Abstract

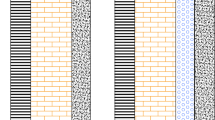

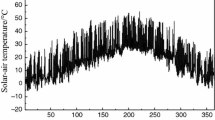

In this study, the effects of using hybrid PCM inside the wall on reducing heat transfer have been examined during the hottest (July) and coldest months (January) in three climate zones. The base wall thickness was 20 cm, and PCM-based wall thickness was considered to be 22 cm. The PCM was placed in two separate layers of 1 cm within the wall. The objective function was to diminish the heat transfer from the PCM-base wall, as compared to the base wall. In all three climatic zones, in warm and cold months, PCM loading into the wall leads to heat transfer reduction. Based on numerical results, in climate zones A (hot summer and mild winter), B (mild summer and very cold winter) and C (warm summer and cold winter) owing to using hybrid PCM layers, heat transfer diminished by 26.9%, 29.65% and 30.5%, respectively.

Similar content being viewed by others

References

Administration EI, Office GP. International Energy Outlook 2016, with Projections to 2040. Government Printing Office; 2016.

Yan S-R, Fazilati MA, Samani N, Ghasemi HR, Toghraie D, Nguyen Q, et al. Energy efficiency optimization of the waste heat recovery system with embedded phase change materials in greenhouses: a thermo-economic-environmental study. J Energy Storage. 2020;30:101445. https://doi.org/10.1016/j.est.2020.101445.

Li ZX, Al-Rashed AAAA, Rostamzadeh M, Kalbasi R, Shahsavar A, Afrand M. Heat transfer reduction in buildings by embedding phase change material in multi-layer walls: effects of repositioning, thermophysical properties and thickness of PCM. Energy Convers Manag. 2019;195:43–56. https://doi.org/10.1016/j.enconman.2019.04.075.

Ebadi S, Tasnim SH, Aliabadi AA, Mahmud S. An experimental investigation of the charging process of thermal energy storage system filled with PCM and metal wire mesh. Appl Therm Eng. 2020;174:115266. https://doi.org/10.1016/j.applthermaleng.2020.115266.

Kalbasi R, Afrand M, Alsarraf J, Tran M-D. Studies on optimum fins number in PCM-based heat sinks. Energy. 2019;171:1088–99. https://doi.org/10.1016/j.energy.2019.01.070.

da Cunha SRL, de Aguiar JLB. Phase change materials and energy efficiency of buildings: a review of knowledge. J Energy Storage. 2020;27:101083. https://doi.org/10.1016/j.est.2019.101083.

Khudhair AM, Farid MM. A review on energy conservation in building applications with thermal storage by latent heat using phase change materials. Energy Convers Manag. 2004;45(2):263–75.

Barzin R, Chen JJJ, Young BR, Farid MM. Application of PCM energy storage in combination with night ventilation for space cooling. Appl Energy. 2015;158:412–21. https://doi.org/10.1016/j.apenergy.2015.08.088.

Gounni A, El Alami M. The optimal allocation of the PCM within a composite wall for surface temperature and heat flux reduction: an experimental approach. Appl Therm Eng. 2017;127:1488–94. https://doi.org/10.1016/j.applthermaleng.2017.08.168.

Xu T, Chen Q, Zhang Z, Gao X, Huang G. Investigation on the properties of a new type of concrete blocks incorporated with PEG/SiO2 composite phase change material. Build Environ. 2016;104:172–7. https://doi.org/10.1016/j.buildenv.2016.05.003.

Salimpour MR, Kalbasi R, Lorenzini G. Constructal multi-scale structure of PCM-based heat sinks. Contin Mech Thermodyn. 2017;29(2):477–91.

Irandoost Shahrestani M, Maleki A, Safdari Shadloo M, Tlili I. Numerical investigation of forced convective heat transfer and performance evaluation criterion of Al2O3/water nanofluid flow inside an axisymmetric microchannel. Symmetry. 2020;12(1):120.

Komeilibirjandi A, Raffiee AH, Maleki A, Alhuyi Nazari M, Safdari ShadlooM. Thermal conductivity prediction of nanofluids containing CuO nanoparticles by using correlation and artificial neural network. J Therm Anal Calorim. 2020;139(4):2679–89. https://doi.org/10.1007/s10973-019-08838-w.

Zheng Y, Shadloo MS, Nasiri H, Maleki A, Karimipour A, Tlili I. Prediction of viscosity of biodiesel blends using various artificial model and comparison with empirical correlations. Renew Energy. 2020;153:1296–306.

