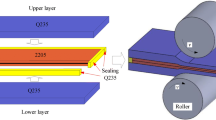

The stainless steel-carbon steel clad plate was investigated using the theoretical analysis of various factors influencing the high-temperature interfacial bonding during its rolling. Phenomenological prediction analysis model of interfacial bonding strength at high temperature which considers the vacuum depth, rolling temperature, and rolling reduction, was established. The specific thermal simulation experiment was designed. The bonding strengths of carbon steel and stainless steel at 1000~1200°C and compression degree of 10~30% were measured by a Gleeble 3500 thermal simulator, as a result, the interfacial bonding ratio was obtained. The results show that the bonding ratio is 0.5–0.65 at the experimental temperature and compression degree. The numerical simulation method was used to analyze the influence of the compression degree of the first pass for a 2000 × 1500 × 100 mm stainless steel clad plate under the interfacial bonding conditions. The simulation results show that the optimum compression degree of the first pass is 15–20% at the rolling temperature of 1200°C.

Similar content being viewed by others

References

L. Li, K. Nagai, and F. X. Yin, “Progress in cold roll bonding of metals,” Sci. Technol. Adv. Mat., 9, No. 2, 023001 (2008), DOI: https://doi.org/10.1088/1468-6996/9/2/023001.

M. Yang, X. Zuo, M. Zhao, and J. Wang, “Research progress of manufacturing technology for stainless steel clad plate hot,” Work. Technol., 20, 027 (2012).

Y. H. Yang, G. Y. Lin, D. D. Chen, et al., “Fabrication of Al–Cu laminated composites by diffusion rolling procedure,” Mater. Sci. Technol., 30, No. 8, 973–976 (2014).

R. Abedi and A. Akbarzadeh, “Bond strength and mechanical properties of three-layered St/AZ31/St composite fabricated by roll bonding,” Mater. Design, 88, 880–888 (2015).

H. Kim, G. T. Kang, and S. I. Hong, “Thermomechanical processing and roll bonding of tri-layered Cu-Ni-Zn/Cu-Cr/Cu-Ni-Zn composite,” Metall. Mater. Trans. A, 47, No. 5, 2267–2276 (2016).

M. M. Hoseini-Athar and B. Tolaminejad, “Interface morphology and mechanical properties of Al-Cu-Al laminated composites fabricated by explosive welding and subsequent rolling process,” Met. Mater. Int., 22, No. 4, 670–680 (2016).

Z. J. Wang, L. Zhai, M. Ma, et al., “Microstructure, texture and mechanical properties of Al/Al laminated composites fabricated by hot-rolling,” Mater. Sci. Eng. A, 644, 194–203 (2015).

M. Ma, P. Huo, W. C. Liu, et al., “Microstructure and mechanical properties of Al/Ti/Al laminated composites prepared by roll bonding,” Mater. Sci. Eng. A, 636, 301–310 (2015).

W. N. Kim and I. H. Sun, “Interactive deformation and enhanced ductility of tri-layered Cu/Al/Cu clad composite,” Mater. Sci. Eng. A, 651, 976–986 (2015).

J. S. Kim, J. Park, K. S. Lee, et al., “Correlation between bonding strength and mechanical properties in Mg/Al two-ply clad sheet,” Met. Mater. Int., 22, No. 5, 771–780 (2016).

X. B. Li, G. Y. Zu, and P. Wang, “High strain rate tensile performance and microstructural evolution of Al/Cu laminated composite under dynamic loading,” Mater. Sci. Eng. A, 612, No. 33, 89–95 (2014).

Y. Zhang, S. Ji, G. Scamans, and Z. Fan, “Interfacial characterisation of overcasting a cast Al-Si-Mg (A356) alloy on a wrought Al-Mg-Si (AA6060) alloy,” J. Mater. Process. Technol., 243, 197–204 (2017).

H. Kim and I. H. Sun, “Deformation and fracture of diffusion-bonded Cu-Ni-Zn/Cu-Cr layered composite,” Mater. Design, 67, 42–49 (2015).

X. Li, G. Zu, and P. Wang, “Effect of Strain rate on tensile performance of Al/Cu/Al laminated composites produced by asymmetrical roll bonding,” Mater. Sci. Eng. A, 575, No. 13, 61–64 (2013).

L. Meng, L. Zhang, Zhou, S. P. Yang, et al., “Effect of annealing temperature on separation strength of Ag/Cu composite plate,” Trans. Mater. Heat Treat., 23, No. 3, 31–34 (in Chinese) (2002).

