Abstract

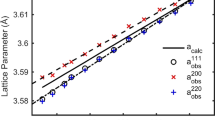

In the present study, X-ray diffraction was applied to measure stacking fault energy of Cr–Ni austenitic steels containing different amounts of alloying elements. The results in austenitic steels show that the Ni content and Cr/Ni ratio have a strong effect on SFE. Cu, Si and N increase SFE, being the effect of nitrogen more pronounced; Mo has the opposite effect. In situ XRD experiments up to 300 °C were employed to determine experimentally the SFE and its temperature dependence in Ni and AISI 304. The microstructural parameters required to determine SFE, obtained by Rietveld refinement, made possible to determine experimentally an increase in the SFE with the temperature, related to a decrease in the accumulated deformation, a lower tendency to form stacking faults and a thermal expansion as the temperature increases. The accuracy was determined based on SFE measurements of Au, Cu and Ni pure metals, where the error of the applied method was carefully evaluated.

Similar content being viewed by others

Data availability

The raw/processed data required to reproduce these findings cannot be shared at this time as the data also forms part of an ongoing study.

References

Saeed-Akbari A, Schwedt A, Bleck W (2012) Low stacking fault energy steels in the context of manganese-rich iron-based alloys. Script Mater 66(12):1024–1029. https://doi.org/10.1016/j.scriptamat.2011.12.041

Lu J, Hultman L, Holmström E, Antonsson KH, Grehk M, Wei L, Vitos L, Golpayegani A (2016) Stacking fault energies in austenitic stainless steels. Acta Mater 111:39–46. https://doi.org/10.1016/j.actamat.2016.03.042

Su J, Raabe D, Li Z (2019) Hierarchical microstructure design to tune the mechanical behavior of an interstitial TRIP-TWIP high-entropy alloy. Acta Mater 163:40–54. https://doi.org/10.1016/j.actamat.2018.10.017

Curtze S, Kuokkala V-T (2010) Dependence of tensile deformation behavior of TWIP steels on stacking fault energy, temperature and strain rate. Acta Mater 58(15):5129–5141. https://doi.org/10.1016/j.actamat.2010.05.049

Wei D, Li X, Jiang J, Heng W, Koizumi Y, Choi W-M, Lee B-J, Kim HS, Kato H, Chiba A (2019) Novel Co-rich high performance twinning-induced plasticity (TWIP) and transformation-induced plasticity (TRIP) high-entropy alloys. Script Mater 165:39–43. https://doi.org/10.1016/j.scriptamat.2019.02.018

Berns H, Gavriljuk V, Riedner S (2013) High interstitial stainless austenitic steels. Springer, Berlin, Heidelberg

Jimenez JA, Frommeyer G (2010) Analysis of the microstructure evolution during tensile testing at room temperature of high-manganese austenitic steel. Mater Charact 61(2):221–226. https://doi.org/10.1016/j.matchar.2009.11.013

Sato K, Ichinose M, Hirotsu Y, Inoue Y (1989) Effects of deformation induced phase transformation and twinning on the mechanical properties of austenitic Fe—Mn–Al Alloys. ISIJ Int 29:868–877

Grässel O, Kruger L, Frommeyer G, Meyer LW (2000) High strength Fe–Mn–(Al, Si) TRIP/TWIP steels development, properties, application. Int J Plast 16:1391–409

Kocks UF, Mecking H (2003) Physics and phenomenology of strain hardening: the FCC case. Progr Mater Sci 48:171–273

Berns H, Fischer A, Kleff J (1993) Scratch tests on iron-, nickel- and cobalt-based alloys at elevated temperatures. Wear 162–164:585–589

Petrov Y (2005) On the electron structure of Mn-, Ni- and Cr–Ni–Mn austenite with different stacking fault energy. Script Mater 10:1201–1206. https://doi.org/10.1016/j.scriptamat.2005.07.002

Das A (2016) Revisiting stacking fault energy of steels. Metall Mat Trans A 47(2):748–768. https://doi.org/10.1007/s11661-015-3266-9

Curtze S, Kuokkala V-T, Oikari A, Talonen J, Hänninen H (2011) Thermodynamic modeling of the stacking fault energy of austenitic steels. Acta Mater 3:1068–1076. https://doi.org/10.1016/j.actamat.2010.10.037

