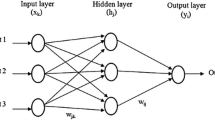

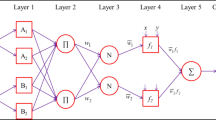

The effects of cattail/poplar straw weight ratio, sandwich panel thickness, and the number of kraft paper layers at the core of sandwich panels on the modulus of rupture (MOR) of the panels were predicted using an artificial neural network (ANN) and an adaptive neuro-fuzzy inference system (ANFIS). The prediction accuracy of the MOR based on experimental data, in terms of the mean absolute percentage error, was smaller than 1.4 and 1.1%, with coefficients of determination 0.94 and 0.995 for the ANN and ANFIS models, respectively. These models can easily predict the bending strength of lignocellulosic-based sandwich panels with a high precision in the manufacturing process.

Similar content being viewed by others

References

S. Hou, S. Zhao, L. Ren, X. Han, and Q. Li, “Crashworthiness optimization of corrugated sandwich panels,” Mater. Des., 51, 1071-1084 (2013).

Z. N.Azwa, B. F.Yousif, A. C. Manalo, and W. Karunasena, “A review on the degradability of polymeric composites based on natural fibres,” Mater. Des., 47, 424-42 (2013).

S. Tiryaki, S. Ozşahin, and I. Yıldırım, “Comparison of artificial neural network and multiple linear regression models to predict optimum bonding strength of heat treated woods,” Int. J. Adhes. Adhes., 55, 29-36 (2014).

S. Tiryaki and A. Aydın, “An artificial neural network model for predicting compression strength of heat treated woods and comparison with a multiple linear regression model,” Constr. Build. Mater., 62, 102-108 (2014).

F. G. Fernandez, P. Palacios, L. G. Esteban, A. G. Iruela, B. G. Rodrigo, and E. Menasalvas, “Prediction of MOR and MOE of structural plywood board using an artificial neural network and comparison with a multivariate regression model,” Compos. Part B., 43, No. 8, 3528-3533.

R. Kurt, “Determination of the most appropriate statistical method for estimating the production values of medium density fiberboard,” BioResources., 14, No. 3, 6186-6202 (2019).

K. Watanabe, H. Korai, H. Matsushita H, and T. Hayashi,” Predicting internal bond strength of particleboard under outdoor exposure based on climate data: comparison of multiple linear regression and artificial neural network,” J. Wood Sci., 61, 151-158 (2015).

S. Tiryaki, U. Aras, H. Kalaycioglu, E. Erişir, and A. Aydin, “Predictive models for modulus of rupture and modulus of elasticity of particleboard manufactured in different pressing conditions,” High Temp. Mater. Process., 36, No. 6, 1-12 (2016).

S. Bardak, T. Bardak, H. Peker, E. Sözen, and Y. Çabuk, “Predicting effects of selected impregnation processes on the observed bending strength of wood, with use of data mining models”. Bioresources, 16, No. 3, 4891-4904 (2021).

S. Bardak, “Predicting the impacts of various factors on failure load of screw joints for particleboard using artificial neural networks”. BioResources, 13, No. 2, 3868-3879 (2018).

S. Bardak, S. Tiryaki, T. Bardak, and A. Aydin, “Predictive performance of artificial neural network and multiple linear regression models in predicting adhesive bonding strength of wood”. Strength Mater., 48, No.6, 811-824 (2016).

M. Hosoz, H. M. Ertunc, and H. Bulgurcu, “An adaptive neuro-fuzzyinference system model for predicting the performance of a refrigeration system with a cooling tower,” Expert Syst.Appl., 38, No. 11, 14148-55(2011).

J. S. R. Jang. ANFIS: adaptive-network-based fuzzy inference system. Systems, man and cybernetics. IEEE Transaction. 23, 665-85 (1999).

C.D. Lewis. International and business forecasting methods. London:Butterworths; 1982.

A. Canakci, S. Ozsahin, and T. Varol T, “Modeling the influence of a process control agent on the properties of metal matrix composite powders using artificial neural networks,” Powder Technol., 228, 26-35 (2012).

A. A. Tofigh, M. R. Rahimipour, M. O. Shabani, and P. Davami, “Application of the combined neuro-computing, fuzzy logic and swarm intelligence for optimization of compocast nanocomposites,” J. Compos. Mater., 49, 1653-1663 (2015).

M. Shamsipour, Z. Pahlevani, M. O. Shabani, and A. Mazahery,“Optimization of the EMS process parameters in compocasting of high-wear-resistant Al-nano-TiC composites,” Appl. Phys. A., 122, 1 (2016).

M. Ostad Shabani, M. Shamsipour, A. Mazahery, and Z. Pahlevani, “Performance of ANFIS coupled with PSO in manufacturing superior wear resistant aluminum matrix nano composites,” Trans. Indian Inst. Met., 71, 2095-2103 (2018).

S. Zielinska, and E. Kepczynska, “Neural modeling of plant tissue cultures: a review,” BioTechnologia, 94, No. 3, 253-268 (2013).

J. Gago, L. Martinez-Nunez, and M. Landin, “Artificial neural networks as an alternative to the traditional statistical methodology in plant research,” J. Plant Physiol., 167, 23-27 (2010).

A. Ruangmee and C. Sangwichien,“ Statistical optimization for alkali pretreatment conditions of narrow-leaf cattail by response surface methodology,” Songklanakarin J. Sci. Technol., 35, No. 4, 443-450 (2013).

N. S. V. Gupta, Akash, K. V. S. Rao, and D. S. Arunkumar, “Fabrication and evaluation of mechanical properties of alkaline treated sisal/hemp fiber reinforced hybrid composite,” IOP Conf. Series on Mater. Sci. Eng., 149, 012093 (2016).

L. Cai, D. Zhang, S. Zhou S, and W. Xu, “Investigation on mechanical properties and equivalent model of aluminum honeycomb sandwich panels,” J. Mater. Eng. Perform., 27, 6585-6596 (2018).

S. Mudassir, D. V. R. Shankar, and M. M. Hussain,“ Flexural behavior of sandwich composite panels under 4-point loading,” Int. J. Mater. Sci., 11, 47-55 (2016).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Nazerian, M., Deghatkar, B.S. & Vatankhah, E. A Comparative Study of the Estimated Bending Strength of Sandwich Panels by an Artificial Neural Network and an Adaptive Neuro-Fuzzy Inference System. Mech Compos Mater 59, 595–608 (2023). https://doi.org/10.1007/s11029-023-10118-6

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11029-023-10118-6