Abstract

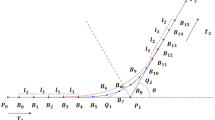

Previously, many studies have illustrated corner blend problem with different parameter curves. Only a few of them take a Pythagorean-hodograph (PH) curve as the transition arc, let alone corresponding real-time interpolation methods. In this paper, an integrated corner-transition mixing-interpolation-based scheme (ICMS) is proposed, considering transition error and machine tool kinematics. Firstly, the ICMS smooths the sharp corners in a linear path through blending the linear path with G3 continuous PH transition curves. To obtain optimal PH transition curves globally, the problem of corner smoothing is formulated as an optimization problem with constraints. In order to improve optimization efficiency, the transition error constraint is deduced analytically, so is the curvature extreme of each transition curve. After being blended with PH transition curves, a linear path has become a blend curve. Secondly, the ICMS adopts a novel mixed interpolator to process this kind of blend curves by considering machine tool kinematics. The mixed interpolator can not only implement jerk-limited feedrate scheduling with critical points detection, but also realize self-switching of two interpolation modes. Finally, two patterns are machined with a carving platform based on ICMS. Experimental results show the effectiveness of ICMS.

Similar content being viewed by others

References

Hu J, **ao L J, Wang Y H, et al., An optimal feedrate model and solution algorithm for a high-speed machine of small line blocks with look-ahead, Int. J. Adv. Manuf. Technol., 2006, 28: 930–935.

Dong J C, Wang T Y, Li B, et al., Smooth feedrate planning for continuous short line tool path with contour error constraint, International Journal of Machine Tools and Manufacture, 2014, 76: 1–12.

Zhang Q, Gao X S, Li H B, et al., Minimum time corner transition algorithm with confined feedrate and axial acceleration for nc machining along linear tool path, Int. J. Adv. Manuf. Technol., 2015, 89: 941–956.

Tajima S and Sencer B, Kinematic corner smoothing for high speed machine tools, International Journal of Machine Tools and Manufacture, 2016, 108: 27–43.

Duan M and Okwudire C, Minimum-time cornering for CNC machines using an optimal control method with NURBS parameterization, Int. J. Adv. Manuf. Technol., 2016, 85: 1405–1418.

Zheng W N, Bo P B, Liu Y, et al., Fast B-spline curve fitting by L-BFGS, Computer Aided Geometric Design, 2012, 29: 448–462.

Imre J and Ágoston R, Adjusting the energies of curves defined by control points, Computer-Aided Design, 2019, 107: 77–88.

Costa G, Montemurro M, and Pailhès J, A general hybrid optimization strategy for curve fitting in the non-uniform rational basis spline framework, J. Optim. Theory Appl., 2018, 176: 225–251.

Zhao H, Zhu L M, and Ding H, A parametric interpolator with minimal feed fluctuation for CNC machine tools using arc-length compensation and feedback correction, International Journal of Machine Tools and Manufacture, 2013, 75: 1–8.

Liu M, Huang Y, Yin L, et al., Development and implementation of a NURBS interpolator with smooth feedrate scheduling for CNC machine tools, International Journal of Machine Tools and Manufacture, 2014, 87: 1–15.

Lin F M, Shen L Y, Yuan C M, et al., Certified space curve fitting and trajectory planning for CNC machining with cubic B-splines, Computer-Aided Design, 2019, 106: 13–29.

Yang Z Y, Shen L Y, Yuan C M, et al., Curve fitting and optimal interpolation for CNC machining under confined error using quadratic B-splines, Computer-Aided Design, 2015, 66: 62–72.

Erkorkmaz K, Chen Q G, Zhao M Y, et al., Linear programming and windowing based feedrate optimization for spline toolpaths, CIRP Annals, 2017, 66: 393–396.

Guo J X, Zhang Q, Gao X S, et al., Time optimal feedrate generation with confined tracking error based on linear programming, Journal of Systems Science & Complexity, 2015, 28(1): 80–95.

Zhang K, Yuan C M, Gao X S, et al., A greedy algorithm for feedrate planning of CNC machines along curved tool paths with confined jerk, Robotics and Computer-Integrated Manufacturing, 2012, 28: 472–483.

Lin F M, Shen L Y, Yuan C M, et al., Certified space curve fitting and trajectory planning for cnc machining with cubic b-splines, Computer-Aided Design, 2019, 106: 13–29.

Erkorkmaz K, Yeung C, and Altintas Y, Virtual CNC system. Part II. High speed contouring application, International Journal of Machine Tools and Manufacture, 2006, 46: 1124–1138.

Ma L, Zhang C M, Zhang X, et al., Construction of G3 conic spline interpolation, Computer-Aided Design, 2016, 71: 15–27.