Yan S-R, Kalbasi R, Nguyen Q, Karimipour A. Rheological behavior of hybrid MWCNTs-TiO2/EG nanofluid: a comprehensive modeling and experimental study. J Mol Liq. 2020. https://doi.org/10.1016/j.molliq.2020.113058.

Yan S-R, Kalbasi R, Nguyen Q, Karimipour A. Sensitivity of adhesive and cohesive intermolecular forces to the incorporation of MWCNTs into liquid paraffin: experimental study and modeling of surface tension. J Mol Liq. 2020. https://doi.org/10.1016/j.molliq.2020.113235.

Tian X-X, Kalbasi R, Qi C, Karimipour A, Huang H-L. Efficacy of hybrid nano-powder presence on the thermal conductivity of the engine oil: an experimental study. Powder Technol. 2020. https://doi.org/10.1016/j.powtec.2020.05.004.

Yang L, Huang J-n, Zhou F. Thermophysical properties and applications of nano-enhanced PCMs: an update review. Energy Convers Manag. 2020;214:112876. https://doi.org/10.1016/j.enconman.2020.112876.

Chou H-M, Chen C-R, Nguyen V-L. A new design of metal-sheet cool roof using PCM. Energy Build. 2013;57:42–50. https://doi.org/10.1016/j.enbuild.2012.10.030.

Zhou G, Zhang Y, Zhang Q, Lin K, Di H. Performance of a hybrid heating system with thermal storage using shape-stabilized phase-change material plates. Appl Energy. 2007;84(10):1068–77. https://doi.org/10.1016/j.apenergy.2006.09.015.

** X, Medina MA, Zhang X. On the importance of the location of PCMs in building walls for enhanced thermal performance. Appl Energy. 2013;106:72–8. https://doi.org/10.1016/j.apenergy.2012.12.079.

Liu C, Wu Y, Zhu Y, Li D, Ma L. Experimental investigation of optical and thermal performance of a PCM-glazed unit for building applications. Energy Build. 2018;158:794–800. https://doi.org/10.1016/j.enbuild.2017.10.069.

Zhou D, Eames P. Phase Change Material Wallboard (PCMW) melting temperature optimisation for passive indoor temperature control. Renew Energy. 2019;139:507–14. https://doi.org/10.1016/j.renene.2019.02.109.

Saxena R, Rakshit D, Kaushik SC. Phase change material (PCM) incorporated bricks for energy conservation in composite climate: a sustainable building solution. Sol Energy. 2019;183:276–84. https://doi.org/10.1016/j.solener.2019.03.035.

Bahrar M, Djamai ZI, El Mankibi M, Si Larbi A, Salvia M. Numerical and experimental study on the use of microencapsulated phase change materials (PCMs) in textile reinforced concrete panels for energy storage. Sustain Cities Soc. 2018;41:455–68. https://doi.org/10.1016/j.scs.2018.06.014.

Castell A, Martorell I, Medrano M, Pérez G, Cabeza LF. Experimental study of using PCM in brick constructive solutions for passive cooling. Energy Build. 2010;42(4):534–40. https://doi.org/10.1016/j.enbuild.2009.10.022.

Cunha S, Aguiar JB, Tadeu A. Thermal performance and cost analysis of mortars made with PCM and different binders. Constr Build Mater. 2016;122:637–48. https://doi.org/10.1016/j.conbuildmat.2016.06.114.

Kuznik F, Virgone J, Roux J-J. Energetic efficiency of room wall containing PCM wallboard: a full-scale experimental investigation. Energy Build. 2008;40(2):148–56. https://doi.org/10.1016/j.enbuild.2007.01.022.

Cabeza LF, Castell A, Barreneche C, de Gracia A, Fernández AI. Materials used as PCM in thermal energy storage in buildings: a review. Renew Sustain Energy Rev. 2011;15(3):1675–95. https://doi.org/10.1016/j.rser.2010.11.018.

Waqas A, Ud DinZ. Phase change material (PCM) storage for free cooling of buildings—a review. Renew Sustain Energy Rev. 2013;18:607–25. https://doi.org/10.1016/j.rser.2012.10.034.

Li J, Mohammadi A, Maleki A. Techno-economic analysis of new integrated system of humid air turbine, organic Rankine cycle, and parabolic trough collector. J Therm Anal Calorim. 2020;139(4):2691–703.

Maleki A, Elahi M, Assad MEH, Nazari MA, Shadloo MS, Nabipour N. Thermal conductivity modeling of nanofluids with ZnO particles by using approaches based on artificial neural network and MARS. J Therm Anal Calorim. 2020. https://doi.org/10.1007/s10973-020-09373-9.

