Abstract

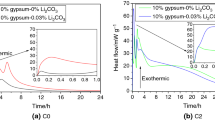

Low hydration and carbonation degree of reactive magnesium oxide cement (RMC) have always hindered the development of its properties. Motivated by the influence of amino acids on biomineralization, this work aimed to investigate the impacts of glutamic acid (Glu), serine (Ser), and arginine (Arg) on the hydration and carbonation of RMC under ambient-curing and accelerated CO2-curing. The exothermic hydration, mechanical strength, phase composition and thermal stability were studied. Results suggested that Glu significantly improved the compressive strength (0.1 M Glu increased strength by 58% at 14 days of accelerated CO2 curing) and hydration degree (71% vs. 57%). The addition of amino acids varies the pH value of the system, and different effects of hydration and carbonation were observed among different amino acid-added samples. This effect can be attributed to the state of the amino acids in the solution at that pH. The negatively charged glutamic acid in the RMC system binds to Mg2+, leads to greater MgO dissolution, enhanced hydration and carbonation, and improved mechanical strength.

Similar content being viewed by others

References

Farooq S, Ozturk I, Majeed MT, Akram R. Globalization and CO2 emissions in the presence of EKC: A global panel data analysis. Gondwana Res. 2022;106:367–78. https://doi.org/10.1016/j.gr.2022.02.002.

Andrew RM. Global CO2 emissions from cement production, 1928–2018. Earth Syst Sci Data. 2019;11(4):1675–710. https://doi.org/10.5194/essd-11-1675-2019.

Gao T, Shen L, Liu L, Chen F, Gao L. Evolution and projection of CO2 emissions for China’s cement industry from 1980 to 2020. Renew Sust Energ Rev. 2017;74:522–37. https://doi.org/10.1016/j.rser.2017.02.006.

Scott A, Shah V, Oze C, Shanks B, Cheeseman C.Use of olivine for the production of MgO-SiO2 binders. Front. Built. Environ. 2021;640243. https://doi.org/10.3389/FBUIL.2021.640243.

Suhr M, Klein G, Kourti I, Gonzalo MR, Santonja GG, Roudier S, Sancho LD. Best Available Techniques (BAT) Reference Document for the Production of Pulp. Paper and Board, 2013.

Shand MA. The Chemistry and Technology of Magnesia. J. Phys. A-Math. Thero. 2006.

Ma A, Effect of calcination temperature on microstructure and properties of magnesium oxide. Chemistry and bonding. 2020;42(3). https://doi:https://doi.org/10.3969/j.issn.1001-0017.2020.03.012.

Ruan S, Unluer C. Comparative life cycle assessment of reactive MgO and Portland cement production. J Clean Prod. 2016;137:258–73. https://doi.org/10.1016/j.jclepro.2016.07.071.

Bhatti AS, Dollimore D, Dyer A. Magnesia from Seawater: A Review. Clay. Miner. 1984;19:865–875. https://https://doi.org/10.1180/claymin.1984.019.5.14.

Xu H, Liu W, Yang X, Shi X, Chen S, Yu L. Preparation of high purity light magnesium oxide from sulphate subtype brines. J. Cent. South Univ. 2011;42(8).

Tan Y, Yu H, Sun S, Wu C, Ding H. Properties and microstructure of basic magnesium sulfate cement: Influence of silica fume. Constr Build Mater. 2021;266: 121076. https://doi.org/10.1016/j.conbuildmat.2020.121076.

Zhang G, Wang Q, Li Y, Zhang M. Microstructure and micromechanical properties of magnesium phosphate cement. Cem Concr Res. 2023;172: 107227. https://doi.org/10.1016/j.cemconres.2023.107227.

Aiken TA, Kwasny J, Russell M, McPolin D, Bagnall L. Effect of partial MgO replacement on the properties of magnesium oxychloride cement. Cem Concr Compos. 2022;134: 104791. https://doi.org/10.1016/j.cemconcomp.2022.104791.

Ruan S, Liang S, Kastiukas G, Zhu W, Zhou X. Solidifcation of waste excavation clay using reactive magnesia, quicklime, sodium carbonate and early-age oven curing. 2020;258: 120333. https://doi.org/10.1016/J.CONBUILDMAT.2020.120333.

Davies PJ, Rutt K, Cressey G. The transformation of nesquehonite into hydromagnesite. Chem Geol. 1973;12:289–300. https://doi.org/10.1016/0009-2541(73)90006-5.

Ballirano P, Vito CD, Mignardi S, Ferrini V. Phase transitions in the MgCO2H2O system and the thermal decomposition of dy**ite, Mg5(CO3)4(OH)2·5H2O: Implications for geosequestration of carbon dioxide. Chem Geol. 2013;340:59–67. https://doi.org/10.1016/j.chemgeo.2012.12.005.

