Abstract

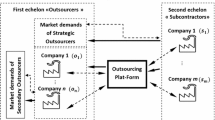

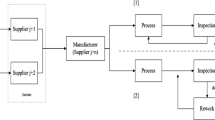

This paper presents a framework for designing a closed-loop green supply chain network (CLGSCN) that incorporates a redundancy strategy for maximum reliability and eco-friendliness. The network consists of production centers, repairs, and spare parts, with maintenance outsourced to ensure that spare parts circulate within the network for as long as possible. The proposed multi-objective mixed-integer program considers environmental considerations, service costs, routing decisions, cycle times, and assignments, with active and cold standby strategies for maximum reliability. A hybrid heuristics algorithm and multi-choice meta-goal programming with utility function are applied to solve the multi-objective model. The case study demonstrates the applicability of the model in real-world scenarios, offering valuable insights for optimized spare-part supply for maintenance and delivery. Sensitivity analyses show that the objectives are highly sensitive to the parameters, including the failure rate, demand, and reliability of the components, and results show an approximate decrease of 15.3% in the total cost and an increase of 2.83% in eco-friendly parts and finally increase of 11.25% in reliability with active standby strategy. Overall, this paper contributes to the field of supply chain management for advanced manufacturing systems both theoretically and practically, with potential benefits for businesses and society.

Similar content being viewed by others

Data availability

The related data have been presented in the manuscript.

References

AboueiArdakan M, Hamadani AZ (2014) Reliability–redundancy allocation problem with cold-standby redundancy strategy. Simul Model Pract Theory 42:107–118

AboueiArdakan M, Sima M, ZeinalHamadani A, Coit DW (2016) A novel strategy for redundant components in reliability-redundancy allocation problems. IIE Trans 48(11):1043–1057

Ahmadizar F, Soltanpanah H (2011) Reliability optimization of a series system with multiple-choice and budget constraints using an efficient ant colony approach. Expert Syst Appl 38(4):3640–3646

Ahmed MN (2019) The use of performance-based contracting in managing the outsourcing of a reliability-centered maintenance program: A case study. J Qual Maint Eng 26(4):526–554

Amari SV, Dill G (2009) A new method for reliability analysis of standby systems. In Reliability and Maintainability Symposium, 2009. RAMS 2009. Annual (pp. 417–422). IEEE

Bhattacharya D, Roychowdhury S (2014) A constrained cost minimizing redundancy allocation problem in coherent systems with non-overlap** subsystems. Adv Ind Eng Manag 3(3):1–6

Cai W, Liu C, Jia S, Chan FT, Ma M, Ma X (2020) An energy-based sustainability evaluation method for outsourcing machining resources. J Clean Prod 245:118849

Chambari A, Najafi AA, Rahmati SHA, Karimi A (2013) An efficient simulated annealing algorithm for the redundancy allocation problem with a choice of redundancy strategies. Reliab Eng Syst Saf 119:158–164

Chaleshigar Kordasiabi M, Gholizadeh H, Khakifirooz M, Fathi M (2023) Robust-heuristic-based optimisation for an engine oil sustainable supply chain network under uncertainty. Int J Prod Res 61(4):1313–1340

Chen TC (2006) IAs based approach for reliability redundancy allocation problems. Appl Math Comput 182(2):1556–1567

Ebrahimi M, Tavakkoli-Moghaddam R (2020) Benders decomposition algorithm for a green closed-loop supply chain under a build-to-order environment. J Ind Syst Eng 13:102–111

Feizollahi MJ, Soltani R, Feyzollahi H (2015) The robust cold standby redundancy allocation in series-parallel systems with budgeted uncertainty. IEEE Trans Reliab 64(2):799–806

Garg HARISH, Sharma SP (2013) Reliability-redundancy allocation problem of pharmaceutical plant. J Eng Sci Technol 8(2):190–198

Garg H, Rani M, Sharma SP, Vishwakarma Y (2014) Bi-objective optimization of the reliability-redundancy allocation problem for series-parallel system. J Manuf Syst 33(3):335–347

Ghahremani-Nahr J, Kian R, Sabet E (2019) A robust fuzzy mathematical programming model for the closed-loop supply chain network design and a whale optimization solution algorithm. Expert Syst Appl 116:454–471

Ghomi-Avili M, Naeini SGJ, Tavakkoli-Moghaddam R, Jabbarzadeh A (2018) A fuzzy pricing model for a green competitive closed-loop supply chain network design in the presence of disruptions. J Clean Prod 188:425–442

