Abstract

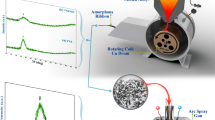

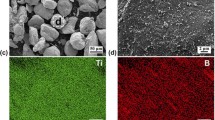

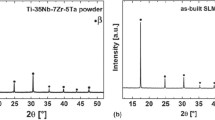

The Ti–15Mo alloy has become a widely recognized biomedical Ti alloy due to its excellent properties, including a low Young’s modulus that is close to that of a human bone. Selective laser melting (SLM) additive manufacturing (AM) offers both advanced manufacturing capabilities to the processing of the alloy and the potential to make customized implants. The feedstock cost of pre-alloyed Ti–15Mo powder, however, is high, like that of many other Ti alloys, and can be a major obstacle to the wider application of the AM technique. This study focused on mitigating this problem by using an in situ laser alloying approach, wherein a low-cost hydride-dehydrate (HDH) Ti powder was mechanically mixed with elemental Mo powder to form a composite powder feedstock (i.e., Ti + Mo). The Ti–15Mo alloy could be printed with a high relative density (~ 99.76%). A finite element simulation was performed to study the melt pool during the SLM process with subsequent detailed discussions to understand the in situ alloying mechanism. Mechanical property indicates the as-printed Ti–15Mo has high strength (~ 1170 MPa) but low ductility, while the latter has been much improved by introducing a merely 0.2 wt% of yttrium (Y). Based on the optimized Ti–15Mo–0.2Y alloy with a strength of ~ 1300 MPa and a modulus of ~ 85 GPa, different amounts of elemental Ag powder were further alloyed in situ to acquire antibacterial properties. Compared with the antibacterial activity of the control group, that of the final material, i.e., in situ laser alloyed Ti–15Mo–0.2Y–2.5Ag, reached 92–95%; the addition of Ag had a minimal effect on the cell viability. In vivo experiments demonstrated the Ag-containing alloys to exhibit good biocompatibility.

Graphical Abstract

Similar content being viewed by others

References

Xu J, Zhang J, Shi Y, Tang J, Huang D, Yan M, Dargusch MS (2022) Surface Modification of biomedical Ti and Ti Alloys: a review on current advances. Materials 15(5):1749. https://doi.org/10.3390/ma15051749

A International (2017) Standard Specification for Unalloyed Titanium, for Surgical Implant Applications (UNS R50250, UNS R50400, UNS R50550, UNS R50700). https://doi.org/10.1520/F0067-13R17

Kolli RP, Arun D (2018) A review of metastable beta titanium alloys. Metals 8(7):506. https://doi.org/10.3390/met8070506

A International (2018) Standard Specification for Wrought Titanium-15 Molybdenum Alloy for Surgical Implant Applications (UNS R58150). https://doi.org/10.1520/F2066_F2066M-13

Yan M, Qian M, Kong C, Dargusch MS (2014) Impacts of trace carbon on the microstructure of as-sintered biomedical Ti–15Mo alloy and reassessment of the maximum carbon limit. Acta Biomater 10(2):1014–1023

Geetha M, Singh AK, Asokamani R, Gogia AK (2009) Ti based biomaterials, the ultimate choice for orthopaedic implants-a review. Prog Mater Sci 54(3):397–425

dos Santos ML, Riccardi CD, de Almeida E, Guastaldi AC (2018) Calcium phosphates of biological importance based coatings deposited on Ti–15Mo alloy modified by laser beam irradiation for dental and orthopedic applications. Ceram Int 44(18):22432–22438

Liu G, Yang Y, Luo X, Huang B, Li P (2017) The phase, morphology and surface characterization of Ti–Mo alloy films prepared by magnetron sputtering. RSC Adv 7(83):52595–52603

Alshammari Y, Yang F, Bolzoni L (2019) Low-cost powder metallurgy Ti–Cu alloys as a potential antibacterial material. J Mech Behav Biomed Mater 95:232–239