Jauffret G, Morrison J, Glasser FP. On the thermal decomposition of nesquehonite. J Therm Anal Calorim. 2015;122:601–9. https://doi.org/10.1016/j.chemgeo.2012.12.005.

Harrison AL, Mavromatis V, Oelkers EH, Bénézeth P. Solubility of the hydrated Mg-carbonates nesquehonite and dy**ite from 5 to 35 °C: Implications for CO2 storage and the relative stability of Mg-carbonates. Chem. Geol. 2019;504:123–135. https://doi.org/10.1016/j.chemgeo.2018.11.003.

Dung NT, Lesimple A, Hay R, Celik K, Unluer C. Formation of carbonate phases and their effect on the performance of reactive MgO cement formulations. Cem Concr Res. 2019;125: 105894. https://doi.org/10.1016/j.cemconres.2019.105894.

Hay R, Otchere C, Kashwani G, Celik K. Recycling carbonated reactive magnesium cement (RMC) as a building material. J Clean Prod. 2021;320: 128838. https://doi.org/10.1016/j.jclepro.2021.128838.

Unluer C, Al-Tabbaa A. Enhancing the carbonation of MgO cement porous blocks through improved curing conditions. Cem Concr Res. 2014;59:55–65. https://doi.org/10.1016/j.cemconres.2014.02.005.

Hay R, Celik K. Hydration, carbonation, strength development and corrosion resistance of reactive MgO cement-based composites. Cem Concr Res. 2020;128: 105941. https://doi.org/10.1016/j.cemconres.2019.105941.

Dung NT, Hay R, Lesimple A, Celik K, Unluer C. Influence of CO2 concentration on the performance of MgO cement mixes. Cem Concr Res. 2021;115: 103826. https://doi.org/10.1016/j.cemconcomp.2020.103826.

Vandeperre LJ, Al-Tabbaa A. Accelerated carbonation of reactive MgO cements. Adv Cem Res. 2007;19:67–79. https://doi.org/10.1680/adcr.2007.19.2.67.

Wang L, Chen L, Provis JL, Tsang DCW., Poon CS. Accelerated carbonation of reactive MgO and Portland cement blends under flowing CO2 Gas Cem Concr Compos 2020;106:103489. https://doi.org/10.1016/j.cemconcomp.2019.103489.

Tang X, Guo L, Chen C, Liu Q, Li T, Zhu Y. The analysis of magnesium oxide hydration in three-phase reaction system. J Solid State Chem. 2014;213:32–7. https://doi.org/10.1016/j.jssc.2014.01.036.

Dheilly RM, Sebaibi Y, Tudo J, Queneudec M. Importance de la présence de magnésie dans le stockage de la chaux: carbonatation de l’oxyde et de l’hydroxyde de magnesium. Can J Chem. 1998;76:1188–96. https://doi.org/10.1139/v98-126.

Dung NT, Unluer C. Influence of accelerated hydration and carbonation on the performance of reactive magnesium oxide concrete. Adv Cem Res. 2020;32:78–90. https://doi.org/10.1680/jadcr.17.00186.

Dung NT, Unluer C. Carbonated MgO concrete with improved performance: The influence of temperature and hydration agent on hydration, carbonation and strength gain. Cem Concr Compos. 2017;82:152–64. https://doi.org/10.1016/j.cemconcomp.2017.06.006.

Bhagath Singh GVP, Sonat C, Yang EH, Unluer C. Performance of MgO and MgO-SiO2 systems containing seeds under different curing conditions. Cem Concr Compos. 2020;108: 103543. https://doi.org/10.1016/j.cemconcomp.2020.103543.

De Silva P, Bucea L, Sirivivatnanon V. Chemical, microstructural and strength development of calcium and magnesium carbonate binders. Cem Concr Res. 2009;39:460–5. https://doi.org/10.1016/j.cemconres.2009.02.003.

Aphane ME, van der Merwe EM, Strydom CA. Influence of hydration time on the hydration of MgO in water and in a magnesium acetate solution. J Therm Anal Calorim. 2009;96:987–92. https://doi.org/10.1007/s10973-008-9095-y.

Hoang T, Dung NT, Unluer C, Chu J. Use of microbial carbonation process to enable self-carbonation of reactive MgO cement mixes. Cem Concr Res. 2021;143: 106391. https://doi.org/10.1016/j.cemconres.2021.106391.

Dung NT, Unluer C. Development of MgO concrete with enhanced hydration and carbonation mechanisms. Cem Concr Res. 2018;103:160–9. https://doi.org/10.1016/j.cemconres.2017.10.011.