Gholizadeh H, Jahani H, Abareshi A, Goh M (2021) Sustainable closed-loop supply chain for dairy industry with robust and heuristic optimization. Comput Ind Eng 157:107324

Gholizadeh H, Fazlollahtabar H (2020) Robust optimization and modified genetic algorithm for a closed loop green supply chain under uncertainty: Case study in melting industry. Comput Ind Eng 147:106653

Gholizadeh H, Goh M, Fazlollahtabar H, Mamashli Z (2022) Modelling uncertainty in sustainable-green integrated reverse logistics network using metaheuristics optimization. Comput Ind Eng 163:107828

Ghasemi P, Goodarzian F, Abraham A (2022) A new humanitarian relief logistic network for multi-objective optimization under stochastic programming. Appl Intell 52(12):13729–13762

Geng D, Innes J, Wu W, Wang G (2021) Impacts of COVID-19 pandemic on urban park visitation: a global analysis. J For Res 32:553–567

Guilani PP, Azimi P, Niaki STA, Niaki SAA (2016) Redundancy allocation problem of a system with increasing failure rates of components based on Weibull distribution: A simulation-based optimization approach. Reliab Eng Syst Saf 152:187–196

Guo B, Gunn SR, Damper RI, Nelson JD (2006) Band selection for hyperspectral image classification using mutual information. IEEE Geoscience and Remote Sensing Letters 3(4):522–526

Guo J, Wang Z, Zheng M, Wang Y (2014) Uncertain multiobjective redundancy allocation problem of repairable systems based on artificial bee colony algorithm. Chin J Aeronaut 27(6):1477–1487

Ha C, Kuo W (2006) Reliability redundancy allocation: An improved realization for nonconvex nonlinear programming problems. Eur J Oper Res 171(1):24–38

Hadipour H, Amiri M, Sharifi M (2019) Redundancy allocation in series-parallel systems under warm standby and active components in repairable subsystems. Reliab Eng Syst Saf 192:106048

Haoues M, Dahane M, Mouss KN (2021) Capacity planning with outsourcing opportunities under reliability and maintenance constraints. Int J Ind Syst Eng 37(3):382–409

He Q, Hu X, Ren H, Zhang H (2015) A novel artificial fish swarm algorithm for solving large-scale reliability–redundancy application problem. ISA Trans 59:105–113

Huang CL (2015) A particle-based simplified swarm optimization algorithm for reliability redundancy allocation problems. Reliab Eng Syst Saf 142:221–230

Hsieh TJ (2022) A simple hybrid redundancy strategy accompanied by simplified swarm optimization for the reliability–redundancy allocation problem. Eng Optim 54(3):369–386

Hsieh TJ, Yeh WC (2012) Penalty guided bees search for redundancy allocation problems with a mix of components in series–parallel systems. Comput Oper Res 39(11):2688–2704

Hsieh YC, You PS (2011) An effective immune based two-phase approach for the optimal reliability–redundancy allocation problem. Appl Math Comput 218(4):1297–1307

Juybari MN, AboueiArdakan M, Davari-Ardakani H (2019) A penalty-guided fractal search algorithm for reliability–redundancy allocation problems with cold-standby strategy. Proc Inst Mech Eng, Part O: J Risk Reliab 233(5):775–790

Ji Y, Li H, Zhang H (2022) Risk-averse two-stage stochastic minimum cost consensus models with asymmetric adjustment cost. Group Decis Negot 31:261–291

Jahani H, Gholizadeh H (2022) A flexible closed loop supply chain design considering multi-stage manufacturing and queuing based inventory optimization. IFAC-PapersOnLine 55(10):1325–1330

Kafiabad ST, Zanjani MK, Nourelfath M (2020) Integrated planning of operations and on-job training in maintenance logistics networks. Reliab Eng Syst Saf 199:106922

Kanagaraj G, Ponnambalam SG, Jawahar N (2013) A hybrid cuckoo search and genetic algorithm for reliability–redundancy allocation problems. Comput Ind Eng 66(4):1115–1124

Kayedpour F, Amiri M, Rafizadeh M, Nia AS (2017) Multi-objective redundancy allocation problem for a system with repairable components considering instantaneous availability and strategy selection. Reliab Eng Syst Saf 160:11–20

Khoei MA, Aria SS, Gholizadeh H, Goh M, Cheikhrouhou N (2023) Big data-driven optimization for sustainable reverse logistics network design. J Ambient Intell Humaniz Comput 14(8):10867–10882

