Abstract

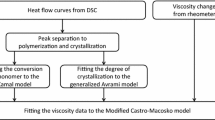

This publication highlights the effect of aramid pulp (1 wt.%) on equilibrium swelling, enthalpy reaction, solid viscoelastic properties, and rheokinetics of castor oil (CO) and polyether (PE) polyol blend (50/50 CO/PE) with polymeric isocyanate (pMDI). The CO-pMDI system showed a lower solubility parameter difference (Δδi) than the PE-pMDI and CO/PE-pMDI. Crosslink density values \({v}_{e}\) are higher for CO-pMDI, and when added to aramid pulp, there is a slight increase due to the possible restriction of swollen volume. Regarding the pseudo-solid behavior, AP restricts the macromolecular movement and confers reinforcing characteristics to PU systems. The Prout–Tompkins autocatalytic model satisfactorily described the reactions, resulting in activation energy values Ea within 45 − 54 kJ/mol. However, for the CO/PE blend, the difference between the reactivity of the polyols and the solubility parameter with pMDI results in a two-step reaction kinetics. Aramid pulp practically does not change the reaction mechanism, only the viscosity of the medium. Furthermore, the thermodynamic parameters (ΔS* and ΔH*) indicated that the PU with AP resulted in more ordered complexes. The adequate description of the polymerization reaction and the effect of the aramid pulp allowed for obtaining PU formulations with tunable characteristics for strict composite processing composites.

Similar content being viewed by others

Data availability

The raw data needed to reproduce these findings can be shared if the authors request.

References

Pearson A, Naguib HE (2017) Novel polyurethane elastomeric composites reinforced with alumina, aramid, and poly(p-phenylene-2,6-benzobisoxazole) short fibers, development and characterization of the thermal and dynamic mechanical properties. Compos Part B Eng 122:192–201. https://doi.org/10.1016/j.compositesb.2017.04.017

Mihail L (2005) Chemistry and Technology of Polyols for Polyurethanes, 1st ed. British Library., Shawbury, Shrewsbury, Shropshire

Akindoyo JO, Beg MDH, Ghazali S et al (2016) Polyurethane types, synthesis and applications-a review. RSC Adv 6:114453–114482. https://doi.org/10.1039/c6ra14525f

Wang C, Dai L, Yang Z et al (2018) Reinforcement of castor oil-based polyurethane with surface modification of attapulgite. Polymers (Basel) 10:1–11. https://doi.org/10.3390/polym10111236

Kerche EF, da Silva VD, da Silveira JG et al (2021) Aramid pulp treated with imidazolium ionic liquids as a filler in rigid polyurethane bio-foams. J Appl Polym Sci. https://doi.org/10.1002/app.50492

Denchev Z, Dencheva N (2012) Manufacturing and Properties of Aramid Reinforced Composites. First Edit. Carl Hanser Verlag GmbH & Co, KG

Andreopoulos AG, Konstantinidou AV, Petsalas HJ (1989) Elastomeric polyurethanes reinforced with aramid fibers. J Appl Polym Sci 38:2073–2078. https://doi.org/10.1002/app.1989.070381109

Lipatov YS, Kosyanchuk LV, Nesterov AE, Antonenko OI (2003) Filler effect on polymerization kinetics and phase separation in polymer blends formed in situ. Polym Int 52:664–669. https://doi.org/10.1002/pi.937

Macosko CW (1985) Rheological Changes During Crosslinking. Br Polym J 17:239–245. https://doi.org/10.1002/pi.4980170228

Lipshitz SD, Macosko CW (1976) Rheological Changes During a Urethane Network Polymerization. Polym Eng Sci. https://doi.org/10.1002/pen.760161205

Li J, Jiang S, Ding L, Wang L (2021) Reaction kinetics and properties of MDI base poly (urethane-isocyanurate) network polymers. Des Monomers Polym 24:265–273. https://doi.org/10.1080/15685551.2021.1971858

Lucio B, de la Fuente JL (2021) Chemorheology and Kinetics of High-Performance Polyurethane Binders Based on HMDI. Macromol Mater Eng. https://doi.org/10.1002/mame.202000617

Agnol LD, Dias FTG, Nicoletti NF et al (2019) Polyurethane tissue adhesives for annulus fibrosus repair: Mechanical restoration and cytotoxicity. J Biomater Appl 34:673–686. https://doi.org/10.1177/0885328219864901

Santhosh G, Reshmi S, Reghunadhan Nair CP (2020) Rheokinetic characterization of polyurethane formation in a highly filled composite solid propellant. J Therm Anal Calorim 140:213–223. https://doi.org/10.1007/s10973-019-08793-6

