Abstract

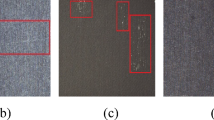

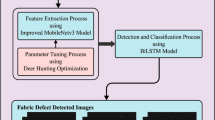

Fabric Defect (FD) detection has played an important role in the process of fabric production. FDs lead to a reduction in cloth prices, causing a significant loss of 45% to 65% for the cloth manufacturer. The detection of FDs becomes a challenging task in the fabric industry due to its complicated shapes and a considerable amount of FDs. Thus, a new detection technique, which has great detection speed and accuracy, is desired to replace manual work. With the emergence of Convolution Neural Networks (CNN) and the development of machine vision and Deep Learning (DL), various detection techniques, combining the benefits of DL and machine vision, have emerged, which replace manual and image processing approaches. The study presents an Automated Fabric Defect Detection using a Hybrid Particle Cat Swarm Optimizer with a Deep Learning (AFDD-HPCSODL) algorithm. AFDD-HPCSODL method aims to detect and categorize the existence of defects in fabric production. The objective is to automate and improve the performance of fabric defect detection, addressing the complexity of different defect patterns and characteristics in textile images. In the presented AFDD-HPCSODL technique, two stages of data pre-processing take place namely contrast enhancement and bilateral filtering (BF)-based noise elimination. Besides, a fusion of feature extraction processes is carried out using Inception V3 and EfficientNetB3. Moreover, the Attention Convolutional Long Short-Term Memory (ACLSTM) network is exploited for the detection and classification of FDs. Furthermore, the HPCSO technique carries out the hyperparameter selection of the ACLSTM model. Finally, the Root Mean Square Propagation (RMSProp) optimizer with the NestNet model is utilized for the defect segmentation process. The stimulation validation of the AFDD-HPCSODL method is studied on the two FD datasets. Widespread comparative results emphasized the improved performance of the AFDD-HPCSODL technique on FD classification with maximum accuracy of 97.92% and 98.89% on the Kaggle FD dataset and the ZJU-Leaper dataset, correspondingly.

Similar content being viewed by others

Data availability

Not applicable.

References

Dlamini S, Kao CY, Su SL, Jeffrey Kuo CF (2022) Development of a real-time machine vision system for functional textile fabric defect detection using a deep YOLOv4 model. Text Res J 92(5–6):675–690

Huang Y, **g J, Wang Z (2021) Fabric defect segmentation method based on deep learning. IEEE Trans Instrum Meas 70:1–15

Ouyang W, Xu B, Hou J, Yuan X (2019) Fabric defect detection using activation layer embedded convolutional neural network. IEEE Access 7:70130–70140

**e H, Xu W (2023) Effective fabric defect detection using contrastive learning and layered fusion network. In: Fourteenth International Conference on Graphics and Image Processing (ICGIP 2022). Nan**g, China. SPIE 12705:199–208

Han YJ, Yu HJ (2020) Fabric defect detection system using stacked convolutional denoising auto-encoders trained with synthetic defect data. Appl Sci 10(7):2511

Zheng L, Wang X, Wang Q, Wang S, Liu X (2021) A fabric defect detection method based on improved yolov5. In: 2021 7th International Conference on Computer and Communications (ICCC), pp 620-624. IEEE.

**e Q, Li D, Xu J, Yu Z, Wang J (2019) Automatic detection and classification of sewer defects via hierarchical deep learning. IEEE Trans Autom Sci Eng 16(4):1836–1847

Fang B, Long X, Sun F, Liu H, Zhang S, Fang C (2022) Tactile-based fabric defect detection using convolutional neural network with attention mechanism. IEEE Trans Instrum Meas 71:1–9

An M, Wang S, Zheng L, Liu X (2020) Fabric defect detection using deep learning: An improved faster R-approach. In: 2020 International Conference on Computer Vision, Image and Deep Learning (CVIDL). Chongqing, China, pp 319–324. https://doi.org/10.1109/CVIDL51233.2020.00-78

Zhou Q, Sun H, Chen P, Chen G, Wang S, Wang H (2023) Research on the defect detection algorithm of warp-knitted fabrics based on improved YOLOv5. Fibers Polym 24:2903–2919. https://doi.org/10.1007/s12221-023-00253-1