Fowler L, Masia N, Cornish LA, Chown LH, Engqvist H, Norgren S, Öhman-Mägi C (2019) Development of antibacterial Ti–Cux alloys for dental applications: effects of ageing for alloys with up to 10 wt% Cu. Materials 12(23):4017. https://doi.org/10.3390/ma12234017

Shi A, Zhu C, Fu S, Wang R, Qin G, Chen D, Zhang E (2020) What controls the antibacterial activity of Ti–Ag alloy, Ag ion or Ti2Ag particles? Mater Sci Eng C 109:110548. https://doi.org/10.1016/j.msec.2019.110548

Lei Z, Zhang H, Zhang E, You J, Ma X, Bai X (2018) Antibacterial activities and biocompatibilities of Ti–Ag alloys prepared by spark plasma sintering and acid etching. Mater Sci Eng C-Mater Biol Appl 92:121–131

Zhang XY, Wang HZ, Li JF, He XJ, Hang RQ, Huang XB, Tian LH, Tang B (2016) Corrosion behavior of Zn-incorporated antibacterial TiO2 porous coating on titanium. Ceram Int 42(15):17095–17100

Li Q, Li L, Zhao M, Dong L, Wu J, Li D (2019) Biological actions of Cu/Zn coimplanted TiN on Ti–6Al–4V alloy. Biointerphases 14(5):051008. https://doi.org/10.1116/1.5116640

McDonnell G, Russell AD (1999) Antiseptics and disinfectants: activity, action, and resistance. Clin Microbiol Rev 12(1):147–179

Lei Z, Zhang H, Zhang E, You J, Ma X, Bai X (2020) Antibacterial activities and cell responses of Ti–Ag alloys with a hybrid micro- to nanostructured surface. J Biomater Appl 34(10):1368–1380

Zhang E, Liu C (2015) Effect of surface treatments on the surface morphology, corrosion property, and antibacterial property of Ti–10Cu sintered alloy. Biomed Mater 10(4):045009. https://doi.org/10.1088/1748-6041/10/4/045009

Ning C, Wang X, Li L, Zhu Y, Li M, Yu P, Zhou L, Zhou Z, Chen J, Tan G, Zhang Y, Wang Y, Mao C (2015) Concentration ranges of antibacterial cations for showing the highest antibacterial efficacy but the least cytotoxicity against mammalian cells: implications for a new antibacterial mechanism. Chem Res Toxicol 28(9):1815–1822

Zhou YH, Li WP, Wang DW, Zhang L, Ohara K, Shen J, Ebel T, Yan M (2019) Selective laser melting enabled additive manufacturing of Ti–22Al–25Nb intermetallic: excellent combination of strength and ductility, and unique microstructural features associated. Acta Mater 173:117–129

Zhou YH, Lin SF, Hou YH, Wang DW, Zhou P, Han PL, Li YL, Yan M (2018) Layered surface structure of gas-atomized high Nb-containing TiAl powder and its impact on laser energy absorption for selective laser melting. Appl Surf Sci 441:210–217

Guo S, Lu Y, Wu S, Liu L, He M, Zhao C, Gan Y, Lin J, Luo J, Xu X, Lin J (2017) Preliminary study on the corrosion resistance, antibacterial activity and cytotoxicity of selective-laser-melted Ti6Al4V–xCu alloys. Mater Sci Eng C-Mater Biol Appl 72:631–640

Zhang BB, Wang BL, Wang YB, Li L, Zheng YF, Liu Y (2012) Development of Ti–Ag–Fe ternary titanium alloy for dental application. J Biomed Mater Res Part B 100B(1):185–196

Maharubin S, Hu Y, Sooriyaarachchi D, Cong W, Tan GZ (2019) Laser engineered net sha** of antimicrobial and biocompatible titanium-silver alloys. Mater Sci Eng C 105:110059. https://doi.org/10.1016/j.msec.2019.110059

