Abstract

Background

The conventional isotropic elastic model neglects the anisotropy of sheet metals' elastic modulus, leading to inevitable errors in springback prediction.

Objective

Aiming at the problem of anisotropic springback in the forming process of sheet metals, an orthotropic elastic model was established in this study, and the applicability of the model was analyzed. An accurate and convenient numerical solution method was proposed, considering the challenge of calibrating model parameters through experimental measurement.

Methods

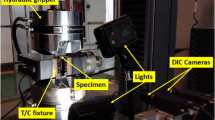

The reliability of the proposed parameter solution method is verified by uniaxial tensile and thin-walled tube torsion tests. To verify the anisotropic elastic model, both V-bending finite element simulation and experimental testing were conducted.

Results

The proposed parameter solution method has good prediction accuracy, with an average relative error within 5%. The three-group sample solution method significantly reduces experimental and data processing workload, demonstrating the precision and user-friendliness of this method. The proposed model yields a significant enhancement in springback prediction accuracy when compared to the conventional isotropic elastic model.

Conclusion

This study is basic research on the prediction of anisotropic springback, which can improve the simulation accuracy of the sheet metals forming process involving this problem, particularly in the anisotropic metal sheet stam** process.

Similar content being viewed by others

Data Availability

The authors confirm that the data supporting the findings of this study are available within the article.

References

Hou H, Zhao G, Chen L, Li H (2021) Anisotropic springback models of FCC metal material under severe plastic compressive deformation. Int J Mech Sci 202–203:106513. https://doi.org/10.1016/j.ijmecsci.2021.106513

Merklein M, Allwood JM, Behrens B-A, Brosius A, Hagenah H, Kuzman K, Mori K, Tekkaya AE, Weckenmann A (2012) Bulk forming of sheet metal. CIRP Ann 61(2):725–745. https://doi.org/10.1016/j.cirp.2012.05.007

Marko V, Miroslav H, Bojan S, Boris S (2011) A new anisotropic elasto-plastic model with degradation of elastic modulus for accurate springback simulations. IntJ Mater Form 4(2):217–225. https://doi.org/10.1007/s12289-011-1029-8

Yoshida F, Amaishi T (2020) Model for description of nonlinear unloading-reloading stress-strain response with special reference to plastic-strain dependent chord modulus. Int J Plast 130:102708. https://doi.org/10.1016/j.ijplas.2020.102708

Sun L, Wagoner RH (2011) Complex unloading behavior: Nature of the deformation and its consistent constitutive representation. Int J Plast 27(7):1126–1144. https://doi.org/10.1016/j.ijplas.2010.12.003

Zajkani A, Hajbarati H (2017) Investigation of the variable elastic unloading modulus coupled with nonlinear kinematic hardening in springback measuring of advanced high-strength steel in U-shaped process. J Manuf Process 25:391–401. https://doi.org/10.1016/j.jmapro.2016.12.022

Zajkani A, Hajbarati H (2017) An analytical modeling for springback prediction during U-bending process of advanced high-strength steels based on anisotropic nonlinear kinematic hardening model. Int J Adv Manuf Technol 90(1–4):349–359. https://doi.org/10.1007/s00170-016-9387-5

Meng Q, Zhai R, Zhang Y, Fu P, Zhao J (2022) Analysis of springback for multiple bending considering nonlinear unloading-reloading behavior, stress inheritance and Bauschinger effect. J Mater Process Technol 307:117657. https://doi.org/10.1016/j.jmatprotec.2022.117657

Chang Y, Wang N, Wang BT, Li XD, Wang CY, Zhao KM, Dong H (2021) Prediction of bending springback of the medium-Mn steel considering elastic modulus attenuation. J Manuf Process 67(8):345–355. https://doi.org/10.1016/j.jmapro.2021.04.074

Aerens R, Vorkov V, Duflou JR (2019) Springback prediction and elasticity modulus variation. in: 18th International Conference on Sheet Metal (SHEMET) - New Trends and Developments in Sheet Metal Processing, KU, Dept Mech Engn, Leuven, Belgium. 185–192. https://doi.org/10.1016/j.promfg.2019.02.125

Liu X, Cao J, Chai X, Liu J, Zhao R, Kong N (2017) Investigation of forming parameters on springback for ultra high strength steel considering Young’s modulus variation in cold roll forming. J Manuf Process 29:289–297. https://doi.org/10.1016/j.jmapro.2017.08.001

Yang X, Choi C, Sever NK, Altan T (2016) Prediction of springback in air-bending of Advanced High Strength steel (DP780) considering Young’s modulus variation and with a piecewise hardening function. Int J Mech Sci 105:266–272. https://doi.org/10.1016/j.ijmecsci.2015.11.028

