Abstract

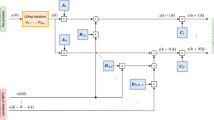

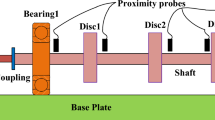

Considering the flexibility of the shaft and joints between the motor and the load, the servo drive system can be regarded as a dual-inertia system. Firstly, flexible components in the servo system such as coupling are equivalent to flexible joints, and the servo drive system with transmission efficiency is established. Next, a gear model including the variable friction coefficient, stiffness, backlash, and transmission error is built, and the transmission efficiency is calculated by the gear vibration displacement and speed. Then, the PI controller parameters are obtained by three pole assignment methods, and the adaptive controller with adjustable PID parameters is designed based on the BP neural network. Finally, the speed change at the load side with three pole assignment methods and BP-PID method is analyzed. The effects of control parameters and methods on the dynamic characteristics of gear are studied.

Similar content being viewed by others

Data availability

The data used to support the findings of this study are included within the article. The processed data are available from the corresponding author upon request.

References

Zhang, G., Furusho, J.: Speed control of two-inertia system by pi/pid control. IEEE Trans. Ind. Electron. 47(3), 603–609 (2000). https://doi.org/10.1109/PEDS.1999.794627

Wang, L., Wang, D., Wu, J.: Dynamic performance analysis of parallel manipulators based on two-inertia-system. Mech. Mach. Theory 137, 237–253 (2019). https://doi.org/10.1016/j.mechmachtheory.2019.03.023

Y. Ding, X. **ao, parameter tuning methods based on pole placement for pi controllers of flexible loads driven by PMSM, Proceedings of the CSEE. 37(4) (2017) 1225-1238.DOI: https://doi.org/10.13334/j.0258-8013.pcsee.160212https://doi.org/10.13334/j.0258-8013.pcsee.160212

Xu, J., Li, X., Yang, Z., Su, J., Chen, R., Shang, D.: Transmission friction measurement and suppression of dual-inertia system based on RBF neural network and nonlinear disturbance observer. Measurement 1(202), 111793 (2022). https://doi.org/10.1016/j.measurement.2022.111793

Li, X., Shang, D., Chen, R., Wen, B.: Control strategy of flexible load servo drive system based on manipulator position and position transformation. J. Mech. Eng. 56(21), 69–82 (2020). https://doi.org/10.3901/JME.2020.00.000

Lu, L., Wu, Q., Chen, X., Shao, Z., Chen, B., Wu, H.: Development of a sEMG-based torque estimation control strategy for a soft elbow exoskeleton. Robot. Auton. Syst. (2018). https://doi.org/10.1016/j.robot.2018.10.017

Xu, D., Wu, Q., Zhu, Y.: Development of a sEMG-based joint torque estimation strategy using hill-type muscle model and neural network. J. Med. Biol. Eng. 41(1), 34–44 (2020). https://doi.org/10.1007/s40846-020-00539-2

Shao, Z., Wu, Q., Chen, B., Wu, H., Zhang, Y.: Modeling and inverse control of a compliant single-tendon-sheath artificial tendon actuator with bending angle compensation. Mechatronics 63, 102262 (2019). https://doi.org/10.1016/j.mechatronics.2019.102262

Wu, Q., Wang, X., Chen, B., Wu, H.: Modeling, online identification, and compensation control of single tendon sheath system with time-varying configuration. Mech. Syst. Signal Proc. 130(Sep1), 56–73 (2019). https://doi.org/10.1016/j.ymssp.2019.05.007

Liu, H., Yan, P., Gao, P.: Effects of temperature on the time-varying mesh stiffness, vibration response, and support force of a multi-stage planetary gear. J. Vib. Acoust. 142(5), 051110 (2020). https://doi.org/10.1115/1.4047246

Ba, W., Qin, D., Wang, Y., Lim, T.: Dynamic characteristic of electromechanical coupling effects in motor-gear system. J. Sound Vibr. 423, 50–64 (2018). https://doi.org/10.1016/j.jsv.2018.02.033

Ba, W., Qin, D., Wang, Y., Lim, T.: Dynamic characteristics of motor-gear system under load saltations and voltage transients. Mech. Syst. Signal Proc. 100, 1–16 (2018). https://doi.org/10.1016/j.ymssp.2017.07.039