**g J, Wang Z, Rätsch M, Zhang H (2022) Mobile-Unet: An efficient convolutional neural network for fabric defect detection. Text Res J 92(1–2):30–42

Peng P, Wang Y, Hao C, Zhu Z, Liu T, Zhou W (2020) Automatic fabric defect detection method using PRAN-net. Appl Sci 10(23):8434

Jun X, Wang J, Zhou J, Meng S, Pan R, Gao W (2021) Fabric defect detection is based on a deep convolutional neural network using a two-stage strategy. Text Res J 91(1–2):130–142

Liu Q, Wang C, Li Y, Gao M, Li J (2022) A fabric defect detection method based on deep learning. IEEE access 10:4284–4296

** R, Niu Q (2021) Automatic fabric defect detection based on an improved YOLOv5. Math Probl Eng 2021:1–13

Zhan Z, Zhou J, Xu B (2022) Fabric defect classification using prototypical network of few-shot learning algorithm. Comput Ind 138:103628

Almeida T, Moutinho F, Matos-Carvalho JP (2021) Fabric defect detection with deep learning and false negative reduction. IEEE Access 9:81936–81945

Chen M, Yu L, Zhi C, Sun R, Zhu S, Gao Z, Ke Z, Zhu M, Zhang Y (2022) Improved faster R-CNN for fabric defect detection based on Gabor filter with genetic algorithm optimization. Comput Ind 134:103551

Rao EG, Kumar YP (2017) De-noising and contrast enhancement using bilateral filter and adaptive histogram equalization. Comput Sci 41(6):90–96

Ramaneswaran S, Srinivasan K, Vincent PDR, Chang CY (2021) Hybrid inception v3 XGBoost model for acute lymphoblastic leukemia classification. Comput Math Methods Med 2021:1–10

Shah SA, Lakho GM, Keerio HA, Sattar MN, Hussain G, Mehdi M, Vistro RB, Mahmoud EA, Elansary HO (2023) Application of drone surveillance for advance agriculture monitoring by android application using convolution neural network. Agronomy 13(7):1764

Liu F, Jiang X, Wu Z (2023) Attention mechanism-combined LSTM for grain yield prediction in China using multi-source satellite imagery. Sustainability 15(12):9210

Zomorodi-moghadam M, Abdar M, Davarzani Z, Zhou X, Pławiak P, Acharya UR (2021) Hybrid particle swarm optimization for rule discovery in the diagnosis of coronary artery disease. Expert Systems 38(1):e12485

Tsai PW, Pan JS, Chen SM, Liao BY, Hao SP (2008) Parallel cat swarm optimization. In: 2008 international conference on machine learning and cybernetics 2008 International Conference on Machine Learning and Cybernetics. Kunming, pp 3328–3333. https://doi.org/10.1109/ICMLC.2008.4620980

Yu X, Fan J, Chen J, Zhang P, Zhou Y, Han L (2021) NestNet: A multiscale convolutional neural network for remote sensing image change detection. Int J Remote Sens 42(13):4898–4921

Babu DV, Karthikeyan C, Kumar A (2020) Performance analysis of cost and accuracy for whale swarm and RMSprop optimizer. IOP Conf Ser: Mater Sci Eng 993(1):012080 (IOP Publishing)

https://www.kaggle.com/datasets/rmshashi/fabric-defect-dataset. Accessed 14 June 2023

http://www.qaas.zju.edu.cn/zju-leaper/. Accessed 14 June 2023

Jun X, Ruru Pan, Weidong G (2022) Online detection of fabric defects based on improved centernet with deformable convolution. Sensors 22:4718. https://doi.org/10.3390/s22134718

Amelio A, Bonifazi G, Corradini E, Di Saverio S, Marchetti M, Ursino D, Virgili L (2022) Defining a deep neural network ensemble for identifying fabric colors. Appl Soft Comput 130:109687

Funding

The authors did not receive support from any organization for the submitted work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Ethical consideration

Not applicable.

Human participants and/or animals

Not applicable.

Conflict of interest

The authors have expressed no conflict of interest.

Additional information

Publisher's Note

Data sharing is not applicable to this article as no datasets were generated or analyzed during the current study.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sajitha, N., Priya, S.P. Automated fabric defect detection using hybrid particle cat swarm optimizer with deep learning model. Multimed Tools Appl (2024). https://doi.org/10.1007/s11042-024-18425-3

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11042-024-18425-3