Abstract

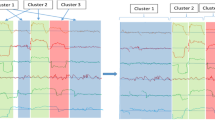

For complex industrial processes with frequent operating characteristics, process data types will be infinite due to the randomness and uncertainty of operation. Additionally, the process data follow serious non-Gaussian distribution. In this paper, an efficient q-nearest-neighbor standardization principal component analysis (q-NNS PCA) based on-line modeling method is proposed to handle complex data distributions and incursive frequent operation shifts. Due to the limitation of initial modeling data, the modeling data structure needs to be continuously replenished with accumulation of new normal batches. The on-line modeling method is proposed to avoid the complexity of model updating and establishment of massive offline models as well as the difficulty of the multiple models selection. For each test sample online, the q-NNS method can search its modeling data coming from the same operation to establish monitoring model, which settles non-Gaussian distribution problem. The proposed method is illustrated with a 120t ladle furnace (LF) steelmaking process. The comparison of monitoring results demonstrates that the proposed method is superior to multiple PCA and MKPCA methods and can achieve accurate and prompt detection of various types of faults in multi-operation processes.

Similar content being viewed by others

References

Wang, Y.J., Jia, M.X., Mao, Z.Z.: A fast monitoring method for multiple operating batch processes with incomplete modeling data types. J. Ind. Eng. Chem. 21, 328–337 (2015)

Pourbabaee, B., Meskin, N., Khorasani, K.: Sensor fault detection, isolation, and identification using multiple-model-based hybrid kalman filter for gas turbine engines. IEEE Trans. Control Syst. Technol. 24(4), 1184–1200 (2016)

Villez, K., Habermacher, J.: Shape anomaly detection for process monitoring of a sequencing batch reactor. Comput. Chem. Eng. 91, 365–379 (2016)

Wang, Y.J., Sun, F.M.: Multiple dynamic kernel clustering based online monitoring for batch processes. CIESC J. 65(12), 4095 (2014)

Zhao, S.Y., Huang, B., Liu, F.: Detection and diagnosis of multiple faults with uncertain modeling parameters. IEEE Trans. Control Syst. Technol. 25(5), 1873–1881 (2017)

Zhu, J., Ge, Z., Song, Z.: Non-Gaussian Industrial process monitoring with probabilistic Independent component analysis. IEEE Trans. Autom. Sci. Eng. 14(2), 1309–1319 (2017)

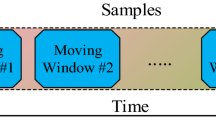

Zhang, S.M., Zhao, C.H., Wang, S., Wang, F.L.: Pseudo time-slice construction using variable moving window-k nearest neighbor (VMW-kNN) rule for sequential uneven phase division and batch process monitoring. Ind. Eng. Chem. Res. 56(3), 728–740 (2017)

Jong-Min, L., ChangKyoo, Y., In-Beum, L.: Fault detection of batch processes using multi-way kernel principal component analysis. Comput. Chem. Eng. 28, 1837–1847 (2004)

Kim, M.H., Yoo, C.K.: Multivariate monitoring for time-derivative non-Gaussian batch process. Korean J. Chem. Eng. 25(5), 947–954 (2008)

Choi, S.W., Lee, I.B.: Nonlinear dynamic process monitoring based on dynamic kernel PCA. Chem. Eng. Sci. 59, 5897–5908 (2004)

Yu, J., Qin, S.J.: Multiway gaussian mixture model based multiphase batch process monitoring. Ind. Eng. Chem. Res. 48, 8585–8594 (2009)

Liu, J.L.: Modeling a large-scale nonlinear system using adaptive Takagi-Sugeno fuzzy model on PCA subspace. Ind. Eng. Chem. Res. 46, 788–800 (2007)

Wang, X., Kruger, U., Irwin, G.W.: Process monitoring approach using fast moving window PCA. Ind. Eng. Chem. Res. 44, 5691–5702 (2005)

Zhao, C.H., Wang, F.L., Gao, F.R., et al.: Adaptive monitoring method for batch processes based on phase dissimilarity updating with limited modeling data. Ind. Eng. Chem. Res. 46, 4943–4953 (2007)

Petković, M., Rapaić, M.R., Jeličić, Z.D., et al.: On-line adaptive clustering for process monitoring and fault detection. Expert Syst. Appl. 39, 10226–10235 (2012)

Tong, C.D., Palazoglu, A., Yan, X.F.: An adaptive multimode process monitoring strategy based on mode clustering and mode unfolding. J. Process Control 23, 1497–1507 (2013)

Ma, Y.X., Shi, H.B., Wang, M.L.: Adaptive local outlier probability for dynamic process monitoring. Chin. J. Chem. Eng. 22(7), 820–827 (2014)

Zhang, X., Xu, Z.: Hesitant fuzzy agglomerative hierarchical clustering algorithms. Int. J. Syst. Sci. 46(3), 562–576 (2015)

Almeida, J.A.S., Barbosa, L.M.S., Pais, A.A.C.C., et al.: Improving hierarchical cluster analysis: a new method with outlier detection and automatic clustering. Chemom. Intell. Lab. Syst. 87, 208–217 (2007)

Kleiner, F.W.: Tree decomposition-based indexing for efficient shortest path and nearest neighbors query answering on graphs. J. Comput. Syst. Sci. 82(1), 23–44 (2016)

Lv, W., Mao, Z., Yuan, P.: Ladle furnace steel temperature prediction model based on partial linear regularization networks with sparse representation. Steel Res. Int. 83, 288–296 (2012)

Zhou, P., Song, H.D., Wang, H., et al.: Data-driven nonlinear subspace modeling for prediction and control of molten iron quality indices in blast furnace ironmaking. IEEE Trans. Control Syst. Technol. 25(5), 1761–1774 (2017)

Li, Y., Mao, Z., Wang, Y., et al.: Model predictive control synthesis approach of electrode regulator system for electric arc furnace. J. Iron. Steel Res. Int. 11, 20–25 (2011)

Acknowledgements

The authors acknowledge the National Natural Science Foundation of China (Grant: 61503169, 61572244, 61603164), Liaoning province innovation talent project (LR2016057), the Natural Science Foundation of Liaoning province (Grant: 2015020102).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, Y., Sun, F. & Li, D. On-line modeling and monitoring for multi-operation batch processes with infinite data types. Cluster Comput 22 (Suppl 6), 14855–14866 (2019). https://doi.org/10.1007/s10586-018-2426-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10586-018-2426-2