Mehrabi H, Yang CH, Wang BL (2021) Investigation on springback behaviours of hexagonal close-packed sheet metals. Appl Math Model 92(9):149–175. https://doi.org/10.1016/j.jmapro.2017.08.001

Lin J, Hou Y, Min J, Tang H, Carsley JE, Stoughton TB (2020) Effect of constitutive model on springback prediction of MP980 and AA6022-T4. IntJ Mater Form 13(9):1–13. https://doi.org/10.1016/j.ijmecsci.2019.05.046

Hajbarati H, Zajkani A (2019) A novel analytical model to predict springback of DP780 steel based on modified Yoshida-Uemori two-surface hardening model. IntJ Mater Form 12(3):441–455. https://doi.org/10.1007/s12289-018-1427-2

Ul Hassan H, Traphoener H, Guener A, Tekkaya AE (2016) Accurate springback prediction in deep drawing using pre-strain based multiple cyclic stress-strain curves in finite element simulation. Int J Mech Sci 110:229–241. https://doi.org/10.1016/j.ijmecsci.2016.03.014

Yoshida F (2022) Description of elastic-plastic stress-strain transition in cyclic plasticity and its effect on springback prediction. IntJ Mater Form 15(2):12. https://doi.org/10.1007/s12289-022-01651-1

Seo KY, Kim JH, Lee HS, Kim JH, Kim BM (2018) Effect of Constitutive Equations on Springback Prediction Accuracy in the TRIP1180 Cold Stam**. Metals 8(1):18. https://doi.org/10.3390/met8010018

Meng Q, Zhao J, Mu Z, Zhai R, Yu G (2022) Springback prediction of multiple reciprocating bending based on different hardening models. J Manuf Process 76:251–263. https://doi.org/10.1016/j.jmapro.2022.01.070

Li Y, Liang Z, Zhang Z, Zou T, Li D, Ding S, **ao H, Shi L (2019) An analytical model for rapid prediction and compensation of springback for chain-die forming of an AHSS U-channel. Int J Mech Sci 159:195–212. https://doi.org/10.1016/j.ijmecsci.2019.05.046

Xue X, Liao J, Vincze G, Sousa J, Barlat F, Gracio J (2016) Modelling and sensitivity analysis of twist springback in deep drawing of dual-phase steel. Mater Des 90:204–217. https://doi.org/10.1016/j.matdes.2015.10.127

Hajbarati H, Zajkani A (2020) A novel finite element simulation of hot stam** process of DP780 steel based on the Chaboche thermomechanically hardening model. Int J Adv Manuf Technol 111:2705–2718. https://doi.org/10.1007/s00170-020-06297-4

Choi Y, Lee J, Panicker SS, ** HK, Panda SK, Lee MG (2020) Mechanical properties, springback, and formability of W-temper and peak aged 7075 aluminum alloy sheets: Experiments and modeling. Int J Mech Sci 170:105344. https://doi.org/10.1016/j.ijmecsci.2019.105344

Julsri W, Suranuntchai S, Uthaisangsuk V (2018) Study of springback effect of AHS steels using a microstructure based modeling. Int J Mech Sci 135:499–516. https://doi.org/10.9773/sosei.55.949

Sumikawa S, Ishiwatari A, Hiramoto J (2017) Improvement of springback prediction accuracy by considering nonlinear elastoplastic behavior after stress reversal. J Mater Process Technol 241:46–53. https://doi.org/10.1016/j.jmatprotec.2016.11.005

Sumikawa S, Ishiwatari A, Hiramoto J, Urabe T (2016) Improvement of springback prediction accuracy using material model considering elastoplastic anisotropy and Bauschinger effect. J Mater Process Technol 230:1–7. https://doi.org/10.1016/j.jmatprotec.2015.11.004

Leu DK (2019) Relationship between mechanical properties and geometric parameters to limitation condition of springback based on springback-radius concept in V-die bending process. Int J Adv Manuf Technol 101:913–926. https://doi.org/10.1007/s00170-018-2970-1

Zhu YX, Chen W, Li HP, Liu YL, Chen L (2018) Springback study of RDB of rectangular H96 tube. Int J Mech Sci 138:282–294. https://doi.org/10.1016/j.ijmecsci.2018.02.022

Ouakdi EH, Louahdi R, Khirani D, Tabourot L (2012) Evaluation of springback under the effect of holding force and die radius in a stretch bending test. Mater Des 35:106–112. https://doi.org/10.1016/j.matdes.2011.09.003