Hou, S., Wei, J., Zhang, A., Lim, T.C., Zhang, C.: Study of dynamic model of helical/herringbone planetary gear system with friction excitation”. J. Comput. Nonlinear Dyn. 10(1115/1), 4041774 (2018)

Li, X., Xu, J., Yang, Z., Chen, R., Yang, H.: The influence of tooth surface wear on dynamic characteristics of gear-bearing system based on fractal theory. J. Comput. Nonlinear Dyn. (2020). https://doi.org/10.1115/1.4046053

Diez-Ibarbia, A., del Rincon, A.F., Iglesias, M., De-Juan, A., Garcia, P., Viadero, F.: Efficiency analysis of spur gears with a shifting profile. Meccanica 51, 707–723 (2016). https://doi.org/10.1007/s11012-015-0209-x

Diez-Ibarbia, A., Fernandez-del-Rincon, A., De-Juan, A., Iglesias, M., Garcia, P., Viadero, F.: Frictional power losses on spur gears with tip reliefs. The friction coefficient role. Mech. Mach. Theory 121, 15–27 (2018). https://doi.org/10.1016/j.mechmachtheory.2017.10.003

Yin, M., Wu, H., Xu, Z., Han, W., Zhao, Z.: Compliant control of single tendon-sheath actuators applied to a robotic manipulator. IEEE Access. 99(8), 37361–37371 (2020). https://doi.org/10.1109/ACCESS.2020.2973173

Yin, M., Xu, Z., Zhao, Z., Wu, H.: Mechanism and position tracking control of a robotic manipulator actuated by the tendon-sheath. J. Intell. Robot. Syst. 100, 849–862 (2020). https://doi.org/10.1007/s10846-020-01245-6

Yang, T., Yan, S., Ma, W., Han, Z.: Joint dynamic analysis of space manipulator with planetary gear train transmission. Robotica 34(5), 1042–1058 (2016). https://doi.org/10.1017/S0263574714002045

Chen, Y., Yang, M., Long, J., Hu, K., Xu, D., Blaabjerg, F.: Analysis of oscillation frequency deviation in elastic coupling digital drive system and robust notch filter strategy. IEEE Trans. Industr. Electron. 66(1), 90–101 (2018). https://doi.org/10.1109/TIE.2018.2825300

Kahraman, A., Singh, R.: Non-linear dynamics of a geared rotor-bearing system with multiple clearances. J. Sound Vibr. 144(3), 469–506 (1991). https://doi.org/10.1016/0022-460X(91)90564-Z

**u-feng, T.A., Guo-wei, Z.H., Li-yang, X.I., Xue-hong, H.E.: Summary and outlook on gear system’s kinetic study. J. Mech. Electr. Eng. (2014). https://doi.org/10.3969/j.issn.1001-4551.2014.05.004

Kahraman, A., Singh, R.: Interactions between time-varying mesh stiffness and clearance non-linearities in a geared system. J. Sound Vibr. 146(1), 135–156 (1991). https://doi.org/10.1016/0022-460X(91)90527-Q

Song, H., Cho, S., Singh, R.: Prediction of dynamic friction forces in spur gears using alternate sliding friction formulations. J. Sound Vibr. 309(3–5), 843–851 (2008). https://doi.org/10.1016/j.jsv.2007.06.077

Lu, H., Xu, Y., Yang, W., Chen, Z.: Fuzzy PID controller design for a permanent magnet linear synchronous motor feeding system. Trans. China Electrotech. Soc. 22(4), 59–63 (2007). https://doi.org/10.1631/jzus.2007.A1596

Ma, H., Yang, J., Song, R., Zhang, S., Wen, B.: Effects of tip relief on vibration responses of a geared rotor system. Proceed. Inst. Mech. Eng., Part C: J. Mech. Eng. Sci. 228(7), 1132–1154 (2014). https://doi.org/10.1177/0954406213500615

Funding

The project is supported by the National Natural Science Foundation of China (No. 52275090), the Fundamental Research Funds for the Central Universities (N2103025), and the National Key Research and Development Program of China (2020YFB2007802).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Xu, J., Li, X., Su, J. et al. Dynamic characteristics analysis of gear system with time-varying torque of motor and load based on motor control strategy. Nonlinear Dyn 112, 2611–2628 (2024). https://doi.org/10.1007/s11071-023-09193-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11071-023-09193-0