McCrae J and Singh K, Sketching piecewise clothoid curves, Computers and Graphics, 2009, 33: 452–461.

Pateloup V, Duc E, and Ray P, Bspline approximation of circle arc and straight line for pocket machining, Computer-Aided Design, 2010, 42: 817–827.

Ahmadi M and Mojallali H, Identification of multiple-input single-output Hammerstein models using Bezier curves and Bernstein polynomials, Applied Mathematical Modelling, 2011, 35: 1969–1982.

Zhao H, Zhu L M, and Ding H, A real-time look-ahead interpolation methodology with curvature-continuous B-spline transition scheme for CNC machining of short line segments, International Journal of Machine Tools and Manufacture, 2013, 65: 88–98.

Zhang Y, Ye P Q, Zhang H, et al., A local and analytical curvature-smooth method with jerk-continuous feedrate scheduling along linear toolpath, Int. J. Precis. Eng. Manuf., 2018, 19: 1529–1538.

Zhang Y, Zhao M Y, Ye P Q, et al., A G4 continuous B-spline transition algorithm for CNC machining with jerk-smooth feedrate scheduling along linear segments, Computer-Aided Design, 2019, 115: 231–243.

Popiel T and Noakes L, Bezier curves and C2 interpolation in Riemannian manifolds, Journal of Approximation Theory, 2007, 148: 111–127.

Fan W, Lee C H, and Chen J H, A realtime curvature-smooth interpolation scheme and motion planning for CNC machining of short line segments, International Journal of Machine Tools and Manufacture, 2015, 96: 27–46.

Fan W, Ji J W, Wu P Y, et al., Modeling and simulation of trajectory smoothing and feedrate scheduling for vibration-dam** CNC machining, Simulation Modelling Practice and Theory, 2020, 99: 102028.

Walton D and Meek D, Planar G2 transition with a fair pythagorean hodograph quintic curve, J. Comput. Appl. Math., 2002, 138: 109–126.

Walton D and Meek D, G2 blends of linear segments with cubics and Pythagorean-hodograph quintics, International Journal of Computer Mathematics, 2009, 86: 1498–1511.

Farouki R T, Construction of G2 rounded corners with Pythagorean-hodograph curves, Computer Aided Geometric Design, 2014, 31: 127–139.

Albrecht G, Beccari C V, and Romani L, Spatial Pythagorean-Hodograph B-spline curves and 3D point data interpolation, Computer Aided Geometric Design, 2020, 80: 101868.

Kim S H and Moon H P, Deformation of spatial septic Pythagorean hodograph curves using Gauss-Legendre polygon, Computer Aided Geometric Design, 2019, 73: 16–34.

Fan W, Gao X S, Yan W, et al., Interpolation of parametric CNC machining path under confined jounce, Int. J. Adv. Manuf. Technol., 2012, 62(5): 719–739.

Yuan C M, Zhang K, and Fan W, Time-optimal interpolation for CNC machining along curved tool pathes with confined chord error, Journal of Systems Science & Complexity, 2013, 26(5): 836–870.

Farouki R T and Neff C A, Hermite interpolation by Pythagorean Hodograph quintics, Mathematics of Computation, 1995, 64: 1589–1609.

Farouki R T, Pelosi F, and Sampoli M L, Optimization of corner blending curves, Computer-Aided Design, 2019, 117: 102739.

Zhang J L and Zhang X S, An sqp method based on smoothing penalty function for nonlinear optimization with inequality constraint, Journal of Systems Science & Complexity, 2001, 14(2): 212–217.

Zhao J B, Zhong B, Zou Q, et al., Tool orientation planning for five-axis CNC machining of open free-form surfaces, Journal of Systems Science & Complexity, 2013, 26(5): 667–675.

Zhou K, Wang G J, ** H Z, et al., NURBS interpolation based on exponential smoothing forecasting, Int. J. Adv. Manuf. Technol., 2008, 39: 1190–1196.

Zhao K, Li S R, and Kang Z J, Smooth minimum time trajectory planning with minimal feed fluctuation, Int. J. Adv. Manuf. Technol., 2019, 105: 1099–1111.

Author information

Authors and Affiliations

Corresponding author

Additional information

This research was supported by the National Natural Science Foundation of China under Grant No. 61573378; The authors also appreciate the supports from Henan Province Programs for Science and Technology Development under Grant No. 212102210391 and Anyang Institute of Technology Research and Cultivation Fund under Grant No. YPY2020012.

Rights and permissions

About this article

Cite this article

Zhao, K., Li, S. High Speed Machining for Linear Paths Blended with G3 Continuous Pythagorean-Hodograph Curves. J Syst Sci Complex 35, 1586–1607 (2022). https://doi.org/10.1007/s11424-022-0258-x

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11424-022-0258-x