Abstract

We present an experimental investigation on the flow and clogging of bi-disperse mixtures of coarse and fine grains of different densities passing through small orifices. We vary the density ratio (coarse/fine) from 1.87 down to 0.79 by using amaranth seeds, glass and ceramic beads of similar size as the fine species in combination with 2.0 mm glass beads as the coarse grains. We analyzed the effect of the density ratio on the effective flow rate of the coarse species, the segregation during flow and the clogging for a range of orifice diameters. As in previous studies, the flow of the coarse grains is facilitated by the fine species, which prevents clogging. We show that the effective flow rate of the coarse species is virtually independent of the density ratio. These results suggest that in practical applications with the goal of clogging reduction, the density of the fine species used to ease the flow is not a relevant parameter and can be selected based on practical or economic constraints.

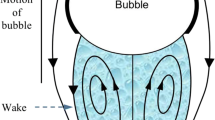

Graphic abstract

Schematic diagram of the flow of large grains through a small orifice when they are diluted in a mixture with fine grains

Similar content being viewed by others

Data availibility

Data sets generated during the current study are available from the corresponding author on reasonable request.

References

Janda, A., Zuriguel, I., Maza, D.: Flow rate of particles through apertures obtained from self-similar density and velocity profiles. Phys. Rev. Lett. 108(24), 248001 (2012). https://doi.org/10.1103/PhysRevLett.108.248001

Jaeger, H.M., Nagel, S.R., Behringer, R.P.: The physics of granular materials. Phys. Today 49(4), 32–39 (1996). https://doi.org/10.1063/1.881494

Campbell, C.S.: Granular material flows-an overview. Powder Technol. 162(3), 208–229 (2006). https://doi.org/10.1016/j.powtec.2005.12.008

Mankoc, C., Janda, A., Arévalo, R., Pastor, J., Zuriguel, I., Garcimartín, A., Maza, D.: The flow rate of granular materials through an orifice. Granul. Matter 9, 407–414 (2007). https://doi.org/10.1007/s10035-007-0062-2

Arteaga, P., Tüüzün, U.: Flow of binary mixtures of equal-density granules in hoppers—size segregation, flowing density and discharge rates. Chem. Eng. Sci. 45(1), 205–223 (1990). https://doi.org/10.1016/0009-2509(90)87093-8

Benyamine, M., Djermane, M., Dalloz-Dubrujeaud, B., Aussillous, P.: Discharge flow of a bidisperse granular media from a silo. Phys. Rev. E 90, 032201 (2014). https://doi.org/10.1103/PhysRevE.90.032201

Madrid, M., Asencio, K., Maza, D.: Silo discharge of binary granular mixtures. Phys. Rev. E 96, 022904 (2017). https://doi.org/10.1103/PhysRevE.96.022904

Zhang, Z., Liu, Y., Zheng, B., Li, R., Sun, P.: Discharge characteristics of binary particles in a rectangular hopper with inclined bottom. Comput. Part. Mech. 8, 315 (2021). https://doi.org/10.1007/s40571-020-00332-7

Zhou, Y., Ruyer, P., Aussillous, P.: Discharge flow of a bidisperse granular media from a silo: discrete particle simulations. Phys. Rev. E 92, 062204 (2015). https://doi.org/10.1103/PhysRevE.92.062204

Zuriguel, I., Parisi, D.R., Hidalgo, R.C., Lozano, C., Janda, A., Gago, P.A., Peralta, J.P., Ferrer, L.M., Pugnaloni, L.A., Clément, E.: Clogging transition of many-particle systems flowing through bottlenecks. Sci. Rep. 4, 7324 (2014). https://doi.org/10.1038/srep07324

Hunt, M.L., Weathers, R.C., Lee, A.T., Brennen, C.E., Wassgren, C.R.: Effects of horizontal vibration on hopper flows of granular materials. Phys. Fluids 11(1), 68–75 (1999). https://doi.org/10.1063/1.869903

Janda, A., Maza, D., Garcimartín, A., Kolb, E., Lanuza, J., Clément, E.: Unjamming a granular hopper by vibration. EPL 87(2), 24002 (2009). https://doi.org/10.1209/0295-5075/87/24002

Mankoc, C., Garcimartín, A., Zuriguel, I., Maza, D., Pugnaloni, L.A.: Role of vibrations in the jamming and unjamming of grains discharging from a silo. Phys. Rev. E 80, 011309 (2009). https://doi.org/10.1103/PhysRevE.80.011309

Lozano, C., Lumay, G., Zuriguel, I., Hidalgo, R., Garcimartín, A.: Breaking arches with vibrations: the role of defects. Phys. Rev. Lett. 109(6), 068001 (2012). https://doi.org/10.1103/PhysRevLett.109.068001

Dave, R.N., Wu, C.-Y., Chaudhuri, B., Watano, S.: Magnetically mediated flow enhancement for controlled powder discharge of cohesive powders. Powder Technol. 112(1–2), 111–125 (2000). https://doi.org/10.1016/S0032-5910(99)00312-5

Lumay, G., Schockmel, J., Henández-Enríquez, D., Dorbolo, S., Vandewalle, N., Pacheco-Vazquez, F.: Flow of magnetic repelling grains in a two-dimensional silo. Pap. Phys. 7, 070013 (2015). https://doi.org/10.4279/pip.070013