Wang N, Maleki A, Alhuyi Nazari M, Tlili I, Safdari ShadlooM. Thermal conductivity modeling of nanofluids contain MgO particles by employing different approaches. Symmetry. 2020;12(2):206.

Tian M-W, Ebadi AG, Jermsittiparsert K, Kadyrov M, Ponomarev A, Javanshir N, et al. Risk-based stochastic scheduling of energy hub system in the presence of heating network and thermal energy management. Appl Therm Eng. 2019;159:113825. https://doi.org/10.1016/j.applthermaleng.2019.113825.

Tian M-W, Yan S-R, Tian X-X, Nojavan S, Jermsittiparsert K. Risk and profit-based bidding and offering strategies for pumped hydro storage in the energy market. J Clean Prod. 2020;256:120715. https://doi.org/10.1016/j.jclepro.2020.120715.

Tian M-W, Yuen H-C, Yan S-R, Huang W-L. The multiple selections of fostering applications of hydrogen energy by integrating economic and industrial evaluation of different regions. Int J Hydrog Energy. 2019;44(56):29390–8. https://doi.org/10.1016/j.ijhydene.2019.07.089.

Handbook AF. American society of heating, refrigerating and air-conditioning engineers. Inc: Atlanta. 2009.

Tiwari G, Tiwari A. Handbook of solar energy. Berlin: Springer; 2006.

Yeoh GH, Tu J. Chapter 3—Solution methods for multiphase flows. In: Yeoh GH, Tu J, editors. Computational techniques for multiphase flows. 2nd ed. Oxford: Butterworth-Heinemann; 2019. p. 85–226.

Pasupathy A, Athanasius L, Velraj R, Seeniraj RV. Experimental investigation and numerical simulation analysis on the thermal performance of a building roof incorporating phase change material (PCM) for thermal management. Appl Therm Eng. 2008;28(5):556–65. https://doi.org/10.1016/j.applthermaleng.2007.04.016.

Kalbasi R, Izadi F, Talebizadehsardari P. Improving performance of AHU using exhaust air potential by applying exergy analysis. J Therm Anal Calorim. 2020. https://doi.org/10.1007/s10973-019-09198-1.

Yari M, Kalbasi R, Talebizadehsardari P. Energetic–exergetic analysis of an air handling unit to reduce energy consumption by a novel creative idea. Int J Numer Methods Heat Fluid Flow. 2019;29(10):3959–75. https://doi.org/10.1108/HFF-09-2018-0524.

Kalbasi R, Shahsavar A, Afrand M. Incorporating novel heat recovery units into an AHU for energy demand reduction-exergy analysis. J Therm Anal Calorim. 2019. https://doi.org/10.1007/s10973-019-09060-4.

Kalbasi R, Shahsavar A, Afrand M. Reducing AHU energy consumption by a new layout of using heat recovery units. J Therm Anal Calorim. 2019. https://doi.org/10.1007/s10973-019-09070-2.

Kalbasi R, Ruhani B, Rostami S. Energetic analysis of an air handling unit combined with enthalpy air-to-air heat exchanger. J Therm Anal Calorim. 2019. https://doi.org/10.1007/s10973-019-09158-9.

Gholipour S, Afrand M, Kalbasi R. Improving the efficiency of vacuum tube collectors using new absorbent tubes arrangement: introducing helical coil and spiral tube adsorbent tubes. Renew Energy. 2020;151:772–81. https://doi.org/10.1016/j.renene.2019.11.068.

Ahmadi Nadooshan A, Kalbasi R, Afrand M. Perforated fins effect on the heat transfer rate from a circular tube by using wind tunnel: an experimental view. Heat Mass Transf. 2018;54(10):3047–57. https://doi.org/10.1007/s00231-018-2333-3.

Nguyen Q, Naghieh A, Kalbasi R, Akbari M, Karimipour A, Tlili I. Efficacy of incorporating PCMs into the commercial wall on the energy-saving annual thermal analysis. J Therm Anal Calorim. 2020. https://doi.org/10.1007/s10973-020-09713-9.

Acknowledgements

This research is partially supported by Technical Innovation Project of Hubei Province (No. 2017AAA133) and Hubei Superior and Distinctive Discipline Group of Mechatronics and Automobiles (No. XKQ2018002).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, Z., Du, C., Ahmadi, D. et al. Numerical modeling of a hybrid PCM-based wall for energy usage reduction in the warmest and coldest months. J Therm Anal Calorim 144, 1985–1998 (2021). https://doi.org/10.1007/s10973-020-09861-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-020-09861-y