynamics study. Surf Sci, 2002, 512: 262–268

Van Swygenhoven H, Farkas D, Caro A. Grain-boundary structures in polycrystalline metals at the nanoscale. Phys Rev B, 2000, 62: 831–838

Farkas D, Frøseth A, Van Swygenhoven H. Grain boundary migration during room temperature deformation of nanocrystalline Ni. Scripta Mater, 2006, 55: 695–698

Gu X W, Loynachan C N, Wu Z, et al. Size-dependent deformation of nanocrystalline Pt nanopillars. Nano Lett, 2012, 12: 6385–6392

Yamakov V, Wolf D, Phillpot S R, et al. Deformation mechanism crossover and mechanical behaviour in nanocrystalline materials. Philos Mag Lett, 2003, 83: 385–393

Nan C W, Li X, Cai K, et al. Grain size-dependent elastic moduli of nanocrystals. J Mater Sci Lett, 1997, 17: 1917–1919

Sanders P G, Eastman J A, Weertman J R. Elastic and tensile behavior of nanocrystalline copper and palladium. Acta Mater, 1997, 45: 4019–4025

Gao G J J, Wang Y J, Ogata S. Studying the elastic properties of nanocrystalline copper using a model of randomly packed uniform grains. Comput Mater Sci, 2013, 79: 56–62

Li X, Gao H. Smaller and stronger. Nat Mater, 2016, 15: 373–374

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, J., **an, Y., Zhou, H. et al. Mechanical properties of nanocrystalline nanoporous gold complicated by variation of grain and ligament: A molecular dynamics simulation. Sci. China Technol. Sci. 61, 1353–1363 (2018). https://doi.org/10.1007/s11431-018-9270-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-018-9270-9