Abstract

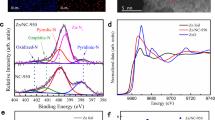

The development of economic catalysts for aerobic oxidation procedure has attracted extensive attention. In this work, a novel Ni/Zn supported defective carbon with multi-functional catalytic sites was fabricated via a two-step pyrolysis-H2O2 treatment. The catalyst was applied to the Baeyer–Villiger (B–V) oxidation using ambient air as a green and safe oxidant. The catalyst with optimal Ni/Zn ratio of (2:1) delivers a high catalytic activity (> 92%) and perfect selectivity (> 99%) for the conversion of a wide range of substituted cyclic-ketones to the corresponding lactones. The characterization results have clarified that the H2O2 treatment leads to the formation of active N/O-group on the catalyst surface, which facilitates the adsorption of substrate/intermediate molecules and benefits the reaction. Moreover, the synergistic effect between multi-functional sites results in the buffering/stabilizing of free radicals, enhanced efficiency of oxygen insertion to form lactone. The design principle in this work is believed to shed light on the exploration of all-in-one solid catalyst for diverse oxidative reaction.

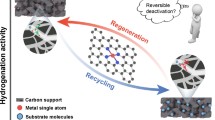

Graphical Abstract

Similar content being viewed by others

References

Chamas A, Moon H, Zheng J et al (2020) ACS Sus Chem Engin 8:3494. https://doi.org/10.1021/acssuschemeng.9b06635

Wei R, Tiso T, Bertling J, O’Connor K, Blank LM, Bornscheuer UT (2020) Nat Catal 3:867. https://doi.org/10.1038/s41929-020-00521-w

Meereboer KW, Misra M, Mohanty AK (2020) Green Chem 22:5519. https://doi.org/10.1039/d0gc01647k

Filiciotto L, Rothenberg G (2021) Chemsuschem 14:56. https://doi.org/10.1002/cssc.202002044

Uyanik M, Ishihara K (2013) ACS Catal 3:513. https://doi.org/10.1021/cs300821u

Baeyer A, Villiger V (1899) Ber Dtsch Chem Ges 32:3625. https://doi.org/10.1002/cber.189903203151

Renz M, Meunier B (1999) Eur J Organ Chem 1999:737. https://doi.org/10.1002/(SICI)1099-0690(199904)1999

Brink GJ, Arends I, Sheldon RA (2004) Chem Rev 104:4105. https://doi.org/10.1021/cr030011l

Liu C, Wen KG, Zeng XP, Peng YY (2020) Adv Syn Catal 362:1015. https://doi.org/10.1002/adsc.201901178

Fürst MJLJ, Gran-Scheuch A, Aalbers FS, Fraaije MW (2019) ACS Catal 2019:11207. https://doi.org/10.1021/acscatal.9b03396

Markiton M, Boncel S, Janas D, Chrobok A (2016) ACS Sus Chem Engin 5:1685. https://doi.org/10.1021/acssuschemeng.6b02433

Leisch H, Morley K, Lau PC (2011) Chem Rev 111:4165. https://doi.org/10.1021/cr1003437

Jeong E-Y, Ansari MB, Park S-E (2011) ACS Catal 1:855. https://doi.org/10.1021/cs200163r

Chen S, Zhou X, Li Y, Luo R, Ji H (2014) Chem Engin J 241:138. https://doi.org/10.1016/j.cej.2013.12.027

Rahman S, Enjamuri N, Gomes R et al (2015) Appl Catal A: Gen 505:515. https://doi.org/10.1016/j.apcata.2015.03.014

Tang Z, **ao J, Li F et al (2020) ACS Omega 5:10451. https://doi.org/10.1021/acsomega.0c00443

**ao H, Shin H, Goddard WA 3rd (2018) Proc Natl Acad Sci USA 115:5872. https://doi.org/10.1073/pnas.1722034115

** Y, Huang S, Yue X, Du H, Shen PK (2018) ACS Catal 8:2359. https://doi.org/10.1021/acscatal.7b04226

Zheng C, Chang S, Yang C et al (2018) Tetrahedron 74:2608. https://doi.org/10.1016/j.tet.2018.04.009

Huo H, Wu L, Ma J et al (2016) ChemCatChem 8:779. https://doi.org/10.1002/cctc.201501107

Liu Z, Zhou Z, Qin J, Liu G, Huang H, Wu W (2018) ChemistrySelect 3:6434. https://doi.org/10.1002/slct.201801247