Lucio B, De La Fuente JL (2016) Kinetic and thermodynamic analysis of the polymerization of polyurethanes by a rheological method. Thermochim Acta 625:28–35. https://doi.org/10.1016/j.tca.2015.12.012

Dall Agnol L, Ornaghi HL, Monticeli F et al (2021) Polyurethanes synthetized with polyols of distinct molar masses: Use of the artificial neural network for prediction of degree of polymerization. Polym Eng Sci 61:1810–1818. https://doi.org/10.1002/pen.25702

Lucio B, de la Fuente JL (2018) Kinetic and chemorheological modelling of the polymerization of 2,4- Toluenediisocyanate and ferrocene-functionalized hydroxyl-terminated polybutadiene. Polymer (Guildf) 140:290–303. https://doi.org/10.1016/j.polymer.2018.02.058

Lucio B, De La Fuente JL (2014) Rheological cure characterization of an advanced functional polyurethane. Thermochim Acta 596:6–13. https://doi.org/10.1016/j.tca.2014.09.012

Pacheco MFM, Bianchi O, Fiorio R et al (2009) Thermal, chemical, and morphological characterization of microcellular polyurethane elastomers. J Elastomers Plast 41:323–338. https://doi.org/10.1177/0095244309095016

Kraus G (1963) Swelling of filler-reinforced vulcanizates. J Appl Polym Sci 7:861–871. https://doi.org/10.1002/app.1963.070070306

Valentini L, Bittolo Bon S, Hernández M et al (2018) Nitrile butadiene rubber composites reinforced with reduced graphene oxide and carbon nanotubes show superior mechanical, electrical and icephobic properties. Compos Sci Technol 166:109–114. https://doi.org/10.1016/j.compscitech.2018.01.050

Echeverria-Altuna O, Ollo O, Calvo-Correas T et al (2022) Effect of the catalyst system on the reactivity of a polyurethane resin system for RTM manufacturing of structural composites. Express Polym Lett 16:234–247. https://doi.org/10.3144/expresspolymlett.2022.19

Younes UE (2018) Polyurethane composites produced by a vacuum infusion process. Patent 1:1–12

Hansen CM (2007) Hansen solubility parameters: A user’s handbook: Second edition, Second Edi. CRC, London

Meaurio E, Sanchez-Rexach E, Zuza E et al (2017) Predicting miscibility in polymer blends using the Bagley plot: Blends with poly(ethylene oxide). Polymer (Guildf) 113:295–309. https://doi.org/10.1016/j.polymer.2017.01.041

Hesekamp D, Pahl MH (1996) Curing effects on viscosity of reactive epoxy resin adhesives. Rheol Acta 35:321–328. https://doi.org/10.1007/BF00403532

Opfermann J (2000) Kinetic analysis using multivariate non-linear regression. I. Basic concepts. J Therm Anal Calorim 60:641–658. https://doi.org/10.1023/A:101016762655

Opfermann J (2011) Temperature dependence of viscosity of a material without cross-linking. 11

Hesekamp D, Broecker HC, Pahl MH (1998) Chemo-Rheology of Cross-Linking Polymers. Chem Eng Technol 21:149–153. https://doi.org/10.1002/(SICI)1521-4125(199802)21:2%3c149::AID-CEAT149%3e3.0.CO;2-P

Flammersheim HJ, Opfermann J (1999) Formal kinetic evaluation of reactions with partial diffusion control. Thermochim Acta 337:141–148. https://doi.org/10.1016/S0040-6031(99)00162-8

Ourique PA, Ornaghi FG, Ornaghi HL et al (2019) Thermo-oxidative degradation kinetics of renewable hybrid polyurethane–urea obtained from air-oxidized soybean oil. J Therm Anal Calorim. https://doi.org/10.1007/s10973-019-08089-9

Eyring H (1935) The activated complex in chemical reactions. J Chem Phys 3:63–71. https://doi.org/10.1063/1.1749604

Avery HE (1974) Basic reaction kinetics and mechanisms. Macmilllan Education, London

Boudouris D, Constantinou L, Panayiotou C (1997) A group contribution estimation of the thermodynamic properties of polymers †. Ind Eng Chem Res. https://doi.org/10.1021/ie970242g

Ruzette A-VG, Mayes AM (2001) A simple free energy model for weakly interacting polymer blends. Macromolecules. https://doi.org/10.1021/ma000712

Van Krevelen DW, Te Nijenhuis K (2009) Properties of Polymers - Their correlation with chemical structure; their numerical estimation and prediction from additive group contributions, 4 edition. New York

