Abstract

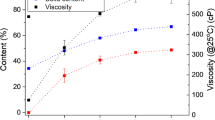

Two potential hazardous substance problems are urgent to be solved. (1) Urea–formaldehyde resin waste that may produce various toxic compounds during conventional treatment; (2) Toxic heavy metal ions released in water that pose a severe threat to human health and ecosystems. Herein, innovative conversion of urea–formaldehyde resin waste into an effective adsorbent for hazardous heavy metal ions was achieved by a simple degradation–repolymerization method, toward a circular materials economy approach. The detailed effects of temperature and time on the degradation efficiency were studied. Plausible degradation mechanism was proposed. To increase the adsorption performance, the challenge of affording urea–formaldehyde resins with three-dimensional network structures was overcome by the ice templating. The effects of cooling rate and added water content on the morphology of urea–formaldehyde resin were investigated. Due to its three-dimensional network structure and high amine density, the prepared adsorbent exhibited removal rate up to 95.68% for Pb(II) and 80.80% for Cu(II), much higher than untreated urea–formaldehyde resin waste. The effect of solution pH on the adsorption performance of heavy metal ions was also discussed. Moreover, after five cycles, removal rates were still up to 81.34% for Pb(II) and 64.37% for Cu(II), indicating its good cycle stability. Its large source of raw materials, convenient conversion method, and high removal rate make this method extremely competitive in the areas of both polymer degradation and heavy metal ion removal.

Similar content being viewed by others

References

Salthammer T, Mentese S, Marutzky R (2010) Formaldehyde in the indoor environment. Chem Rev 110:2536–2572

Sun M (1984) Formaldehyde issue: back to square one. Science 224:968–969

Marvel CS, Elliott JR (1946) The structure of urea-formaldehyde resins. J Am Chem Soc 68:1681–1686

Babich MA (1998) Risk assessment of low-level chemical exposures from consumer products under the U.S. Consumer Product Safety Commission chronic hazard guidelines. Environ Health Perspect 106:387–390

Harris JC, Rumack BH (1981) Toxicology of urea formaldehyde and toxicology of urea formaldehyde and polyurethane foam insulation. JAMA 245:243–246

Zhan L, Jiang L, Zhang Y, Gao B, Xu Z (2020) Reduction, detoxification and recycling of solid waste by hydrothermal technology: a review. Chem Eng J 390:124651

Shi R, Zhang Z-Y, Zhang F-S (2018) An efficient approach for spaceflight solid waste treatment: Co-disposal with hazardous medicine by hydrothermal oxidation process. Chem Eng J 349:204–213

Ren T, Wang Y, Wu N, Qing Y, Li X, Wu Y, Liu M (2022) Degradation of urea-formaldehyde resin residues by a hydrothermal oxidation method into recyclable small molecular organics. J Hazard Mater 426:127783

Qian Y, Xu W, Zhan J-H, Jia X, Zhang F (2021) Atomic insights into the thermal runaway process of hydrogen peroxide and 1,3,5-trimethybenzene mixture: combining ReaxFF MD and DFT methods. Process Saf Environ 147:578–588

Jia X, Sun F, Fei Y, ** M, Zhang F, Xu W, Shi N, Lv Z (2018) Explosion characteristics of mixtures containing hydrogen peroxide and working solution in the anthraquinone route to hydrogen peroxide. Process Saf Environ 119:218–222

Liu M, Wang Y, Wu Y, Wan H (2018) Hydrolysis and recycling of urea formaldehyde resin residues. J Hazard Mater 355:96–103

Khonakdar Dazmiri M, Valizadeh Kiamahalleh M, Valizadeh Kiamahalleh M, Mansouri HR, Moazami V (2019) Revealing the impacts of recycled urea–formaldehyde wastes on the physical–mechanical properties of MDF. Eur J Wood Wood Prod 77:293–299

Liu F, Chen X, Liu Y, Niu Z, Tang H, Mao S, Li N, Chen G, **ang H (2021) Serum cardiovascular-related metabolites disturbance exposed to different heavy metal exposure scenarios. J Hazard Mater 415:125590

Long Z, Zhu H, Bing H, Tian X, Wang Z, Wang X, Wu Y (2021) Contamination, sources and health risk of heavy metals in soil and dust from different functional areas in an industrial city of Panzhihua City, Southwest China. J Hazard Mater 420:126638

Sierra I, Pérez-Quintanilla D (2013) Heavy metal complexation on hybrid mesoporous silicas: an approach to analytical applications. Chem Soc Rev 42:3792–3807

