Abstract

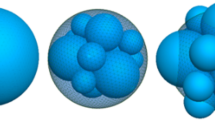

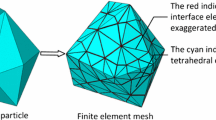

The impact of crushing on the macroscopic mechanical characteristics of granular materials from a microscopic perspective has recently been revealed using the discrete element method (DEM). The influence of the self-organized, mass conservation and volume conservation of daughter particles in the fragment replacement method (FRM) on particle breakage is complex and crucial. In this paper, 14-ball Apollo directly filling method (DFM) and expansion method are combined to keep balance among particles before and after crushing, considered to establish DEM to simulate granular material. By considering the influence of volume loss on the micro-fracture condition of the samples, the macro-responses of mechanical and deformation characteristics, the gradation change and the critical state are studied. The effect of inter-particle interaction on macroscopic properties is also analyzed from the microscopic perspective. The rationality of the volume expansion method is verified. The comparisons of samples with volume conservation and volume loss show that the stress development process and the volumetric strain are affected. The existence of the balance point of volume effect is related to the stress level which lead to the difference in stress and strain. Through analysis of relative breakage index (Br) and the statistical number of microscopic particles, it can be seen that the gradation deviation comes from the two-way influence of the volume loss on the crushing of particles. The volume loss has no effect on stress ratio in the critical state, but has a significant effect on stress change during shearing process, and results in the critical state void ratio to decrease with increasing confining pressure. The rationality of daughter particles’ volume conservation are analyzed from the motion, displacement development and force chain evolution.

Similar content being viewed by others

Data Availability

Some or all data, models, or code that support the findings of this study are available from the corresponding author upon reasonable request

References

**ao Y, Liu H, Ding X, Chen Y, Jiang J, Zhang W (2016) Influence of particle breakage on critical state line of rockfill material. Int J Geomech 16(1):04015031. https://doi.org/10.1061/(ASCE)GM.1943-5622.0000538

Koohmishi M, Palassi M (2017) Effect of particle size distribution and subgrade condition on degradation of railway ballast under impact loads. Granular Matter 19(3):1–12. https://doi.org/10.1007/s10035-017-0747-0

Mark DS, Corinna R, Edmund PG (2001) World Atlas of Coral Reefs. University of California Press, Berkeley

Cundall PA, Strack O (2008) A discrete numerical model for granular assemblies. Géotechnique 30(3):331–336. https://doi.org/10.1680/geot.1979.29.1.47

Coop MR, Sorensen KK, Freitas TB, Georgoutsos G (2004) Particle breakage during shearing of a carbonate sand. Géotechnique 54(3):157–163. https://doi.org/10.1680/geot.2004.54.3.157

Ghafghazi M, Shuttle DA, Dejong JT (2014) Particle breakage and the critical state of sand. Soils Found 54(3):451–461. https://doi.org/10.1016/j.sandf.2014.04.016

Yu F (2017) Characteristics of particle breakage of sand in triaxial shear. Powder Technol 320:656–667. https://doi.org/10.1016/j.powtec.2017.08.001

Thornton C, Ciomocos MT, Adams MJ (1999) Numerical simulations of agglomerate impact breakage. Powder Technol Lausanne 105(1–3):74–82. https://doi.org/10.1016/S0032-5910(99)00120-5

Cheng YP, Nakata Y, Bolton MD (2003) Discrete element simulation of crushable soil. Géotechnique 53(7):633–641. https://doi.org/10.1680/geot.2003.53.7.633

Mcdowell GR, Harireche O (2002) Discrete element modelling of soil particle fracture. Géotechnique 52(2):131–135. https://doi.org/10.1680/geot.2002.52.2.131

Mcdowell GR, Harireche O (2002) Discrete element modelling of yielding and normal compression of sand. Geotechnique 52(4):299–304. https://doi.org/10.1680/geot.2002.52.4.299

Lobo-Guerrero S, Vallejo LE (2005) Crushing a weak granular material: experimental numerical analyses. Géotechnique 55(3):245–249. https://doi.org/10.1680/geot.2005.55.3.245

Marketos G, Bolton MD (2009) Compaction bands simulated in discrete element models. J Struct Geol 31(5):479–490. https://doi.org/10.1016/j.jsg.2009.03.002

Bono JP, Mcdowell GR (2014) DEM of triaxial tests on crushable sand. Granular Matter 16(4):551–562. https://doi.org/10.1007/s10035-014-0500-x

Bono JP, Mcdowell GR (2013) On the micro mechanics of one-dimensional normal compression. Géotechnique 63(11):895–908. https://doi.org/10.1680/geot.12.P.041

Åström MJ, Herrmann HJ (1998) Fragmentation of grains in a two-dimensional packing. Physics of Condensed Matter 570(83):551–554. https://doi.org/10.1007/s100510050476

Ciantia MO, Arroyo M, Calvetti F, Gens A (2015) An approach to enhance efficiency of DEM modelling of soils with crushable grains. Géotechnique 65(2):91–110. https://doi.org/10.1680/geot.13.P.218

Lobo-Guerrero S, Vallejo LE, Vesga LF (2006) Visualization of crushing evolution in granular materials under compression using DEM. Int J Geomech 6(3):195–200. https://doi.org/10.1061/(ASCE)1532-3641(2006)6:3(195)

Ben-Nun O, Einav I (2010) The role of self-organization during confined comminution of granular materials. Philos Trans A Math Phys Eng 368(1910):231–247. https://doi.org/10.1098/rsta.2009.0205