Filippou D, Katiforis N, Papassiopi N, Adam K. On the kinetics of magnesia hydration in magnesium acetate solutions. J Chem Technol Biotechnol. 1999;74:322–8. https://doi.org/10.1002/(sici)1097-4660(199904)74:4%3c322::aid-jctb35%3e3.0.co;2-l.

Dung NT, Unluer C. Performance of reactive MgO concrete under increased CO2 dissolution. Cem Concr Res. 2019;118:92–101. https://doi.org/10.1016/j.cemconres.2019.02.007.

Dung NT, Unluer C. Improving the Carbonation of Reactive MgO Cement Concrete via the Use of NaHCO3 and NaCl. J. Mater. Civ. Eng. 2018;30:(12). https://doi.org/10.1061/(asce)mt.1943-5533.0002509.

Dung NT, Unluer C. Improving the performance of reactive MgO cement-based concrete mixes. Constr Build Mater. 2016;126:747–58. https://doi.org/10.1016/j.conbuildmat.2016.09.090.

Falini G. Albeck S, Weiner S, Addadi L. Control of Aragonite or Calcite Polymorphism by Mollusk Shell Macromolecules, Sci. 1996;271:67–69. https://doi.org/10.1126/science.271.5245.67.

Khan RI, Ashrafa W, Olek J. Amino acids as performance-controlling additives in carbonation-activated cementitious materials. Cem Concr Res. 2021;147: 106501. https://doi.org/10.1016/j.cemconres.2021.106501.

Colfen H. Precipitation of carbonates: recent progress in controlled production of complex shapes. Curr Opin Colloid Interface Sci. 2003;8:23–31. https://doi.org/10.1016/S1359-0294(03)00012-8.

Štajner L, Kontrec J, Dzˇakula BN, Maltar-Strmecˇki N, Plodinec M, Lyons DM, Kralj D. The effect of different amino acids on spontaneous precipitation of calcium carbonate polymorphs. J Cryst Growth. 2018;486:71–81. https://doi.org/10.1016/j.jcrysgro.2018.01.023.

Khan RI, Haque MI, Ashrafa W, Shah S, Saleh N. Role of biopolymers in enhancing multiscale characteristics of carbonation-cured cementitious composites. Cem Concr Compos. 2022;134: 104766. https://doi.org/10.1016/j.cemconcomp.2022.104766.

Kim S, Park CB. Dopamine-Induced mineralization of calcium carbonate vaterite microspheres. Langmuir. 2010;26:14730–6. https://doi.org/10.1021/la1027509.

Liu Z, Qu S, Zheng X, **ong X, Fu R, Tang K. Effect of polydopamine on the biomimetic mineralization of mussel-inspired calcium phosphate cement in vitro. Mater Sci Eng C. 2014;44:44–51. https://doi.org/10.1016/j.msec.2014.07.063.

Soroushian P, Won JP, Hassan M. Durability characteristics of CO2-cured cellulose fiber reinforced cement composites. Constr Build Mater. 2012;34:44–53. https://doi.org/10.1016/j.conbuildmat.2012.02.016.

Peters SJ, Rushing TS, Landis EN, Cummins TK. Nanocellulose and Microcellulose Fibers for Concrete. Transp Res Rec 2010;25–28. https://doi.org/10.3141/2142-04.

Choi H, Choi YC. Setting characteristics of natural cellulose fiber reinforced cement composite. Constr Build Mater. 2021;271: 121910. https://doi.org/10.1016/j.conbuildmat.2020.121910.

Li Z, Qian J, Qin J, Hua Y, Yue Y, Tang H. Cementitious and hardening properties of magnesia (MgO) under ambient curing conditions. Cem Concr Res. 2023;170: 107184. https://doi.org/10.1016/j.cemconres.2023.107184.

Li Z, Hua Y, Chang Z, Yue Y, Qin J, Qian J. Hydration, carbonation and strength development of reactive MgO cement blended with lime (CaO) under different curing conditions. J Build. 2023;76: 107082. https://doi.org/10.1016/j.jobe.2023.107082.

Chinese Standard JC/T958–2005, Flow table for determine mortar fluidity. https://www.chinesestandard.net/PDF/English.aspx/JCT958-2005, 2005.

Snellings R, Bazzoni A, Scrivener K. The existence of amorphous phase in portland cements: Physical factors affecting Rietveld quantitative phase analysis. Cem Concr Res. 2014;59:139–46. https://doi.org/10.1016/j.cemconres.2014.03.002.

Wang Y, Gao L. Effect of amino acid retarder on hydration of desulfurized gypsum. New. Build. Mater. 2017;21–23. https://doi.org/10.3969/j.issn.1001-702X.2017.07.006.