Zhang J-M, Zhao Z-Y, Chen Q-H, Chen X-H, Li Y-H (2021) Study of Ag precipitation and mechanical properties of Ti–Ta–Ag ternary alloy. RSC Adv 11(5):2976–2984

Dong YP, Li YL, Zhou SY, Zhou YH, Dargusch MS, Peng HX, Yan M (2021) Cost-affordable Ti–6Al–4V for additive manufacturing: powder modification, compositional modulation and laser in-situ alloying. Addit Manuf 37:101699. https://doi.org/10.1016/j.addma.2020.101699

Mosallanejad MH, Niroumand B, Aversa A, Saboori A (2021) In-situ alloying in laser-based additive manufacturing processes: A critical review. J Alloys Compd 872:159567. https://doi.org/10.1016/j.jallcom.2021.159567

Chen P, Li S, Zhou Y, Yan M, Attallah MM (2020) Fabricating CoCrFeMnNi high entropy alloy via selective laser melting in-situ alloying. J Mater Sci Technol 43:40–43

Sing SL, Huang S, Goh GD, Goh GL, Tey CF, Tan JHK, Yeong WY (2021) Emerging metallic systems for additive manufacturing: in-situ alloying and multi-metal processing in laser powder bed fusion. Prog Mater Sci 119:100795. https://doi.org/10.1016/j.pmatsci.2021.100795

Hou Y, Liu B, Liu Y, Zhou Y, Song T, Zhou Q, Yan M (2019) Ultra-low cost Ti powder for selective laser melting additive manufacturing and superior mechanical properties associated. Opto-Electron Adv 2(5):180028–180031

Dong YP, Tang JC, Wang DW, Wang N, He ZD, Li J, Yan M (2020) Additive manufacturing of pure Ti with superior mechanical performance, low cost, and biocompatibility for potential replacement of Ti–6Al–4V. Mater Des 196:109142. https://doi.org/10.1016/j.matdes.2020.109142

Min X, Bai P, Emura S, Ji X, Cheng C, Jiang B, Tsuchiya K (2017) Effect of oxygen content on deformation mode and corrosion behavior in beta-type Ti-Mo alloy. Mater Sci Eng A-Struct Mater Prop Microstruct Process 684:534–541

Hammond CR (2005) Properties of the Elements and Inorganic Compounds. In: C.R. Hammond (ed.), CRC Handbook of Chemistry and Physics, CRC Press2005 p. 41–42

Xu P, Pyczak F, Yan M, Kong F, Ebel T (2020) Impacts of yttrium on microstructure and tensile properties of biomedical β Ti–Nb–Zr fabricated by metal injection molding. Mater Sci Eng A 792:139816. https://doi.org/10.1016/j.msea.2020.139816

Li WP, Wang H, Zhou YH, Zhu YY, Lin SF, Yan M, Wang N (2022) Yttrium for the selective laser melting of Ti–45Al–8Nb intermetallic: powder surface structure, laser absorptivity, and printability. J Alloys Compd 892:161970. https://doi.org/10.1016/j.jallcom.2021.161970

Dong Y, Li Y, Ebel T, Yan M (2020) Cost-affordable, high-performance Ti–TiB composite for selective laser melting additive manufacturing. J Mater Res 35(15):1922–1935

Wang DW, Zhou YH, Yao XY, Dong YP, Feng SH, Liu ZY, Yan M (2022) Inheritance of microstructure and mechanical properties in laser powder bed fusion additive manufacturing: a feedstock perspective. Mater Sci Eng A 832:142311. https://doi.org/10.1016/j.msea.2021.142311

Iizuka A, Ouchi T, Okabe TH (2020) Ultimate deoxidation method of titanium utilizing Y/YOCl/YCl3 equilibrium, metallurgical and materials transactions b-process metallurgy and materials processing. Science 51(2):433–442