Miodownik AP (1978) The calculation of stacking-fault energies in Fe–Ni–Cr alloys. Calphad 3:207–226

Ferreira PJ, Müllner P (1998) A thermodynamic model for the stacking-fault energy. Acta Mater 46:4479–4484

Molnár D, Engberg G, Li W, Vitos L (2018) Deformation properties of austenitic stainless steels with different stacking fault energies. MSF 941:190–197. https://doi.org/10.4028/www.scientific.net/MSF.941.190

Schramm RE, Reed RP (1975) Stacking fault energies of seven commercial austenitic stainless steels. Metall Mater Trans A 6A:1345–1351

Stobbs WM, Sworn CH (1971) The weak beam technique as applied to the determination of the stacking-fault energy of copper. Philos Mag 24(192):1365–1381. https://doi.org/10.1080/14786437108217418

Reed RP (1974) Relationship between stacking-fault energy and x-ray measurements of stacking-fault probability and microstrain. J Appl Phys 45(11):4705–4728. https://doi.org/10.1063/1.1663122

Bampton CC, Jones IP, Loretto MH (1978) Stacking fault energy measurements in some austenitic stainless steels. Acta Metall 26:39–51. https://doi.org/10.1016/0001-6160(78)90200-6

Rietveld HM (1969) A profile refinement method for nuclear and magnetic structures. J Appl Crystallogr 2:65–71

Grazulis S, Chateigner D, Downs RT, Yokochi AFT, Quirós M, Lutterotti L, Manakova E, Butkus J, Moeck P, Le Bail A (2009) Crystallography open database—an open-access collection of crystal structures. J Appl Crystallogr 42(4):726–729. https://doi.org/10.1107/S0021889809016690

Spiess L, Teichert G, Schwarzer R, Behnken H, Genzel C (2009) Moderne Röntgenbeugung. Vieweg+Teubner Verlag, Wiesbaden

McCusker LB, von Dreele RB, Cox DE, Louerd D, Scard P (1999) Rietveld refinement guidelines. J Appl Cryst 32:36–50

Young RA (ed) (2002) The Rietveld method, Repr. Oxford science publications, vol 5. Oxford Univ. Press, Oxford

Lutterotti L, Matthies S, Wenk H-R (1999) MAUD: a friendly Java program for material analysis using diffraction. IUCr Lett 21:14–15

Mittemeijer EJ, Scardi P (2011) Diffraction analysis of the microstructure of materials. Springer series in materials science. Springer, Berlin

Fanninger G, Hartmann U, Schaler W (1975) Gezielte Untersuchungen zur quantitativen röntgenographischen Phasenanalyse. HTM 30:231–237

Tritt TM (2004) Thermal conductivity: theory, properties, and applications. Physics of solids and liquids. Kluwer Academic/Plenum Publishers, Boston, MA

Gottstein G (2007) Physikalische Grundlagen der Materialkunde. Springer, Berlin

Popa NC (1998) The (hkl) dependence of diffraction-line broadening caused by strain and size for all laue groups in rietveld refinement. J Appl Cryst 31:176–180

Kisko A, Misra R, Talonen J, Karjalainen LP (2013) The influence of grain size on the strain-induced martensite formation in tensile straining of an austenitic 15Cr-9Mn–Ni–Cu stainless steel. Mater Sci Eng A 578:408–416. https://doi.org/10.1016/j.msea.2013.04.107

Popa NC, Balzar D (2012) Elastic strain and stress determination by Rietveld refinement: generalized treatment for textured polycrystals for all Laue classes. J Appl Crystallogr 45(4):838–839. https://doi.org/10.1107/S0021889812024879

Yonezawa T, Suzuki K, Ooki S, Hashimoto A (2013) The effect of chemical composition and heat treatment conditions on stacking fault energy for Fe–Cr–Ni austenitic stainless steel. Metall Mater Trans A 44(13):5884–5896. https://doi.org/10.1007/s11661-013-1943-0

Gavriljuk V, Petrov Y, Shanina B (2006) Effect of nitrogen on the electron structure and stacking fault energy in austenitic steels. Script Mater 55(6):537–540. https://doi.org/10.1016/j.scriptamat.2006.05.025

Talonen J, Hänninen H (2007) Formation of shear bands and strain-induced martensite during plastic deformation of metastable austenitic stainless steels. Acta Mater 55(18):6108–6118. https://doi.org/10.1016/j.actamat.2007.07.015

