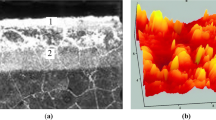

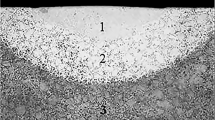

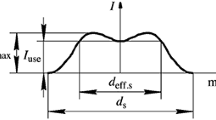

Processes of structure transformation in irradiated steel surface layers, occurring in tribological systems under external thermal deformation action, are considered. It is established that by varying laser radiation regime parameters it is possible to use the structural adaptability phenomenon of irradiated zones in steels intentionally, and to obtain structures within them that have a different degree of adaptation to external loading conditions during operation. This has a positive effect on heat and wear resistance of irradiated products for various functional purposes. It is shown that irradiation with a radiation power density of 80–120 MW/m2 (without melting) leads to strain ageing of laser-hardened martensite. This contributes to creation upon working surfaces of products whose structural state is almost indifferent to thermal deformation loading and is resistant to softening for a long time. With an irradiation power density of 120–170 MW/m2 (with melting), surface structures are formed that adapt to external effects. Laser-hardened austenite transforms into strain-induced martensite under thermal loading action. At the same time, martensite strain ageing occurs within laser irradiation zones. Fine carbides, 2–10 nm in size, precipitate during this time upon crystal structure defects with formation of a precipitate texture. As a result material heat resistance after laser irradiation increases by 50–100°C, and wear resistance by a factor of 2–4. Based upon the experimental results, maps of regression modeling of the laser surface hardening production process are constructed. This permits selection of regimes for both laser processing and operating conditions, and the subsequent product tempering temperature for various functional purposes.

Similar content being viewed by others

References

A. G. Grigor’yants, I. N. Shiganov, and A. I. Misyurov, Laser Treatment Production Processes [in Russian], Izd. MGTU, Moscow (2006).

Yu. D. Klebanov and S. N. Grigor’ev, Physical Bases of Using Concentrated Energy Flows in Material Treatment Technology [in Russian], Izd. MGTU Stankin, Moscow (2005).

V. P. Biryukov, “Effect of laser beam power energy distribution on increase in friction surface wear resistance,” Vvestn. Mashin., No. 3, 33–36 (2008).

D. M. Gureev and S. V. Yamshchikov, Bases of Laser Physics and Material Laser Treatment [in Russian], Izd. SGU, Samara (2001).

Zhang Peng, Jiaheng Yin, and Zhengjiang Hu, “Numerical and experimental investigation on pulsed nanosecond laser ablation processing of aluminum alloy,” Materials Research and Technology, 19, 4708–4720 (2022).

Dongyun Sun, Jun Zhao, and Zhinan Yang, “In-situ observation of phase transformation during heat treatment process of high-carbon bainitic bearing steel,” Materials Research and Technology, 19, 3713–3723 (2022).

L. M. Rybakova and L. I. Kuksenova, Materials Science tasks in the Problem of Metallic Material Wear Resistance [in Russian], Mashinostroenie, Moscow (1991).

Chun-Sheng OuYang, **u-Bo Liu, and De-Qiang Chen, “Preparation and high temperature tribological properties of laser in-situ synthesized self-lubricating composite coating on 304 stainless steel,” Materials Research and Technology, 9, No. 4, 7034–7046 (2020).

Bingxu Wang, Feng Qiu, and Rui Wang, “Microstructure, wear behavior and surface hardening of austempered ductile iron,” Materials Research and Technology, 9, No. 5, 9838–9855 (2020).

Qunli Zhang, Lijuan Wu, and Jianhua Yao, “Correlation between microstructural characteristics and cavitation resistance of Stellite-6 coatings on 17-4 PH stainless steel prepared with supersonic laser deposition and laser cladding,” J. Alloys and Compounds, 860, Art. 158417 (2021).

A. B. Lysenko, “Effect of production factors on composition, structure and properties of a laser chemical-heat treatment zone,” Fiz. Khim. Obrab. Materialov, No. 2, 25–30 (2001).

T. V. Tarasova, “Prospects of using laser radiation for increasing corrosion-resistant steel wear resistance,” MiTOM, No. 6 (660), 54–57 (2010).

A. V. Brover, “Steel combined strengthening with concentrated energy flows,” STIN, No. 3, 34–37 (2007).

Rui Qin, Zhifen Zhang, and Weifeng He, “On-line evaluation and monitoring technology for material surface integrity in laser shock peening – A rev.,” Materials Processing Technology, 313, Art. 1178 (2022).

Hongyu Chen, Dongdong Gu, and Konrad Kosiba, “Laser additive manufactured high-performance Fe-based composites with unique strengthening structure,” Materials Science & Technology, 89, 242–252 (2020).

Renyu Liang, Chun** Huang, and Liming Ke, “Microstructure and mechanical properties of 34CrNiMo6 steel repaired by laser remelting,” Materials Research and Technology, 9, No. 6, 13870–13878 (2020).

K. Wang, D. Du, B. Chang, J. Ju, S. Sun, and H. Fu, “Microstructure and property of laser clad Fe-based composite layer containing Nb and B4C powders,” J. Alloys and Compounds, 802, 373–384 (2019).

G. I. Brover, and E. E. Shcherbakova, “Features of steel structure formation within zones of high-speed laser quenching from a liquid condition,” Metallurg, No. 5, 61–66 (2022).

P. K. Galenko, E. V. Kharanzhevskii, and D. A. Danilov, “High-speed crystallization of structural steel during surface laser treatment,” ZhTF, 72, No. 5, 48–55 (2002).

G. I. Brover, and E. E. Shcherbakova, “Features of structure formation within steel surface layers during laser alloying from coatings of different composition,” Metallurg, No. 6, 55–61 (2022).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, Vol. 67, No. 4, pp. 86–92, April, 2023.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Brover, G.I., Shcherbakova, E.E. Transformation of the Structure and Properties of Laser-Irradiated Steels Under External Thermal Deformation Action. Metallurgist 67, 508–516 (2023). https://doi.org/10.1007/s11015-023-01540-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-023-01540-1