Zhai R, Ding X, Yu S, Wang C (2018) Stretch bending and springback of profile in the loading method of prebending and tension. Int J Mech Sci 144:746–764. https://doi.org/10.1016/j.ijmecsci.2018.06.028

Wang A, Xue H, Saud S, Yang Y, Wei Y (2019) Improvement of springback prediction accuracy for Z-section profiles in four-roll bending process considering neutral layer shift. J Manuf Process 48:218–227. https://doi.org/10.1016/j.jmapro.2019.11.008

Kut S, Stachowicz F, Pasowicz G (2021) Springback Prediction for Pure Moment Bending of Aluminum Alloy Square Tube. Materials 14(14):3814. https://doi.org/10.3390/ma14143814

Zhan M, **ng L, Gao PF, Ma F (2019) An analytical springback model for bending of welded tube considering the weld characteristics. Int J Mech Sci 150:594–609. https://doi.org/10.1016/j.ijmecsci.2018.10.060

Ailinei L, Galatanu SV, Marsavina L (2012) Influence of anisotropy on the cold bending of S600MC sheet metal. Eng Fail Anal 137:106206. https://doi.org/10.1016/j.engfailanal.2022.106206

Aleksandrović S, Ivković D, Arsic D, Дeлић M, Djačić S, Djordjevic MT (2023) Effect of plastic strain and specimen geometry on plastic strain ratio values for various materials. Adv Technol Mater 28(1):13–19. https://doi.org/10.24867/ATM-2023-1-003

Wu F, Hong Y, Zhang Z, Huang C, Huang Z (2023) Effect of Lankford Coefficients on Springback Behavior during Deep Drawing of Stainless Steel Cylinders. Materials 16(12):4321. https://doi.org/10.3390/ma16124321

Kut S, Pasowicz G, Stachowicz F (2023) On the Springback and Load in Three-Point Air Bending of the AW-2024 Aluminium Alloy Sheet with AW-1050A Aluminium Cladding. Materials 16(8):2945. https://doi.org/10.3390/ma16082945

Miksza M, Bohdal L, Kaldunski P, Patyk R, Leon K (2022) Forecasting the Fatigue Strength of DC01 Cold-Formed Angles Using the Anisotropic Barlat Model. Materials 15(23):8436. https://doi.org/10.3390/ma15238436

Aretz H (2005) A non-quadratic plane stress yield function for orthotropic sheet metals. J Mater Process Technol 168(1):1–9. https://doi.org/10.1016/j.jmatprotec.2004.10.008

Tong W, Alharbi M, Sheng J (2020) On the new shear constraint for plane-stress orthotropic plasticity modeling of sheet metals. Exp Mech 60(7):889–905. https://doi.org/10.1007/s11340-020-00596-3

Yin Q, Soyarslan C, Güner A, Brosius A, Tekkaya AE (2012) A cyclic twin bridge shear test for the identification of kinematic hardening parameters. Int J Mech Sci 59(1):31–43. https://doi.org/10.1016/j.ijmecsci.2012.02.008

Ballo F, Gobbi M, Mastinu G, Previati G (2020) Thin-walled tubes under torsion: multi-objective optimal design. Optim Eng 21:1–24. https://doi.org/10.1007/s11081-019-09431-8

Bhaduri A (2018) Torsion—Pure Shear. In: Mechanical Properties and Working of Metals and Alloys. Springer Singapore. 264:197–225. https://doi.org/10.1007/978-981-10-7209-3_5

Bailey JA, Haas SL, Nawab KC (1972) Anisotropy in Plastic Torsion. J Basic Eng 94:231–237. https://doi.org/10.1115/1.3425374

White CS (1992) An Analysis of the Thin-Walled Torsion Specimen. J Eng Mater Technol 114:384–389. https://doi.org/10.1115/1.2904189

Peng X, Qin Y, Balendra R (2001) Finite element investigation into the torsion test in the range of large strains and deformations. J Strain Anal Eng Des 36:401–409. https://doi.org/10.1243/0309324011514566

Ramagiri B, Yerramalli CS (2021) Numerical investigation on the effect of specimen grip** arrangement on dynamic shear characterization using Torsion Split Hopkinson Bar. Eur Phys J Web Conf 250(4):02032. https://doi.org/10.1051/epjconf/202125002032

Funding

This project was funded and supported by National Natural Science Foundation of China (51975 509).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, Y., Duan, Y., Fu, P. et al. On Orthotropic Elastic Constitutive Modeling for Springback Prediction. Exp Mech 64, 3–19 (2024). https://doi.org/10.1007/s11340-023-01005-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-023-01005-1