Abstract

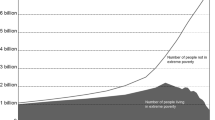

The strategy of carbon neutrality is resha** the global landscape of resource flow and recycling. As the final sink of geological minerals, the proliferated anthropogenic minerals, also called secondary resources, play an increasingly important role in resource supply enrichment. Niobium is a critical metal that lacks full concern for its sustainability. The fundamental principle of niobium circularity is to recycle and maintain the material as close to the manufacturing process as possible. Here we estimate the niobium-containing applications lost at their end-of-life, underscoring the imperative to minimize such disposal. Additionally, we elucidate the extraction processes for scrap and alloy quantities throughout the industry’s lifecycle. Drawing from anticipated waste generated by the majority of niobium applications, a forecast indicates a potential loss of approximately 168 kt by 2090 in the absence of recycling. Contrastingly, with a recycling efficiency of 90% for niobium, the projected loss diminishes to approximately 16 kt. We delve into the significance of niobium’s circular economy and explore various aspects that demand further investigation for a seamless transition from linear to circular practices.

Similar content being viewed by others

References

Alves A R, Coutinho A d R. 2015. The evolution of the niobium production in Brazil. Mat Res, 18: 106–112

Alves A R, Coutinho A d R. 2019. Life cycle assessment of niobium: A mining and production case study in Brazil. Miner Eng, 132: 275–283

Bakry M, Li J, Zeng X. 2023. Evaluation of global niobium flow modeling and its market forecasting. Front Energy, 17: 286–293

Broadbent C. 2016. Steel’s recyclability: Demonstrating the benefits of recycling steel to achieve a circular economy. Int J Life Cycle Assess, 21: 1658–1665

Charpentier Poncelet A, Helbig C, Loubet P, Beylot A, Muller S, Villeneuve J, Laratte B, Thorenz A, Tuma A, Sonnemann G. 2022. Losses and lifetimes of metals in the economy. Nat Sustain, 5: 717–726

Ciacci L, Reck B K, Nassar N T, Graedel T E. 2015. Lost by design. Environ Sci Technol, 49: 9443–9451

Ciacci L, Harper E M, Nassar N T, Reck B K, Graedel T E. 2016. Metal dissipation and inefficient recycling intensify climate forcing. Environ Sci Technol, 50: 11394–11402

Cullen J M, Allwood J M, Bambach M D. 2012. Map** the global flow of steel: From steelmaking to end-use goods. Environ Sci Technol, 46: 13048–13055

European C, Directorate-General for Internal Market I E, Smes, Bobba S, Carrara S, Huisman J, Mathieux F, Pavel C. 2020. Critical raw materials for strategic technologies and sectors in the EU—A foresight study (doi/https://doi.org/10.2873/58081): Publications Office

Freiin von Rennenberg T S. 2021. Towards a circular economy of critical raw materials: The case of niobium. Dissertation for Master’s Degree. Twente: University of Twente

Graedel T E, Allwood J, Birat J P, Buchert M, Hagelüken C, Reck B K, Sibley S F, Sonnemann G. 2011. What do we know about metal recycling rates? J Industrial Ecol, 15: 355–366

Graedel T E, Reck B K, Miatto A. 2022. Alloy information helps prioritize material criticality lists. Nat Commun, 13: 150

Hagelüken C, Goldmann D. 2022. Recycling and circular economy—Towards a closed loop for metals in emerging clean technologies. Miner Econ, 35: 539–562

Heisterkamp F, Carneiro T. 2011. Niobium: Future possibilities—Technology and the market place. Niobium, Science and Technology

IRP. 2024. Global Resources Outlook 2024: A report by the International Resource Panel. Nairobi, Kenya: United Nations Environment Programme

Klinkenberg C, Trute S, Bleck W. 2006. Niobium in engineering steels for automotive applications. Steel Res Int, 77: 698–703

Liang Z, Geng Y, Zhong C, **ao S, Wei W. 2024. Tracking the evolution of niobium cycle in China from 2000 to 2021: A dynamic material flow analysis. J Clean Prod, 434: 140455

McCaffrey D M, Nassar N T, Jowitt S M, Padilla A J, Bird L R. 2023. Embedded critical material flow: The case of niobium, the United States, and China. Resour Conserv Recycl, 188: 106698

Milan Grohol, Constanze Veeh. DG GROW, European Commission. 2023. European Commission, Study on the Critical Raw Materials for the EU 2023-Final Report

Mujkic Z, Krekhovetckii N, Kraslawski A. 2019. Material pinch location and critical materials recycling. Int J Manage Sustainability, 8: 10–19

Pan S, Zeng F, Su N, **an Z. 2020. The effect of niobium addition on the microstructure and properties of cast iron used in cylinder head. J Mater Res Tech, 9: 1509–1518

Rahimpour Golroudbary S, Krekhovetckii N, El Wali M, Kraslawski A. 2019. Environmental sustainability of niobium recycling: The case of the automotive industry. Recycling, 4: 5

Sovacool B K, Ali S H, Bazilian M, Radley B, Nemery B, Okatz J, Mulvaney D. 2020. Sustainable minerals and metals for a low-carbon future. Science, 367: 30–33

Sverdrup H U, Olafsdottir A H. 2023. Modelling the dynamics of the industrial vanadium cycle using the WORLD7 Integrated Assessment Model. Resources Environ Sustainability, 13: 100121

Tkaczyk A H, Bartl A, Amato A, Lapkovskis V, Petranikova M. 2018. Sustainability evaluation of essential critical raw materials: Cobalt, niobium, tungsten and rare earth elements. J Phys D-Appl Phys, 51: 203001

Tutton C G, Young S B, Habib K. 2022. Pre-processing of e-waste in Canada: Case of a facility responding to changing material composition. Resources Environ Sustainability, 9: 100069

Wang P, Wang H, Chen W Q, Pauliuk S. 2022. Carbon neutrality needs a circular metal-energy nexus. Fundamental Res, 2: 392–395

Zeng X. 2023. Win-Win: Anthropogenic circularity for metal criticality and carbon neutrality. Front Environ Sci Eng, 17: 23

Zeng X, Ogunseitan O A, Nakamura S, Suh S, Kral U, Li J, Geng Y. 2022a. Resha** global policies for circular economy. Circular Economy, 1: 100003

Zeng X, **ao T, Xu G, Albalghiti E, Shan G, Li J. 2022b. Comparing the costs and benefits ofvirgin and urban mining. J Manage Sci Eng, 7: 98–106

Zhu Y, Syndergaard K, Cooper D R. 2019. Map** the annual flow of steel in the United States. Environ Sci Technol, 53: 11260–11268

Acknowledgements

This study was supported by the National Natural Science Foundation of China (Grant Nos. 92062111 & 72394402).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest The authors declare that they have no conflict of interest.

Electronic supplementary material

Rights and permissions

About this article

Cite this article

Zeng, X., Gómez, M., Bakry, M. et al. Anthropogenic mineral generation and its potential resource supply: The case of niobium. Sci. China Earth Sci. (2024). https://doi.org/10.1007/s11430-023-1349-2

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11430-023-1349-2