Jiao L-N, Feng Q-S, He S-Y, Duan B-H, Dou Z-H, Li C-H, Lu X-G (2022) Direct oxygen removal from titanium aluminide scraps by yttrium reduction. Trans Nonferrous Met Soc China 32(7):2428–2437

Tang JC, Luo JP, Huang YJ, Sun JF, Zhu ZY, Xu JY, Dargusch MS, Yan M (2020) Immunological response triggered by metallic 3D printing powders. Addit Manuf 35:101392. https://doi.org/10.1016/j.addma.2020.101392

Luo JP, Huang YJ, Xu JY, Sun JF, Dargusch MS, Hou CH, Ren L, Wang RZ, Ebel T, Yan M (2020) Additively manufactured biomedical Ti–Nb–Ta–Zr lattices with tunable Young’s modulus: mechanical property, biocompatibility, and proteomics analysis. Mater Sci Eng, C 114:110903. https://doi.org/10.1016/j.msec.2020.110903

Kokubo T, Takadama H (2006) How useful is SBF in predicting in vivo bone bioactivity? Biomaterials 27(15):2907–2915

Liu S, Shin YC (2019) Additive manufacturing of Ti6Al4V alloy: a review. Mater Des 164:107552. https://doi.org/10.1016/j.matdes.2018.107552

Persson K (2016) Materials Data on Ti (SG:194) by Materials Project. https://doi.org/10.17188/1208281. Accessed 1 May 2022

Wang D, Han H, Sa B, Li K, Yan J, Zhang J, Yan M (2022) review and a statistical analysis of porosity in metals additively manufactured by laser powder bed fusion. Opto-Electron Adv 5(10):210058–210061

Ho WF (2008) A comparison of tensile properties and corrosion behavior of cast Ti–7.5Mo with c.p. Ti, Ti–15Mo and Ti–6Al–4V alloys. J Alloys Compd 464:580–583

Niinomi M (1998) Mechanical properties of biomedical titanium alloys. Mater Sci Eng, A 243(1):231–236

Yadroitsev I, Krakhmalev P, Yadroitsava I (2017) Titanium alloys manufactured by in situ alloying during laser powder bed fusion. Jom 69(12):2725–2730

Sugano M, Tsuchida Y, Satake T, Ikeda M (1998) A microstructural study of fatigue fracture in titanium-molybdenum alloys. Mater Sci Eng A-Struct Mater Prop Microstruct Process 243(1–2):163–168

Martins Júnior JRS, Nogueira RA, Araújo ROD, Donato TAG, Arana-Chavez VE, Claro APRA, Grandini CR (2011) Preparation and characterization of Ti–15Mo alloy used as biomaterial. Mater Res 14:107–112

Mieczyslaw Jurczyk KJ (2012) Biomaterials. In: Jurczyk M (ed) Bionanomaterials for dental applications. Jenny Stanford Publishing, New York. https://doi.org/10.1201/b13255

Duan FH, Lin Y, Pan J, Wang YX, Yao JH, Li Y (2018) Influence of oxygen on the glass formation of Mo–O binary alloys. J Non-Cryst Solids 500:210–216

Ma X, Chen Z, Zhong D, Luo SN, **ao L, Lu W, Zhang S (2021) Effect of rotationally accelerated shot peening on the microstructure and mechanical behavior of a metastable beta titanium alloy. J Mater Sci Technol 75:27–38

Folaranmi G, Tauk M, Bechelany M, Sistat P, Cretin M, Zaviska F (2021) Synthesis and characterization of activated carbon co-mixed electrospun titanium oxide nanofibers as flow electrode in capacitive deionization. Materials 14(22):6891. https://doi.org/10.3390/ma14226891

Lee JC, Gopalan AI, Saianand G, Lee KP, Kim WJ (2020) Manganese and graphene included titanium dioxide composite nanowires: fabrication, characterization and enhanced photocatalytic activities. Nanomaterials 10(3):456. https://doi.org/10.3390/nano10030456

