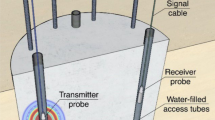

The effect of drilling-induced delamination defects on the buckling behavior of open-hole composite laminates specimens is experimentally studied. PTFE (polytetrafluoroethylene) films are inserted into the ply interface around the hole as artificial delaminations to quantify the drilling-induced one. Artificial delaminations in two shapes (circular and square) and three sizes (10, 15, and 20 mm) are designed. The effect of various drilling-induced delaminations on local buckling, local buckling-induced delamination and general buckling are examined and evaluated using an ultrasonic C-Scan UPK-T48-HS and the digital image measurement system (VIC-3D). Quantitative information, including critical buckling loads, are provided to assess the effect of drilling-induced delamination on the compressive behavior of composite laminates with open holes. The results are expected to give an insight into the assessment of the damage tolerance of the interstage design and establishment of appropriate thresholds for a safety inspection.

Similar content being viewed by others

References

A. Haeger, G. Schoen, F. Lissek, et al., “Non-destructive detection of drilling-induced delamination in CFRP and its effect on mechanical properties,” Procedia Engineer., 149, 130–142 (2016).

C. C. Tsao and H. Hocheng, “Computerized tomography and C-Scan for measuring delamination in the drilling of composite materials using various drills,” Int. J. Mach. Tool. Manu., 45, No. 11, 1282–1287 (2005).

D. Liu, Y. Tang, and W. L. Cong, “A review of mechanical drilling for composite laminates,” Compos. Struct., 94, No. 4, 1265–1279 (2012).

S. O. Ojo, S. O. Ismail, M. Paggi, and H. N. Dhakal, “A new analytical critical thrust force model for delamination analysis of laminated composites during drilling operation,” Compos. Part B-Eng., 124, 207–217 (2017).

A. M. Abrao, P. E. Faria, J. C. C. Rubio, et al., “Drilling of fiber reinforced plastics: A review,” J. Mater. Process. Tech., 186, Nos. 1–3, 1–7 (2007).

X. Qiu, P. Li, C. Li, et al., “Study on chisel edge drilling behavior and step drill structure on delamination in drilling CFRP,” Compos. Struct., 263, 404–413 (2018).

D. Cao, Q. Duan, H. Hu, et al., “Computational investigation of both intra-laminar matrix cracking and inter-laminar delamination of curved composite components with cohesive elements,” Compos. Struct., 192, 300–309 (2018).

N. Z. Karimi, H. Heidary, M. Fotouhi, and G. Minak, “Experimental analysis of GFRP laminates subjected to compression after drilling,” Compos. Struct., 169, 144–152 (2017).

M. Saleem, R. Zitoune, I. El Sawi, and H. Bougherara, “Role of the surface quality on the mechanical behavior of CFRP bolted composite joints,” Int. J. Fatigue, 80, 246–256 (2015).

Z. Y. Pan, Q. F. Duan, Y. C. Zhong, et al., “Stacking sequence effect on the fracture behavior of narrow L-shaped cross-ply laminates: Experimental study,” Strength Mater., 50, No. 1, 203–210 (2018).

R. Zitoune, L. Crouzeix, F. Collombet, et al., “Behaviour of composite plates with drilled and moulded hole under tensile load,” Compos. Struct., 93, No. 9, 2384–2391 (2011).

V. V. Bolotin, “Mechanics of delaminations in laminate composite structures,” Mech. Compos. Mater., 37, Nos. 5–6, 367-380 (2001).

K. F. Nilsson, L. E. Asp, J. E. Alpman, et al., “Delamination buckling and growth for delaminations at different depths in a slender composite panel,” Int. J. Solids Struct., 38, No. 17, 3039–3071 (2001).

A. T. Rhead, R. Butler, and G. W. Hunt, “Compressive strength of composite laminates with delaminationinduced interaction of panel and sublaminate buckling modes,” Compos. Struct., 171, 326–334 (2017).

V. A. Phadnis, F. Makhdum, A. Roy, and V. V. Silberschmidt, “Drilling in carbon/ epoxy composites: Experimental investigations and finite element implementation,” Compos. Part A-Appl. S., 47, 41–51 (2013).

C. C. Tsao and H. Hocheng, “Effect of eccentricity of twist drill and candle stick drill on delamination in drilling composite materials,” Int. J. Mach. Tool. Manu., 45, No. 2, 125–130 (2005).

Acknowledgments

This research work was supported by the Fundamental Research Funds for the Central Universities (WUT: 2018III066GX) and China Postdoctoral Science Foundation (No. 2018M632933).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated from Problemy Prochnosti, No. 4, pp. 141 – 149, July – August, 2019.

Rights and permissions

About this article

Cite this article

Duan, Q.F., Li, S.X., Song, P.H. et al. Effect of Drilling-Induced Delamination on Buckling Behavior of Open Hole Composite Laminate Specimens Under Compressive Loading. Strength Mater 51, 624–632 (2019). https://doi.org/10.1007/s11223-019-00109-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11223-019-00109-1