Shi DD, Cao D, Deng Y, Xue J (2020) Dem investigations of the effects of intermediate principal stress ratio and particle breakage on the critical state behaviors of granular soils. Powder Technol 379(3):547–559. https://doi.org/10.1016/j.powtec.2020.10.094

Cleary PW (2001) Recent advances in DEM modelling of tumbling mills. Miner Eng 14(10):1295–1319. https://doi.org/10.1016/S0892-6875(01)00145-5

Cleary PW, Sinnott MD (2015) Simulation of particle flows and breakage in crushers using DEM: Part 1-Compression crushers. Miner Eng 74:178–197. https://doi.org/10.1016/j.mineng.2014.10.021

Li HQ, McDowell G, Lowndes I (2014) Discrete element modelling of a rock cone crusher. Powder Technol 263:151–158. https://doi.org/10.1016/j.powtec.2014.05.004

Yue P, De Bono JP, Yu HS, Mcdowell GR (2013) Micro mechanics of isotropic normal compression. Géotechnique Letters 3(4):166–172. https://doi.org/10.1680/geolett.13.00050

Bono JP, Mcdowell GR (2018) Micro mechanics of drained and undrained shearing of compacted and overconsolidated crushable sand. Géotechnique 68(7):575–589. https://doi.org/10.1680/jgeot.16.P.318

Zhou W, Yang L, Ma G, Chang X, Cheng Y, Li D (2015) Macro–micro responses of crushable granular materials in simulated true triaxial tests. Granular Matter 17(4):497–509. https://doi.org/10.1007/s10035-015-0571-3

Ben-Nun O, Einav I, Tordesillas A (2010) Force attractor in confined comminution of granular materials. Phys Rev Lett 104(10):108001. https://doi.org/10.1103/PhysRevLett.104.108001

Carslaw HS, Jaeger JC (1940) Some Two-Dimensional Problems in Conduction of Heat with Circular Symmetry. Proc Lond Math Soc 46(1):361–388. https://doi.org/10.1112/plms/s2-46.1.361

De Bono J, Mcdowell GR (2016) Particle breakage criteria in discrete-element modelling. Géotechnique 66(12):1014–1027. https://doi.org/10.1680/jgeot.15.P.280

Russell AR, Wood DM (2009) Point load tests and strength measurements for brittle spheres. Int J Rock Mech Min Sci 46(2):272–280. https://doi.org/10.1016/j.ijrmms.2008.04.004

Russell AR, Wood DM, Kikumoto M (2009) Crushing of particles in idealised granular assemblies. J Mech Phys Solids 57(8):1293–1313. https://doi.org/10.1016/j.jmps.2009.04.009

Hiramatsu Y, Oka Y (1966) Determination of the tensile strength of rock by a compression test of an irregular test piece. Int J Rock Mech Min Sci Geomech Abstr 3(2):89–90. https://doi.org/10.1016/0148-9062(66)90002-7

Christensen RM (2000) Yield functions, damage states, and intrinsic strength. Math Mech Solids 5(3):285–300. https://doi.org/10.1177/108128650000500302

Weibull W (1951) A statistical distribution function of wide applicability. Jour App Mech 18:293–297. https://doi.org/10.1115/1.4010337

Mcdowell GR (2002) On the yielding and plastic compression of sand. Soils Found 42(1):139–145. https://doi.org/10.3208/sandf.42.1139

Borkovec M, Paris WD, Peikert R (1994) The fractal dimension of the apollonian sphere packing. Fractals-complex Geom Patterns Scaling Nat Soc 2(04):521–526. https://doi.org/10.1142/S0218348X94000739

Ciantia MO, Arroyo M, O’Sullivan C, Gens A, Liu T (2018) Grading evolution and critical state in a discrete numerical model of Fontainebleau sand. Géotechnique 69(1):1–15. https://doi.org/10.1680/jgeot.17.P.023

Roscoe K, Schofield AN, Wroth CP (1958) On Yielding Soils Géotechn 8(1):22–53. https://doi.org/10.1680/geot.1958.8.1.22

Marsal RJ (1967) Large-scale testing of rockfill materials. J Soil Mech Found Division 93(2):27–43. https://doi.org/10.1061/JSFEAQ.0000958

Lade PV, Yamamuro JA, Bopp PA (1996) Significance of particle crushing in granular materials. J Geotechn Eng 122(4):309–316. https://doi.org/10.1061/(ASCE)0733-9410(1996)122:4(309)

Hardin BO (1985) Crushing of soil particles. J Geotechn Eng 111(10):1177–1192. https://doi.org/10.1061/(ASCE)0733-9410(1985)111:10(1177)

Einav I (2007) Breakage mechanics part I: theory. J Mech Phys Solids 55(6):1274–1297. https://doi.org/10.1016/j.jmps.2006.11.003

Li XS, Dafalias YF (2000) Dilatancy for cohesionless soils Géotechnique 50(4):449–460. https://doi.org/10.1680/geot.2000.50.4.449

Acknowledgements

This study was supported by the National Outstanding Youth Science Fund Project of the National Natural Science Foundation of China (Grant No. 51722801).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

No potential conflict of interest was reported by the authors.

Additional information

Handling Editor: M. Grant Norton.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jiao, S., Xu, C., Xu, J. et al. Influence of volume loss for the fragment replacement method (FRM) in three dimensions. J Mater Sci 58, 3231–3248 (2023). https://doi.org/10.1007/s10853-023-08260-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-023-08260-6