Al-Murshdy JMS, Al-Deen HHJ, Hussein SR (2021) Investigation of the effect of indium addition on the mechanical and electrochemical properties of the Ti–15Mo biomedical alloy. J Bio-Tribo-Corros 7(4):148. https://doi.org/10.1007/s40735-021-00581-w

Yetim T (2016) Corrosion behavior of Ag-doped TiO2 coatings on commercially pure titanium in simulated body fluid solution. J Bionic Eng 13(3):397–405

Venkateswarlu K, Suresh S, Rameshbabu N, Sreekanth D, Sandhyarani M (2013) Role of electric pulse duty and frequency on properties of micro-arc oxidized titania films developed on Ti–6Al–4V. Light Met Technol 2013(765):688–692

Yadroitsev I, Gusarov A, Yadroitsava I, Smurov I (2010) Single track formation in selective laser melting of metal powders. J Mater Process Tech 210(12):1624–1631

Matsui G, Kato H (2011) Analysis of thermal diffusivity of Ti thin film by thermoreflectance and periodic heating technique. Rev Sci Inst 82(3):034905. https://doi.org/10.1063/1.3557389

Edge E (2022) Thermal Diffusivity Table. https://www.engineersedge.com/heat_transfer/thermal_diffusivity_table_13953.htm. Accessed 14 Aug 2022

Technologies A (2014) Microsoft Word - ati_15Mo_Titanium_Alloy_en_v4 final https://www.atimaterials.com/Products/Documents/datasheets/titanium/alloyed/ati_15Mo_Titanium_Alloy_en_v4%20final.pdf. Accessed 8 Mar 2022

MakeItFrom (2018) UNS R58150 Titanium (Ti–15Mo): makeitfrom.com. https://www.makeitfrom.com/material-properties/UNS-R58150-Titanium-Ti-15Mo. Accessed 14 Aug 2022

Wang L, Wang H, Liu Y, Fu Z, Peng T, Shen J, Dai Y (2019) Selective laser melting helps fabricate record-large bulk metallic glass: experiments, simulation and demonstrative part. J Alloys Compd 808:151731. https://doi.org/10.1016/j.jallcom.2019.151731

Lynch DW, Hunter WR (1997) Comments on the optical constants of metals and an introduction to the data for several metals. In: Palik ED (ed) Handbook of optical constants of solids. Academic Press, Burlington, pp 275–367

Lynch DW, Hunter WR (1997) Introduction to the data for several metals. In: Palik ED (ed) Handbook of optical constants of solids. Academic Press, Burlington, pp 233–286

Tang M, Pistorius PC, Beuth JL (2017) Prediction of lack-of-fusion porosity for powder bed fusion. Addit Manuf 14:39–48

Ye J, Khairallah SA, Rubenchik AM, Crumb MF, Guss G, Belak J, Matthews MJ (2019) Energy coupling mechanisms and scaling behavior associated with laser powder bed fusion additive manufacturing. Adv Eng Mater 21(7):1900185. https://doi.org/10.1002/adem.201900185

Dilip JJS, Zhang S, Teng C, Zeng K, Robinson C, Pal D, Stucker B (2017) Influence of processing parameters on the evolution of melt pool, porosity, and microstructures in Ti–6Al–4V alloy parts fabricated by selective laser melting. Prog Addit Manuf 2(3):157–167

Yang J, Han J, Yu H, Yin J, Gao M, Wang Z, Zeng X (2016) Role of molten pool mode on formability, microstructure and mechanical properties of selective laser melted Ti–6A1–4V alloy. Mater Des 110:558–570

Gu RN, Chen P, Zhou YH, Wang H, Yan XC, Wong KS, Yan M (2021) Intentional oxidation and laser remelting of highly reflective pure cu for its high‐quality additive manufacturing. Adv Eng Mater. https://doi.org/10.1002/adem.202101138