Jian S, Zhi L, Zhou H, Ma B. The effect of casein on the masonry mortar and the performance of hardened mixture. New. Build. Mater. 2014;8–11. https://doi.org/10.3969/j.issn.1001-702X.2014.08.003.

Mármol G, Mattoso L, Correa AC, Fioroni CA, Jr HS. Influence of cellulose pulp on the hydration followed by fast carbonation of MgO-based binders. J. CO2. Util. 2020;41:101236. https://doi.org/10.1016/j.jcou.2020.101236.

Ming DW, Franklin WT. Synthesis and characterization of lansfordite and nesquehonite. Soil Sci Soc Am J. 1985;49:1303–8. https://doi.org/10.2136/sssaj1985.03615995004900050046x.

Wang J, Yao S. Study on simulated biomineralization of calcium carbonate in chitosan - amino acid system. Chinese J Inorg Chem. 2002;3:249–54.

Qiao L, Feng Q. Study on self-assembly morphologies of various crystal forms of calcium carbonate under the action of amino acids. Bull Mineral Petrol Geochemistry. 2007;26:118–20.

Smithson GL, Bakhshi NN. Kinetics and mechanism of carbonation of magnesium oxide slurries. Ind Eng Chem Process Des Develop. 1973;12:99–106. https://doi.org/10.1021/i260045a019.

Hay R, Celik K. Enhancing carbonation of magnesium oxide (MgO) cement (RMC)-based composites with calcined limestone. Cem. 2022;9: 100037. https://doi.org/10.1016/j.cement.2022.100037.

Dung NT, Unluer C. Influence of nucleation seeding on the performance of carbonated MgO formulations. Cem Concr Res. 2017;83:1–9. https://doi.org/10.1016/j.cemconcomp.2017.07.005.

Ruan S, Unluer C. Influence of mix design on the carbonation, mechanical properties and microstructure of reactive MgO cement-based concrete. Cem Concr Compos. 2017;80:104–14. https://doi.org/10.1016/j.cemconcomp.2017.03.004.

Vágvölgyi V, Frost RL, Hales M, Locke A, Kristóf J, Horváth E. Controlled rate thermal analysis of hydromagnesite. J Therm Anal Calorim. 2008;92:893–7. https://doi.org/10.1007/s10973-007-8845-6.

Ren H, Chen Z, Wu Y, Yang M, Chen J, Hu H, Liu J. Thermal characterization and kinetic analysis of nesquehonite, hydromagnesite, and brucite, using TG–DTG and DSC techniques. J Therm Anal Calorim. 2014;115:1949–60. https://doi.org/10.1007/s10973-013-3372-0.

Ren H, Chen Z, Dang J, Wu L, Yang D, Chen J, Sheng H. TG-DTG and FTIR methods to study the heat of magnesium carbonate hydrate. J T Univ Technol 2013;44(5). https://doi.org/10.3969/j.issn.1007-9432.2013.05.003.

Lo Y, Lee HM. Curing effects on carbonation of concrete using a phenolphthalein indicator and Fourier-transform infrared spectroscopy. Build Environ. 2002;37:507–14. https://doi.org/10.1016/S0360-1323(01)00052-X.

Frost RL, Palmer SJ. Infrared and infrared emission spectroscopy of nesquehonite Mg (OH)(HCO3) ·2H2O-implications for the formula of nesquehonite. Spectrochim Acta A Mol Biomol. 2011;78:1255–60. https://doi.org/10.1016/j.saa.2010.12.059.

Fruhwirth O, Herzog GW, Hollerer I, Rachetti A. Dissolution and hydration kinetics of MgO. Surf Technol. 1985;24:301–17. https://doi.org/10.1016/0376-4583(85)90080-9.

Wu G. Amino acids: Chemistry and classification, Encyclopedia of Human Nutrition (Fourth Ed). United States. 2023;pp:10–22.

**e A, Shen Y, Zhang C, Yuan Z, Zhu X, Yang Y. Crystal growth of calcium carbonate with various morphologies in different amino acid systems. J Cryst Growth. 2005;285:436–43. https://doi.org/10.1016/j.jcrysgro.2005.08.039.

Acknowledgements

The authors gratefully acknowledge support from National Natural Science Foundation of China Regional Innovation and Development Joint Fund (U22A20126), Science and Technology Innovation Support Plan for Young Researchers in Institutes of Higher Education in Shandong, Natural Science Foundation of Shandong Province (ZR2020YQ33), and the Taishan Scholars Program (tsqn202211170).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, H., Cai, T., Liang, S. et al. Improving the Hydration and Carbonation of Reactive MgO Cement with Amino Acids and the Influencing Mechanisms. J Therm Anal Calorim (2024). https://doi.org/10.1007/s10973-024-13092-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10973-024-13092-w