Zhang Y, Zhang L, Gao R, Zhong L, Xue J (2021) CaCO3-coated PVA/BC-based composite for the simultaneous adsorption of Cu(II), Cd(II), Pb(II) in aqueous solution. Carbohydr Polym 267:118227

Zhang P, Gong J-L, Zeng G-M, Deng C-H, Yang H-C, Liu H-Y, Huan S-Y (2017) Cross-linking to prepare composite graphene oxide-framework membranes with high-flux for dyes and heavy metal ions removal. Chem Eng J 322:657–666

Wang H, Gao Q, Li H, Wang G, Han B, **a K, Zhou C (2020) Hydrous titania nanosheets constructed hierarchical hollow microspheres as a highly efficient dual-use decontaminant for elimination of heavy metal ions and organic pollutants. Chem Eng J 381:122638

Zhang L, Mu C, Zhong L, Xue J, Zhou Y, Han X (2019) Recycling of Cr (VI) from weak alkaline aqueous media using a chitosan/ triethanolamine/Cu (II) composite adsorbent. Carbohydr Polym 205:151–158

Ahmadijokani F, Molavi H, Rezakazemi M, Tajahmadi S, Bahi A, Ko F, Aminabhavi TM, Li J-R, Arjmand M (2022) UiO-66 metal–organic frameworks in water treatment: a critical review. Prog Mater Sci 125:100904

Pagliaccia B, Carretti E, Severi M, Berti D, Lubello C, Lotti T (2022) Heavy metal biosorption by extracellular polymeric substances (EPS) recovered from anammox granular sludge. J Hazard Mater 424:126661

Kumar R, Barakat MA, Daza YA, Woodcock HL, Kuhn JN (2013) EDTA functionalized silica for removal of Cu(II), Zn(II) and Ni(II) from aqueous solution. J Colloid Interface Sci 408:200–205

Sellaoui L, Hessou EP, Badawi M, Netto MS, Dotto GL, Silva LFO, Tielens F, Ifthikar J, Bonilla-Petriciolet A, Chen Z (2021) Trap** of Ag+, Cu2+, and Co2+ by faujasite zeolite Y: new interpretations of the adsorption mechanism via DFT and statistical modeling investigation. Chem Eng J 420:127712

Li Y, Yu H, Liu L, Yu H (2021) Application of co-pyrolysis biochar for the adsorption and immobilization of heavy metals in contaminated environmental substrates. J Hazard Mater 420:126655

Ma D, Wei J, Zhao Y, Chen Y, Tang S (2020) The removal of uranium using novel temperature sensitive urea-formaldehyde resin: adsorption and fast regeneration. Sci Total Environ 735:139399

Qu P, Li Y, Huang H, Chen J, Yu Z, Huang J, Wang H, Gao B (2020) Urea formaldehyde modified alginate beads with improved stability and enhanced removal of Pb2+, Cd2+, and Cu2+. J Hazard Mater 396:122664

Qu P, Li Y, Huang H, Wu G, Chen J, He F, Wang H, Gao B (2020) Foamed urea-formaldehyde microspheres for removal of heavy metals from aqueous solutions. Chemosphere 241:125004

Li C, Duan H, Wang X, Meng X, Qin D (2015) Fabrication of porous resins via solubility differences for adsorption of cadmium (II). Chem Eng J 262:250–259

Wibowo ES, Park B-D, Causin V (2022) Recent advances in urea-formaldehyde resins: converting crystalline thermosetting polymers back to amorphous ones. Polym Rev 62:722–756

Joukhdar H, Seifert A, Jüngst T, Groll J, Lord MS, Rnjak-Kovacina J (2021) Ice templating soft matter: fundamental principles and fabrication approaches to tailor pore structure and morphology and their biomedical applications. Adv Mater 33:e2100091

Jada SS (1988) The structure of urea–formaldehyde resins. J Appl Polym Sci 35:1573–1592

Li A, Kan C, Du Y, Liu D (2006) Study on the evolvement of structure in synthesis of urea-formaldehyde resins by FTIR. Acta Phys Chim Sin 22:873–877

Chuang IS, Maciel GE (1992) Carbon-13 CP/MAS NMR study of the structural dependence of urea-formaldehyde resins on formaldehyde-to-urea molar ratios at different urea concentrations and pH values. Macromolecules 25:3204–3226

Myers GE (1981) Investigation of urea–formaldehyde polymer cure by infrared. J Appl Polym Sci 26:747–764

