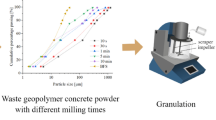

This article presents the development of a method for producing a finely dispersed fraction of ground blast-furnace granulated slag. The resulting material with an alkaline additive can serve as an alternative to analogous finely dispersed mineral binders such as microcement. A comprehensive study was conducted on granulated slags from two metallurgical plants. The physical and chemical characteristics of the materials were determined. Finally, we demonstrated the possibility of producing a fraction of ground granular slag with a particle size of no more than 16 microns using vortex electromagnetic homogenization and subsequent air classification.

Similar content being viewed by others

References

R. M. Aloyan, S. V. Fedosov, L. A. Oparina, and N. I. Yarmolinskaya, The Use of Wastes of Heat and Power Industry of the Far East in the Technology of Building Materials: study guide, Izdatel’stvo Khabar. gos. tekhn. un-ta, Khabarovsk (2000).

P. P. Stupachenko, Building Materials from Industrial Wastes of the Far East [in Russian], Vladivostok, (1988).

L. K. Turner, F. G. Collins, “Carbon dioxide equivalent (CO2-e) emissions: a comparison between geopolymer and OPC cement concrete,” Constr. Build. Mater., 25, 125 – 130 (2013).

R. Kajaste, M. Hurme, “Cement industry greenhouse gas emissions) management options and abatement cost,” J. Clean. Prod., 112, 4041 – 4052 (2016).

P. Humbert, J. Castro-Gomes, and H. Savastano, “Clinker-free CO2 cured steel slag based binder: optimal conditions and potential applications,” Constr. Build. Mater., 210, 413 – 421 (2019).

S.-D. Wang, K. Scrivenera, “Hydration products of alkali activated slag cement,” Cem. Concr. Res., 25, 561 – 571 (1995).

F. Puertas, M. Palacios, and H. Manzano, “A model for the C–A–S–H gel formed in alkali-activated slag cements,” J. Eur. Ceram. Soc., 31, 2043 – 2056 (2011).

X. Yan, L. Jiang, and M. Guo, “Evaluation of sulfate resistance of slag contained concrete under steam curing,” Const. Build. Mat., 195, 231 – 237 (2019).

E. Gruyaert, P. Van den Heede, and M. Maes, “Investigation of the influence of blast-furnace slag on the resistance of concrete against organic acid or sulphate attack by means of accelerated degradation tests,” Cem. Concr. Res., 42, No. 1, 173 – 185 (2012).

H. Zhu, G. Liang, and H. Li, “Insights to the sulfate resistance and microstructures of alkali-activated metakaolin/slag pastes,” Appl. Clay Sci., 202 (2021).

A. Rashad, D. Sadek, “Behavior of alkali-activated slag pastes blended with waste rubber powder under the effect of freeze/thaw cycles and severe sulfate attack,” Const. Build. Mater., 265, Article No. 120716 (2020).

Y. Liu, Z. Zhang, and G. Hou, “Preparation of sustainable and green cement-based composite binders with high-volume steel slag powder and ultrafine blast furnace slag powder,” J. Clean. Prod., Article No. 125133 (2020).

I. Celik, “The effects of particle size distribution and surface area upon cement strength development,” Powder Technol., 188(3), 272 – 276 (2009).

A. I. Panchenko, I. Ya. Kharchenko, “Extra finely dispersed mineral binder Microdur: properties, technology and prospects of use,” Stroit. Mater., No. 10, 76 – 78 (2005).

K. Wang, S. Shah, and A. Mishulovich, “Effects of curing temperature and NaOH addition on hydration and strength development of clinker-free CKD-fly ash binders,” Cem. Concr. Res., 34(2), 299 – 309 (2004).

B. B. Khaidarov, D. S. Suvorov, D. V. Lysov, et al., “Research of mineral hydraulic binders based on the slag-cement system obtained with the use of vortex electromagnetic homogenization,” Nov. Ogneup., No. 2, 45 – 50 (2021).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Novye Ogneupory, No. 6, pp. 56 – 63, June, 2021.

Rights and permissions

About this article

Cite this article

Khaidarov, B.B., Suvorov, D.S., Lysov, D.V. et al. Production and Investigation of a Finely Dispersed Fraction of Blast-Furnace Granulated Slag for Use as Components of Clinker-Free Binders. Refract Ind Ceram 62, 347–354 (2021). https://doi.org/10.1007/s11148-021-00606-4

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11148-021-00606-4