Zhou Z, Wang J, Qin J, Yu Y, Wu W (2017) J Porous Mater 25:835. https://doi.org/10.1007/s10934-017-0496-9

Li Y-F, Guo M-Q, Yin S-F et al (2013) Carbon 55:269. https://doi.org/10.1016/j.carbon.2012.12.036

Nabae Y, Rokubuichi H, Mikuni M, Kuang Y, Hayakawa T, Kakimoto M-a (2013) Catalysis by carbon materials for the aerobic baeyer-villiger oxidation in the presence of aldehydes. ACS Catal 3(2):230–236

Chen S-Y, Zhou X-T, Wang J-X et al (2017) Mol Catal 438:152. https://doi.org/10.1016/j.mcat.2017.06.001

Wei Z, Wang J, Mao S et al (2015) ACS Catal 5:4783. https://doi.org/10.1021/acscatal.5b00737

Hu M, Reboul J, Furukawa S et al (2012) J Am Chem Soc 134:2864. https://doi.org/10.1021/ja208940u

Zhong G, Li S, Xu S, Liao W, Fu X, Peng F (2018) ACS Sus Chem Engin 6:15108. https://doi.org/10.1021/acssuschemeng.8b03582

Wang Y, Liu Y, Liu W, Chen H, Zhang G, Wang J (2015) Mater Lett 154:64. https://doi.org/10.1016/j.matlet.2015.04.073

Wang X, Blechert S, Antonietti M (2012) ACS Catal 2:1596. https://doi.org/10.1021/cs300240x

Zhang M, Gao B (2013) Chem Engin J 226:286. https://doi.org/10.1016/j.cej.2013.04.077

Peng Y, Liu HW (2006) Ind Engin Chem Res 45:6483. https://doi.org/10.1021/ie0604627

Donoeva B, Masoud N, de Jongh PE (2017) ACS Catal 7:4581. https://doi.org/10.1021/acscatal.7b00829

Yang X, Wan Y, Zheng Y et al (2019) Chem Engin J 366:608. https://doi.org/10.1016/j.cej.2019.02.119

**a J, He G, Zhang L, Sun X, Wang X (2016) Appl Catal B: Environ 180:408. https://doi.org/10.1016/j.apcatb.2015.06.043

Wang Y, Ren N, ** J et al (2021) ACS ES&T Engin 1:32. https://doi.org/10.1021/acsestengg.0c00004

Zhang X, Yang H, Yang G, Li S, Wang X, Ma J (2018) ACS Sus Chem & Engin 6:5868. https://doi.org/10.1021/acssuschemeng.7b04167

Sun M, Liu H-H, Tao X-F, Zhai L-F, Wang S (2021) ACS ES&T Engin 1:173. https://doi.org/10.1021/acsestengg.0c00036

Li J, Shen B, Hong Z, Lin B, Gao B, Chen Y (2012) Chem Comm 48:12017. https://doi.org/10.1039/C2CC35862J

Wan X, Zhou C, Chen J et al (2014) ACS Catal 4:2175. https://doi.org/10.1021/cs5003096

He L, Weniger F, Neumann H, Beller M (2016) Angew Chem Int Ed 55:12582. https://doi.org/10.1002/anie.201603198

Cao Y, Mao S, Li M, Chen Y, Wang Y (2017) ACS Catal 7:8090. https://doi.org/10.1021/acscatal.7b02335

Deng H, Li Q, Liu J, Wang F (2017) Carbon 112:219. https://doi.org/10.1016/j.carbon.2016.11.014

Acknowledgements

This work is supported by the National Natural Science Foundation of China (No. 21773195). Y.S. Sun also thanks the financial support from Guangdong Basic and Applied Basic Research Foundation (2020A1515110904), State Key Laboratory of Physical Chemistry of Solid Surfaces, **amen University and Nanqiang Young Top-notch Talent Fellowship from **amen University.

Author information

Authors and Affiliations

Contributions

The manuscript was written through contributions of all authors. All authors have given approval to the final version of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing financial interest.

Additional information

Handling Editor: Joshua Tong.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Ma, X., Li, B., Shi, K. et al. Ni-Zn supported defective carbon with multi-functional catalytic sites for Baeyer–Villiger reaction using air as oxidant. J Mater Sci 56, 14684–14699 (2021). https://doi.org/10.1007/s10853-021-06197-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-021-06197-2