Nuryawan A, Park B-D, Singh AP (2014) Comparison of thermal curing behavior of liquid and solid urea–formaldehyde resins with different formaldehyde/urea mole ratios. J Therm Anal Calorim 118:397–404

Park B-D, Kim YS, Singh AP, Lim KP (2003) Reactivity, chemical structure, and molecular mobility of urea–formaldehyde adhesives synthesized under different conditions using FTIR and solid-state 13C CP/MAS NMR spectroscopy. J Appl Polym Sci 88:2677–2687

Xamena FL, Areán CO, Spera S, Merlo E, Zecchina A (2004) Formaldehyde oligomerization on silicalite: an FTIR and NMR study. Catal Lett 95:51–55

Shukla PG, Sivaram S, Mohanty B (1992) Structure and dynamics of starch crosslinked with urea-formaldehyde polymers by carbon-13 CP/MAS NMR spectroscopy. Macromolecules 25:2746–2751

Taylor R, Pragnell RJ, McLaren JV, Snape CE (1982) Evaluation of NMR spectroscopy for the quantitative characterization of urea—formaldehyde resins. Talanta 29:489–494

Steinhof O, Kibrik ÉJ, Scherr G, Hasse H (2014) Quantitative and qualitative 1H, 13C, and 15N NMR spectroscopic investigation of the urea-formaldehyde resin synthesis. Magn Reson Chem 52:138–162

Wang F, Wang Y, Fang Y, Zhu J, Li X, Qi J, Wu W (2020) Synthesis of nitrogen-doped flower-like carbon microspheres from urea-formaldehyde resins for high-performance supercapacitor. J Alloys Compds 812:152109

Katoueizadeh E, Zebarjad SM, Janghorban K (2019) Investigating the effect of synthesis conditions on the formation of urea–formaldehyde microcapsules. J Mater Res Technol 8:541–552

Zhou X, Yin L, Yang B, Chen C, Chen W, **e Y, Yang X, Pham JT, Liu S, Xue L (2021) Programmable local orientation of micropores by mold-assisted ice templating. Small Methods 5:2000963

Yang J, Yang W, Chen W, Tao X (2020) An elegant coupling: freeze-casting and versatile polymer composites. Prog Polym Sci 109:101289

Deville S (2019) Wood-like polymeric materials by ice templating. Natl Sci Rev 6:184–185

Papa E, Mor M, Natali Murri A, Landi E, Medri V (2020) Ice-templated geopolymer beads for dye removal. J Colloid Interface Sci 572:364–373

Gupta K, Joshi P, Gusain R, Khatri OP (2021) Recent advances in adsorptive removal of heavy metal and metalloid ions by metal oxide-based nanomaterials. Coordin Chem Rev 445:214100

Zhao J, Liu J, Li N, Wang W, Nan J, Zhao Z, Cui F (2016) Highly efficient removal of bivalent heavy metals from aqueous systems by magnetic porous Fe3O4-MnO2: adsorption behavior and process study. Chem Eng J 304:737–746

Kosa SA, Al-Zhrani G, Abdel Salam M (2012) Removal of heavy metals from aqueous solutions by multi-walled carbon nanotubes modified with 8-hydroxyquinoline. Chem Eng J 181–182:159–168

Hua R, Li Z (2014) Sulfhydryl functionalized hydrogel with magnetism: synthesis, characterization, and adsorption behavior study for heavy metal removal. Chem Eng J 249:189–200

Liu Y, Zhang W, Zhao C, Wang H, Chen J, Yang L, Feng J, Yan W (2019) Study on the synthesis of poly(pyrrole methane)s with the hydroxyl in different substituent position and their selective adsorption for Pb2+. Chem Eng J 361:528–537

Funding

The authors declare that no funding was given for the work and paper.

Author information

Authors and Affiliations

Contributions

TC and HH conceived the idea and designed the experiments. TC and XH carried out the experiments, and GX analyzed the data. TC, RY, and GX co-wrote the manuscript, and all authors participated in data analysis and discussions and read and edited the manuscript. LZ and QW directed the project.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare to have no conflict of interest and paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Cheng, T., Hou, H., Xu, G. et al. Transformation of Urea–Formaldehyde Resin Waste into Pb(II) and Cu(II) Adsorbent Toward a Circular Materials Economy Approach. J Polym Environ 31, 2612–2623 (2023). https://doi.org/10.1007/s10924-022-02755-0

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-022-02755-0