Liu J, Wen P (2022) Metal vaporization and its influence during laser powder bed fusion process. Mater Des 215:110505. https://doi.org/10.1016/j.matdes.2022.110505

Cui S, Liu S, Nie J, Chen D, Wu X, Qin G, Zhang E (2022) Design and preparation of a biomedical titanium alloy with low elastic modulus and high antibacterial property based on Ti–Mo–Ag system. J Alloy Compd 908:164639. https://doi.org/10.1016/j.jallcom.2022.164639

Cai D, Zhao X, Yang L, Wang R, Qin G, Chen D-F, Zhang E (2021) A novel biomedical titanium alloy with high antibacterial property and low elastic modulus. J Mater Sci Technol 81:13–25

Chen M, Yang L, Zhang L, Han Y, Lu Z, Qin G, Zhang E (2017) Effect of nano/micro-Ag compound particles on the bio-corrosion, antibacterial properties and cell biocompatibility of Ti–Ag alloys. Mater Sci Eng C-Mater Biol Appl 75:906–917

Lu M, Zhang Z, Zhang J, Wang X, Qin G, Zhang E (2021) Enhanced antibacterial activity of Ti–Cu alloy by selective acid etching. Surf Coat Technol 421:127478. https://doi.org/10.1016/j.surfcoat.2021.127478

Chang YH, Chao CY, Chang YT, Du JK (2020) Effect of phase distribution on the antibacterial property and cytotoxicity of Ti–5Al–2.5 Cu alloy after heat treatment at various temperatures. Metals 10(7):858. https://doi.org/10.3390/met10070858

Sedelnikova MB, Komarova EG, Sharkeev YP, Ugodchikova AV, Mushtovatova LS, Karpova MR, Sheikin VV, Litvinova LS, Khlusov IA (2019) Zn–, Cu– or Ag–incorporated micro-arc coatings on titanium alloys: properties and behavior in synthetic biological media. Surf Coat Technol 369:52–68

Wang R, Tang Y, Li S, Ai Y, Li Y, **ao B, Bai S (2020) Effect of lattice distortion on the diffusion behavior of high-entropy alloys. J Alloys Compd 825:154099. https://doi.org/10.1016/j.jallcom.2020.154099

Roy A, Sreeramagiri P, Babuska T, Krick B, Ray PK, Balasubramanian G (2021) Lattice distortion as an estimator of solid solution strengthening in high-entropy alloys. Mater Charact 172:110877. https://doi.org/10.1016/j.matchar.2021.110877

Xu J, Ding Y, Gao Y, Wang H, Hu Y, Zhang D (2021) Grain refinement and crack inhibition of hard-to-weld Inconel 738 alloy by altering the scanning strategy during selective laser melting. Mater Des 209:109940. https://doi.org/10.1016/j.matdes.2021.109940

**ong W, Hao L, Peijs T, Yan C, Cheng K, Gong P, Li Y (2022) Simultaneous strength and ductility enhancements of high thermal conductive Ag7.5Cu alloy by selective laser melting. Sci Rep 12(1):1–15

Acknowledgements

The project was supported by State Key Laboratory of Materials Processing and Die & Mould Technology, Huazhong University of Science and Technology [No. P2021-013], Guangdong Basic and Applied Basic Research Foundation [2020B1515120013], and National Natural Science Foundation of China [Nos. 51971108 and 52271032]. Dr. Ming Yan appreciates the support of the Humboldt Research Fellowship for Experienced Researchers.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Handling Editor: Annela M. Seddon.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

J. Y. Xu and K. L. Li are co-first-authors.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Xu, J.Y., Li, K.L., Tang, J.C. et al. Additive manufacturing of anti-bacterial and low-cost Ti–Mo(–Ag) alloys using elemental powders through in situ laser alloying. J Mater Sci 58, 2268–2293 (2023). https://doi.org/10.1007/s10853-022-08107-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-022-08107-6