Khalili-Damghani K, Abtahi AR, Tavana M (2013) A new multi-objective particle swarm optimization method for solving reliability redundancy allocation problems. Reliab Eng Syst Saf 111:58–75

Kim H, Kim P (2017) Reliability–redundancy allocation problem considering optimal redundancy strategy using parallel genetic algorithm. Reliab Eng Syst Saf 159:153–160

Kim HS, Jeon GW (2012) A reliability optimization problem of system with mixed redundancy strategies. IE Interfaces 25(2):153–162

Levitin G, **ng L, Ben-Haim H, Dai Y (2013) Reliability of series-parallel systems with random failure propagation time. IEEE Trans Reliab 62(3):637–647

Liang YC, Lo MH (2010) Multi-objective redundancy allocation optimization using a variable neighborhood search algorithm. J Heuristics 16(3):511–535

Liu Y (2016) Improved bat algorithm for reliability-redundancy allocation problems. Int J Secur Appl 10(2):1–12

Mellal MA, Zio E (2020) System reliability-redundancy optimization with cold-standby strategy by an enhanced nest cuckoo optimization algorithm. Reliab Eng Syst Saf 201:106973

Mendoza CD, Penati V (2020) Joint evaluation of lateral transshipment policies, inventory control policies and maintenance strategies in the spare parts supply chain network: a simulation-based study. http://hdl.handle.net/10589/153752

Nahas N, Nourelfath M, Ait-Kadi D (2007) Coupling ant colony and the degraded ceiling algorithm for the redundancy allocation problem of series–parallel systems. Reliab Eng Syst Saf 92(2):211–222

Nayeri S, Torabi SA, Tavakoli M, Sazvar Z (2021) A multi-objective fuzzy robust stochastic model for designing a sustainable-resilient-responsive supply chain network. J Clean Prod 311:127691

Özçelik G, Faruk Yılmaz Ö, BetülYeni F (2021) Robust optimisation for ripple effect on reverse supply chain: an industrial case study. Int J Prod Res 59(1):245–264

Pourdarvish A, Ramezani Z (2013) Cold standby redundancy allocation in a multi-level series system by memetic algorithm. Int J Reliab Qual Saf Eng 20(03):1340007

Pourkarim Guilani P, Azimi P, Sharifi M, Amiri M (2019) Redundancy allocation problem with a mixed strategy for a system with k-out-of-n subsystems and time-dependent failure rates based on Weibull distribution: An optimization via simulation approach. Sci Iran 26(2):1023–1038

Pietrzykowski M, Woś B, Tylek P, Kwaśniewski D, Juliszewski T, Walczyk J, ... Tabor S (2021). Carbon sink potential and allocation in above-and below-ground biomass in willow coppice. J For Res, 32, 349–354

Qu S, Wei J, Wang Q, Li Y, ** X, Chaib L (2023) Robust minimum cost consensus models with various individual preference scenarios under unit adjustment cost uncertainty. Inf Fusion 89:510–526

Razavi N, Gholizadeh H, Nayeri S, Ashrafi TA (2021) A robust optimization model of the field hospitals in the sustainable blood supply chain in crisis logistics. J Oper Res Soc 72(12):2804–2828

Roy P, Mahapatra BS, Mahapatra GS, Roy PK (2014) Entropy based region reducing genetic algorithm for reliability redundancy allocation in interval environment. Expert Syst Appl 41(14):6147–6160

Raeisi D, JafarzadehGhoushchi S (2022) A robust fuzzy multi-objective location-routing problem for hazardous waste under uncertain conditions. Appl Intell 52(12):13435–13455

Sadjadi SJ, Soltani R (2015) Minimum–maximum regret redundancy allocation with the choice of redundancy strategy and multiple choice of component type under uncertainty. Comput Ind Eng 79:204–213

Saghih AMF, Modares A (2022) A new dynamic model to optimize the reliability of the series-parallel systems under warm standby components. J Ind Manag Optim 19(1):376–401

Sahebjamnia N, Fathollahi-Fard AM, Hajiaghaei-Keshteli M (2018) Sustainable tire closed-loop supply chain network design: Hybrid metaheuristic algorithms for large-scale networks. J Clean Prod 196:273–296

Samuel CN, Venkatadri U, Diallo C, Khatab A (2020) Robust closed-loop supply chain design with presorting, return quality and carbon emission considerations. J Clean Prod 247:119086

