Abstract

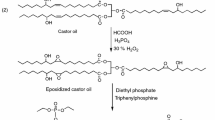

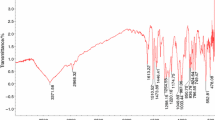

We report here for the first time a chlorinated phosphate ester derived from castor oil (CPCO) for preparing flame-retardant poly(vinyl chloride) (PVC) materials. Flame-retardant PVC materials plasticized with different amount of CPCO were prepared by solvent casting method. The property of flame-retardant PVC materials was investigated with LOI, SEM, TG, TG-FTIR and TG-MS. The results showed that the LOI value of plasticized PVC blends reached 36.3 %. TG-FTIR and TG-MS were used to investigate the pyrolysis products during the thermal degradation process. The nonflammable gases included a few phosphorus-containing compounds, such as P–O–C and P–OH, indicating that more phosphorus-containing compounds were generated during the thermal degradation of CPCO still retained in char residue rather than gas phase, which promoted the formation of high-quality carbon residue. Consolidated and compact structure of carbon residue was produced and covered on the surface of flame-retardant PVC materials, which was effective to prevent the heat flux and air entering PVC matrix, then protected the underlying materials and improved the thermal and flame-retardant performance of PVC materials.

Similar content being viewed by others

References

Silva MAD, Vieira MGA, Maçumoto ACG, Beppu MM. Polyvinylchloride (PVC) and natural rubber films plasticized with a natural polymeric plasticizer obtained through polyesterification of rice fatty acid. Polym Test. 2011;30(5):478–84.

Saeki Y, Emura T. Technical progresses for PVC production. Prog Polym Sci. 2002;27:2055–131.

Lardjane N, Belhaneche-Bensemra N, Massardier V. Migration of new bio-based additives from rigid and plasticized PVC stabilized with epoxidized sunflower oil in soil. J Polym Res. 2013;20:209–19.

Sun T, Thom R. The effect of epoxidized safflower oil on the properties of polyvinyl chloride films. J Elastom Plast. 2010;42(2):129–37.

Palacios OYS, Narvaez Rincon PC, Jean-Pierre Corriou C, Pardo MC, Fonteix C. Low-molecular-weight glycerol esters as plasticizers for poly(vinyl chloride). J Vinyl Addit Technol. 2014;20(2):65–71.

Sander MM, Nicolau A, Guzatto R, Samios D. Plasticiser effect of oleic acid polyester on polyethylene and polypropylene. Polym Test. 2012;31(8):1077–82.

Bueno-Ferrer C, Garrigós MC, Jiménez A. Characterization and thermal stability of poly(vinyl chloride) plasticized with epoxidized soybean oil for food packaging. Polym Degrad Stab. 2012;95:2207–12.

Karmalm P, Hjertberg T, Jansson A, Dahl R. Thermal stability of poly(vinyl chloride) with epoxidized soybean oil as primary plasticizer. Polym Degrad Stab. 2009;94:2275–81.

Yiqun F, Qingwen W, **aoyan B, Weihong W, Cooper PA. Thermal and burning properties of wood flour-poly (vinyl chloride) composite. J Therm Anal Calorim. 2012;109:1577–85.

Hongqiang Q, Weihong W, Hongjuan W, Jixing X, Jianzhong X. Study on the effects of flame retardants on the thermal decomposition of wood by TG-MS. J Therm Anal Calorim. 2011;103:935–42.

Tansir A, Alshehri MS. Thermal degradation and evolved gas analysis of thiourea-formaldehyde resin (TFR) during pyrolysis and combustion. J Therm Anal Calorim. 2012;109:1039–47.

**e W, Pan WP. Thermal characterization of materials using evolved gas analysis. J Therm Anal Calorim. 2001;65:669–85.

Liu CG, Jun L, Wen L, Zhou YH. Development of biobased unsaturated polyester resin containing highly functionalized castor oil. Ind Crop Prod. 2014;52:329–37.

Zhang LQ, Zhang M, Zhou YH, Hu LH. The study of mechanical behavior and flame retardancy of castor oil phosphate-based rigid polyurethane foam composites containing expanded graphite and triethyl phosphate. Polym Degrad Stab. 2013;98:2784–94.

Zhang LQ, Zhang M, Hu LH, Zhou YH. Synthesis of rigid polyurethane foams with castor oil-based flame retardant polyols. Ind Crop Prod. 2014;52:380–8.

Jia P, Zhang M, Hu L, Bo C, Zhou Y. Thermal degradation and flame retardant mechanism of poly(vinyl chloride) plasticized with a novel chlorinated phosphate based on soybean oil. Thermochim Acta 2015;613:113–120.

Pan LL, Li GY, Su YC, Lian JS. Fire retardant mechanism analysis between ammonium polyphosphate and triphenyl phosphate in unsaturated polyester resin. Polym Degrad Stab. 2012;97:1801–6.

Ying-Ling L, Yie-Chan C, Tsung-Yu C. Phosphorus-containing polyaryloxydiphenylsilanes with high flame retardance arising from a phosphorus–silicon synergistic effect. Polym Int. 2003;52:1256–61.

Ye L, Wu Q, Qu B. Synergistic effects and mechanism of multiwalled carbon nanotubes with magnesium hydroxide in halogen-free flame retardant EVA/MH/MWNT nanocomposites. Polym Degrad Stab. 2009;94:751–6.

Sun T, Thom R. The effect of epoxidized safflower oil on the properties of polyvinyl chloride films. J Elastom Plast. 2010;42(2):129–37.

Yao Q, Wilkie CA. Thermal degradation of PVC in the presence of polystyrene. J Vinyl Addit Technol. 2001;7(1):26–36.

Soudais Y, Moga L, Blazek J, Lemort F. Coupled DTA–TGA–FT-IR investigation of pyrolytic decomposition of EVA, PVC and cellulose. J Anal Appl Pyrolysis. 2007;78(1):45–57.

Qu H, Liu X, Xu J, Ma HY, Jiao Y, **e J. Investigation on thermal degradation of poly(1,4-butylene therphthalate) filled with aluminum hypophosphite and trimer by thermogravimetric analysis-fourier transform infrared spectroscopy and thermogravimetric analysis-mass spectroscopy. Ind Eng Chem. 2014;53:8476–83.

Levchik SV, Weil ED. A review on thermal decomposition and combustion of thermoplastic polyesters. Polym Adv Technol. 2004;15:691–700.

Botelho G, Queiro’s A, Liberal S, Gijsman P. Studies on thermal and thermo-oxidative degradation of poly(ethylene terephthalate) and poly(butylene terephthalate). Polym Degrad Stab. 2001;74:39–48.

Balabanovich AI, Zevaco TA, Schnabel W. Fire retardance in poly(butylene terephthalate). The effects of red phosphorus and radiation-induced cross-links. Macromol Mater Eng. 2004;289:181–90.

Balabanovich AI. Thermal decomposition study of intumescent additives: pentaerythritol phosphate and its blend with melamine phosphate. Thermochim Acta. 2005;435:188–96.

Acknowledgements

This work was supported by National 12th Five-year Science and Technology Support Plan (Grant No. 2015BAD15B08), Jiangsu Province Natural Science Foundation of China (Grant No. BK20141074).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jia, P., Hu, L., Zhang, M. et al. TG-FTIR and TG-MS analysis applied to study the flame retardancy of PVC–castor oil-based chlorinated phosphate ester blends. J Therm Anal Calorim 124, 1331–1339 (2016). https://doi.org/10.1007/s10973-015-5199-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-015-5199-3