S. P. Lu, H. M. Yang, J. S. Yu, et al., “Effect of composite rolling deformation on Ag/Cu bondng interface,” Rare Metals, 37, No. 2, 330–334 (in Chinese) (2013).

X. P. Zhang, T. H. Yang, S. Castagne, et al., “Proposal of bond criterion for hot roll bonding and its application,” Mater. Design, 32, No. 4, 2239–2245 (2011).

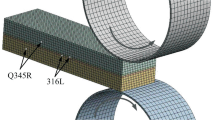

Q. Qin, D. T. Zhang, Y. Zang, and B. Guan, “A simulation study on the multi-pass rolling bond of 316L/Q345R stainless clad plate,” Adv. Mech. Eng., 7, No. 7, 1–13 (2015).

H. Wang, X. Cheng, S. Fu, et al., “Influence of first reduction ratio on the interfacial bonding properties of composite plate of hot rolled stainless steel,” Forg. Stamp. Technol., 41, No. 4, 19–24 (2016).

L. Li, X. J. Zhang, H. Y. Lin, and F. X. Yin, “Formation mechanism of oxide inclusion on the interface of hot-rolled stainless steel clad plates,” J. Iron Steel Res., 25, No. 1, 43–47 (2013).

C. Y. Sun, L. Li, M. W. Fu, and Q. J. Zhou, “Element diffusion model of bimetallic hot deformation in metallurgical bonding process,” Mater. Design, 94, 433–43 (2016).

L. R. Vaidyanath., M. G. Nicholas., and D. R. Milner, “Pressure welding by rolling,” Br. Weld. J., 6, 13–28 (1959).

H. A. Mohamed and J. Washburn, “Mechanism of solid state pressure welding,” Weld. J., 54, 302–310 (1975).

X. P. Zhang, T. H. Yang, S. Castagne, and J. T. Wang, “Microstructure; bonding strength and thickness ratio of Al/Mg/Al alloy laminated composites prepared by hot-rolling,” Mater. Sci. Eng. A, 528, Nos. 4–5, 1954–1960 (2011).

J. M. Parks, “Recrystallization in welding,” Weld. J., 32, No. 5, 209s–221s (1953).

R. Jamaati and M. R. Toroghinejad, “Effect of friction, annealing conditions and hardness on the bond strength of Al/Al strips produced by cold roll bonding process,” Mater. Design, 31, No. 9, 4508–4513 (2010).

P. He, J. C. Feng, and Y. Y. Qian, “A new model of interfacial physical contact in diffusion bonding,” J. Mater. Sci. Technol., 20, No. 1, 109–112 (2004).

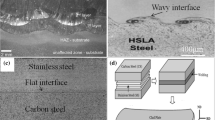

H. M. Ding, X. L. Fan, J. F. Wang, et al., “Interface characterization of hot-rolled stainless steel/carbon steel clad,” Trans. Mater. Heat Treat., 32, No. 11, 18–22 (2011).

H. C. Schmidt, W. Homberg, C. Hoppe, et al., “Cold pressure welding by incremental rolling: Deformation zone analysis,” AIP Conf. Proc., 1766, Issue 1, 100013 (2016), DOI: https://doi.org/10.1063/1.4963507.

J. Song, “Investigation into friction condition in finite element analysis of rolling problem,” Lubr. Eng., 5, 17–21 (1992).

Q. J. Chen, Y. L. Kang, H. P. Hu, et al., “Simulation of rolling process for wide and thin plate of alloy steel by finite element method,” J. Plast. Eng., 12, 163–167 (2005).

Acknowledgments

The authors would like to acknowledge the financial support provided by the National High Technology Research and Development Program of China (No. 2013AA031302), Bei**g Municipal Natural Science Foundation (No. 3154036), and Fundamental Research Funds for the Central Universities of China (No. FRF-TP-16-010A3).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Problemy Prochnosti, No. 1, pp. 91 – 105, January – February, 2018.

Rights and permissions

About this article

Cite this article

Guan, B., Chen, B.Y., Zang, Y. et al. Prediction of a High Temperature Bonding Condition at the Interface for the Hot-Rolled Stainless Steel Clad Plate on Rolling. Strength Mater 50, 79–91 (2018). https://doi.org/10.1007/s11223-018-9945-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11223-018-9945-1