Sarkar A, Panja SC, Sarkar B (2011) Survey of maintenance policies for the last 50 years. Int J Softw Eng Appl 2(3):130–148

Sarada Y, Sangeetha S (2022) A δ-shock model for reengineering of a repairable supply chain using quasi renewal process. Communications in Statistics-Theory and Methods 51(18):6476-6501

Sazvar Z, Zokaee M, Tavakkoli-Moghaddam R, Salari SAS, Nayeri S (2021) Designing a sustainable closed-loop pharmaceutical supply chain in a competitive market considering demand uncertainty, manufacturer’s brand and waste management. Ann Oper Res 315:2057–2088

Sharifi M, Shahriyari M, Khajepour A, Mirtaheri SA (2021) Reliability optimization of a k-out-of-n series-parallel system with warm standby components. Scientia Iranica. https://doi.org/10.24200/sci.2021.56113.4591

Talafuse TP, Pohl EA (2015) A bat algorithm for the redundancy allocation problem. Eng Optim, 1–11. https://doi.org/10.1080/0305215X.2015.1076402

Valaei MR, Behnamian J (2017) Allocation and sequencing in 1-out-of-N heterogeneous cold-standby systems: multi-objective harmony search with dynamic parameters tuning. Reliab Eng Syst Saf 157:78–86

Wang L, Li LP (2012) A co-evolutionary differential evolution with harmony search for reliability–redundancy optimization. Expert Syst Appl 39(5):5271–5278

Wang W, Wu Z, **ong J, Xu Y (2018) Redundancy optimization of cold-standby systems under periodic inspection and maintenance. Reliab Eng Syst Saf 180:394–402

Wang W, **ong J, **e M (2015) Cold-standby redundancy allocation problem with degrading components. Int J Gen Syst 44(7–8):876–888

Wu P, Gao L, Zou D, Li S (2011) An improved particle swarm optimization algorithm for reliability problems. ISA Trans 50(1):71–81

Xu Y, Liao H (2015) Reliability analysis and redundancy allocation for a one-shot system containing multifunctional components. IEEE Trans Reliab 65(2):1045–1057

Yılmaz ÖF (2020) Examining additive manufacturing in supply chain context through an optimization model. Comput Ind Eng 142:106335

Yilmaz OF, Durmusoglu MB (2019) Multi-objective scheduling problem for hybrid manufacturing systems with walking workers. Int J Ind Eng 26(5):625–650

Yılmaz ÖF, Özçelik G, Yeni FB (2021) Ensuring sustainability in the reverse supply chain in case of the ripple effect: A two-stage stochastic optimization model. J Clean Prod 282:124548

Yeh WC, Hsieh TJ (2011) Solving reliability redundancy allocation problems using an artificial bee colony algorithm. Comput Oper Res 38(11):1465–1473

Zhang E, Chen Q (2016) Multi-objective reliability redundancy allocation in an interval environment using particle swarm optimization. Reliab Eng Syst Saf 145:83–92

Zhang E, Wu Y, Chen Q (2014) A practical approach for solving multi-objective reliability redundancy allocation problems using extended bare-bones particle swarm optimization. Reliab Eng Syst Saf 127:65–76

Zoulfaghari H, Hamadani AZ, AboueiArdakan M (2014) Bi-objective redundancy allocation problem for a system with mixed repairable and non-repairable components. ISA Trans 53(1):17–24

Zoulfaghari H, Hamadani A, AboueiArdakan M (2015) Multi-objective availability-redundancy allocation problem for a system with repairable and non-repairable components. Decis Sci Lett 4(3):289–302

Author information

Authors and Affiliations

Contributions

Hadi Gholizadeh: Conceptualization, Methodology, Soft-ware, Validation, Formal analysis, Investigation, Data curation, Writing – original draft.

Ali Falahati Taft: Methodology, Formal analysis, Project administration.

Farid Taheri: Visualization, Software.

Hamed Fazlollahtabar: Writing – review & editing, Supervision, Investigation.

Mark Goh: Writing – review & editing, Visualization, Supervision.

Zohreh Molaee: Formal analysis, Methodology.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Conflicts of interest/Competing interests

The authors declare that there is no Conflicts of interest/Competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Gholizadeh, H., Taft, A.F., Taheri, F. et al. Designing a closed-loop green outsourced maintenance supply chain network for advanced manufacturing systems with redundancy strategy and eco-friendly parts. Appl Intell 53, 23905–23928 (2023). https://doi.org/10.1007/s10489-023-04821-z

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10489-023-04821-z