Abstract

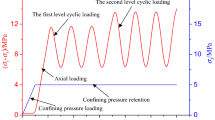

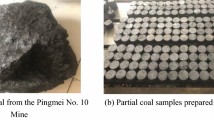

This paper presents an experimental investigation of the fractal characteristics about surface cracks of failed coal specimens in triaxial conventional compression and cyclic loading tests. The fractal characteristics under different confining pressures, test types, and cyclic loading frequencies are summarized and analyzed. The main achievements are as follows: (1) Under the same confining pressure, the average fractal value of failed coal specimen surface cracks in conventional compression test is obviously smaller than that in cyclic loading test for obvious differences in crack propagation modes between the two tests. Conventional compression test is beneficial to the development of large cracks in coal specimen, while cyclic loading test is helpful to the growth of small cracks. (2) The average fractal value of failed coal specimen surface cracks in cyclic loading test with the frequency of 0.25 Hz is slightly larger than that in cyclic loading test with the frequency of 0.5 Hz. The reason is that the lower the frequency of cyclic loading, the more surface cracks generated in coal specimen under the same cyclic number. (3) Whether in triaxial conventional compression test or cyclic loading test, the average fractal value of failed coal specimen surface cracks under the confining pressure of 5 MPa is larger than that under the confining pressure of 10 MPa because of the higher the confining pressure, the stronger the restriction of crack growth.

Similar content being viewed by others

References

Ai T, Zhang R, Zhou HW et al (2014) Box-counting methods to directly estimate the fractal dimension of a rock surface. Appl Surf Sci 314:610–621

Chen K, Wang WK, Guo X et al (2017) Research on fractal characteristics of sandstone fracture under uniaxial compression in urumpi mining area. China Coal 43(2):52–55

Deng Y, Chen M, ** Y et al (2016) Theoretical analysis and experimental research on the energy dissipation of rock crushing based on fractal theory. J Nat Gas Sci Eng 33:231–239

Engel P (1983) The fractal geometry of nature (book review). Sciences 23(5):63–68

Huang DM, Chang XK, Lin XF et al (2014) The fractal dimension of rock crack under uniaxial compression. J Shandong Univ Sci Technol (Nat Sci) 33(2):58–62

Kong XG, Wang EY, Hu SB et al (2016) Fractal characteristics and acoustic emission of coal containing methane in triaxial compression failure. J Appl Geophys 124:139–147

Li YY (2015) Deformation and failure characteristics and energy evolution laws of coal-rock mass under mining influence. Doctor of Philosophy from Shandong University of Science and Technology, Qingdao, pp 8–9

Li YY, Zhang SC, Zhang X (2018) Classification and fractal characteristics of coal rock fragments under uniaxial cyclic loading conditions. Arab J Geosci 11(9):201

Liu CX (2004) Analysis and application for rock damage mechanism and size effect of joints distribution with nonlinear dynamics. Doctor of Philosophy from Shandong University of Science and Technology, Qingdao, pp 3–53

Lu BY (2007) Research fractal geometry behavior characteristics and fractal mechanism of rock material damage evolution. Master of Philosophy from Guizhou University, Guiyang, pp 2–5

Ma DP (2016) Basic experiment research of failure mechanism and precursory characteristics of rock under triaxial unloading confining pressure. Doctor of Philosophy from Shandong University of Science and Technology, Qingdao, pp 105–109

Miao TJ, Yu BM, Duan YG et al (2015) A fractal analysis of permeability for fractured rocks. Int J Heat Mass Transf 81:75–80

**a YY, Lin MQ, Liao LL et al (2014) Fractal characteristics analysis of fragments from rockburst tests of large-diameter specimens. Chin J Rock Mech Eng 33(7):1358–1365

**e HP, Wang JA (1999) Direct fractal measurement of fracture surfaces. Int J Solids Struct 36(20):3073–3084

Yang RS, Xu P (2017) Fractal study of media damage under blasting loading. J China Coal Soc 42(12):3065–3071

Yang LL, Xu WY, Meng QX et al (2017) Investigation on joint rock strength based on fractal theory. J Cent South Univ 24:1619–1626

Zhang JX, Li M, Liu Z et al (2017) Fractal characteristics of crushed particles of coal gangue under compaction. Powder Technol 305:12–18

Zhang XY, Cai YY, Zhou HR et al (2019) Shear behaviors and fractal dimensions of carol sand at large shear strain. Rock Soil Mech 40(2):1–7

Zhao YH (1998) Crack pattern evolution and a fractal damage constitutive model for rock. Int J Rock Mech Min Sci 35(3):349–366

Zhao HB, Zhang H, Li HH et al (2017) Formation and fractal characteristics of main fracture surface of red sandstone under restrictive shear creep. Int J Rock Mech Min Sci 98:181–190

Acknowledegments

This research was supported by the project of Shandong Province Higher Educational Science and Technology Program (Grant No. J18KA195).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Duan, H., Zhang, S. Fractal Characteristics of Coal Specimens’ Surface Cracks in Triaxial Conventional Compression and Cyclic Loading Tests. Geotech Geol Eng 38, 19–29 (2020). https://doi.org/10.1007/s10706-019-00876-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10706-019-00876-3