Talonen J (2007) Effect of strain-induced martensite transformation on mechanical properties of metastable austenitic stainless steel. Dissertation, Helsinki University of Technology

Behjati P, Najafizadeh A (2011) Role of chemical driving force in martensitic transformations of high-purity Fe–Cr–Ni alloys. Metall Mater Trans A 42(12):3752–3760. https://doi.org/10.1007/s11661-011-0769-x

Kibey S, Liu JB, Curtis MJ, Johnson DD, Sehitoglu H (2006) Effect of nitrogen on generalized stacking fault energy and stacking fault widths in high nitrogen steels. Acta Mater 54(11):2991–3001. https://doi.org/10.1016/j.actamat.2006.02.048

Dorn JE (1963) Thermodynamics of stacking faults in binary alloys. Acta Metall 3:218–219. https://doi.org/10.1016/0001-6160(63)90216-5

Murugesan S, Kuppusami P (2012) Mohandas E Vijayalakshmi M, X-ray diffraction Rietveld analysis of cold worked austenitic stainless steel. Mater Lett 67(1):173–176. https://doi.org/10.1016/j.matlet.2011.09.065

Weber S, Martin M, Theisen W (2011) Lean-alloyed austenitic stainless steel with high resistance against hydrogen environment embrittlement. Mater Sci Eng A 528(25–26):7688–7695. https://doi.org/10.1016/j.msea.2011.06.049

Martin M, Weber S, Izawa C, Wagner S, Pundt A, Theisen W (2011) Influence of machining-induced martensite on hydrogen-assisted fracture of AISI type 304 austenitic stainless steel. Int J Hydrogen Energy 36(17):11195–11206. https://doi.org/10.1016/j.ijhydene.2011.05.133

Mosecker L, Pierce DT, Schwedt A, Beighmohamadi M, Mayer J, Bleck W, Wittig JE (2015) Temperature effect on deformation mechanisms and mechanical properties of a high manganese C+N alloyed austenitic stainless steel. Mater Sci Eng A 642:71–83. https://doi.org/10.1016/j.msea.2015.06.047

Remy L, Pineau A, Thomas B (1978) Temperature dependence of stacking fault energy in close-packed metals and alloys. Mater Sci Eng 36:47–63. https://doi.org/10.1016/0025-5416(78)90194-5

Asghari A, Zarei-Hanzaki A, Eskandari M (2013) Temperature dependence of plastic deformation mechanisms in a modified transformation-twinning induced plasticity steel. Mater Sci Eng A 579:150–156. https://doi.org/10.1016/j.msea.2013.04.106

Doherty RD, Hughes DA, Humphreys FJ, Jonas JJ, Juul Jensen D, Kassner ME, King WE, McNelley TR, McQueen HJ, Rollett AD (1997) Current issues in recrystallization: a review. Mater Sci Eng 238:219–274

Latanision RM, Ruff J (1971) The temperature dependence of stacking fault energy in Fe–Cr–Ni Alloy. Metall Mater Trans A(2):505–509

Lecroisey F, Pineau A (1972) Martensitic transformations induced by plastic deformation in the Fe–Ni–Cr–C System. Metall Mater Trans A(3):387–396

Unfried-Silgado J, Wu L, Furlan Ferreira F, Garzon CM, Ramirez AJ (2012) Stacking fault energy measurements in solid solution strengthened Ni–Cr–Fe alloys using synchrotron radiation. Mater Sci Eng A(558):70–75. https://doi.org/10.1016/j.msea.2012.07.072

Wasilewski RJ (1967) B.C.C. stacking fault energies. J Appl Crystallogr 1:45–47

Tisone TC, Sundahl RC, Chin GY (1970) The stacking fault energy in noble metal alloys. Metall Mater Trans A(1):1561–1567

Sambongi T (1965) Stacking fault probabilities of nickel-iron alloys. J Phys Soc 8:1370–1374

Funding

This study was funded by Deutsche Forschungsgemeinschaft, Project-No. TH 531/19-1.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Walter, M., Mujica Roncery, L., Weber, S. et al. XRD measurement of stacking fault energy of Cr–Ni austenitic steels: influence of temperature and alloying elements. J Mater Sci 55, 13424–13437 (2020). https://doi.org/10.1007/s10853-020-04953-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-020-04953-4