Miyajima T, Nishiyama K, Satake M, Tsuji T (2015) Synthesis and process development of polyether polyol with high primary hydroxyl content using a new propoxylation catalyst. Polym J 47:771–778. https://doi.org/10.1038/pj.2015.64

Chattopadhyay DK, Raju KVSN (2007) Structural engineering of polyurethane coatings for high performance applications. Prog Polym Sci 32:352–418. https://doi.org/10.1016/j.progpolymsci.2006.05.003

Ismail TNMT, Palam KDP, Bakar ZBA et al (2016) Urethane-forming reaction kinetics and catalysis of model palm olein polyols: Quantified impact of primary and secondary hydroxyls. J Appl Polym Sci. https://doi.org/10.1002/app.42955

Caraculacu AA, Coseri S (2001) Isocyanates in polyaddition processes. Structure and reaction mechanisms. Prog Polym Sci 26:799–851. https://doi.org/10.1016/S0079-6700(00)00033-2

Formela K, Hejna A, Piszczyk Ł et al (2016) Processing and structure–property relationships of natural rubber/wheat bran biocomposites. Cellulose 23:3157–3175. https://doi.org/10.1007/s10570-016-1020-0

Olejnik A, Gosz K, Piszczyk Ł (2020) Kinetics of cross-linking processes of fast-curing polyurethane system. Thermochim Acta 683:178435. https://doi.org/10.1016/j.tca.2019.178435

Ionescu M, Radojčić D, Wan X et al (2016) Highly functional polyols from castor oil for rigid polyurethanes. Eur Polym J 84:736–749. https://doi.org/10.1016/j.eurpolymj.2016.06.006

Flory PJ (1953) Principles of polymer chemistry, 1°. Fisher, New York

Flory PJ, Rehner J (2004) Statistical mechanics of cross-linked polymer networks I. Rubberlike elasticity. J Chem Phys 11:512–520. https://doi.org/10.1063/1.1723792

Šesták J (2017) Šesták-Berggren equation: now questioned but formerly celebrated—what is right: Commentary on the Burnham paper on logistic equations in kinetics. J Therm Anal Calorim 127:1117–1123. https://doi.org/10.1007/s10973-015-4998-x

Okhawilai M, Parnklang T, Mora P et al (2019) The energy absorption enhancement in aramid fiber-reinforced poly(benzoxazine-co-urethane) composite armors under ballistic impacts. J Reinf Plast Compos 38:133–146. https://doi.org/10.1177/0731684418808894

Elaheh K, Vahid H-A, Farshad BA, Jafar H (2019) Aramid fibers composites to innovative sustainable materials for biomedical applications. In: Materials for Biomedical Engineering. Tehran - Iran, pp 173–204

Szycher M (1999) Handbook of polyurethane, 1st edn. CRC Press, New York

Shen CH, Springer GS (1976) Moisture absorption and desorption of composite materials. J Compos Mater 10:2–20. https://doi.org/10.1177/002199837601000101

Quintanilha RC, Orth ES, Grein-Iankovski A et al (2014) The use of gum Arabic as “Green” stabilizer of poly(aniline) nanocomposites: A comprehensive study of spectroscopic, morphological and electrochemical properties. J Colloid Interface Sci 434:18–27. https://doi.org/10.1016/j.jcis.2014.08.006

Fernandez d’Arlas B, Rueda L, Stefani PM et al (2007) Kinetic and thermodynamic studies of the formation of a polyurethane based on 1,6-hexamethylene diisocyanate and poly(carbonate-co-ester)diol. Thermochim Acta 459:94–103. https://doi.org/10.1016/j.tca.2007.03.021

Bazzo A, Dias SLP, Vaghetti JCP et al (2021) Caesalpinia ferrea: a potential feedstock for biochar production. Biomass Convers Biorefinery. https://doi.org/10.1007/s13399-021-02068-7

Acknowledgements

The authors acknowledge Brazilian Agency Coordenação de Aperfeiçoamento de Pessoal de Nível Superior (CAPES, Brazil)—(Finance Code 001) and Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq, Brazil) (grants 305814/2021-4). The authors also thank the projects STINT/CAPES N° 88881.304743/2018-01 and CNPq N°408193/2021-2.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Competing interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this research paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Cruz, J.A., Amico, S.C. & Bianchi, O. Effect of the aramid pulp on the physicochemical, viscoelastic properties and rheokinetics of polyurethanes. J Polym Res 30, 12 (2023). https://doi.org/10.1007/s10965-022-03393-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-022-03393-9