Carlevaro, C.M., Kuperman, M.N., Bouzat, S., Pugnaloni, L.A., Madrid, M.A.: On the use of magnetic particles to enhance the flow of vibrated grains through narrow apertures. Granul. Matter 24, 51 (2022). https://doi.org/10.1007/s10035-022-01209-7

To, K., Tai, H.-T.: Flow and clog in a silo with oscillating exit. Phys. Rev. E 96, 032906 (2017). https://doi.org/10.1103/PhysRevE.96.032906

Zuriguel, I., Janda, A., Garcimartín, A., Lozano, C., Arévalo, R., Maza, D.: Silo clogging reduction by the presence of an obstacle. Phys. Rev. Lett. 107(27), 278001 (2011). https://doi.org/10.1103/PhysRevLett.107.278001

Endo, K., Reddy, K.A., Katsuragi, H.: Obstacle-shape effect in a two-dimensional granular silo flow field. Phys. Rev. Fluids 2(9), 094302 (2017). https://doi.org/10.1103/PhysRevFluids.2.094302

Madrid, M.A., Carlevaro, C.M., Pugnaloni, L.A., Kuperman, M., Bouzat, S.: Enhancement of the flow of vibrated grains through narrow apertures by addition of small particles. Phys. Rev. E 103, L030901 (2021). https://doi.org/10.1103/PhysRevE.103.L030901

Gharat, S.H., Pugnaloni, L.A.: Augmented flow and reduced clogging of particles passing through small apertures by addition of fine grains. Powder Technol. 427, 118695 (2023). https://doi.org/10.1016/j.powtec.2023.118695

Reddy, A. V. K., Kumar, Sonu, Reddy, K. A.: Granular particle-shape heterogeneous mixtures discharging through a silo. J. Fluid Mech. 912, A22 (2021). https://doi.org/10.1017/jfm.2020.1071

Zablotsky, A., et al.: (unpublished)

Goldberg, E., Carlevaro, C.M., Pugnaloni, L.A.: Flow rate of polygonal grains through a bottleneck: interplay between shape and size. Pap. Phys. 7, 070016 (2015). https://doi.org/10.4279/PIP.070016

Goldberg, E., Carlevaro, C.M., Pugnaloni, L.A.: Clogging in two-dimensions: effect of particle shape. J. Stat. Mech. Theory Exp. (2018). https://doi.org/10.1088/1742-5468/aae84b

Sepúlveda, N., Melo, F., Vivanco, F.: Effects of grain shape on the response of a two-dimensional granular material under constant shear rate. Phys. Rev. E 90, 052202 (2014). https://doi.org/10.1103/PhysRevE.90.052202

Nedderman, R.M.: Statics and Kinematics of Granular Materials. Cambridge University Press, Cambridge (2005)

Beverloo, W.A., Leniger, H.A., Van de Velde, J.J.: The flow of granular solids through orifices. Chem. Eng. Sci. 15(3), 260–269 (1961). https://doi.org/10.1016/0009-2509(61)85030-6

Ghadiri, M., Geldart, D., Pilgrim, J.A.: Mixing of binary systems of solids differing in particle size or density. Powder Technol. 57(3), 207–221 (1989)

Li, C., Li, X., Jiao, T., Hu, F., Sun, M., Huang, D.: Influence of grain bidispersity on dense granular flow in a two-dimensional hopper. Powder Technol. 401, 117271 (2022). https://doi.org/10.1016/j.powtec.2022.117271

Carlevaro, C.M., Kozlowski, R., Pugnaloni, L.A.: Flow rate in 2D silo discharge of binary granular mixtures: The role of ordering in monosized systems. Front. Soft Matter 4, 1340744 (2024). https://doi.org/10.3389/frsfm.2024.1340744

Humby, S., Tüzün, U., Yu, A.B.: Prediction of hopper discharge rates of binary granular mixtures. Chem. Eng. Sci. 53, 483–494 (1998). https://doi.org/10.1016/S0009-2509(97)00326-6

Zuriguel, I.: Clogging of granular materials in bottlenecks. Pap. Phys. 6, 060014 (2014). https://doi.org/10.4279/pip.060014

Zuriguel, I., Garcimartín, A., Maza, D., Pugnaloni, L. A., Pastor, J.: Jamming during the discharge of granular matter from a silo. Phys. Rev. E 71(5), 051303 (2005). https://doi.org/10.1103/PhysRevE.71.051303

Acknowledgements

This work was funded by CONICET (Consejo Nacional de Investigaciones Científicas y Técnicas, Argentina) under grant PIP-717.

Author information

Authors and Affiliations

Contributions

Conceptualization: SG and LP; Formal Analysis: SG and LP; Funding acquisition: LP; Investigation: SG and JM; Methodology: SG and JM; Writing-original draft: SG; Writing-review and editing: SG and LP.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no conflict of interest to declare that are relevant to the content of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Gharat, S.H., Montero, J. & Pugnaloni, L.A. Clogging reduction by addition of small particles of various material densities. Granular Matter 26, 76 (2024). https://doi.org/10.1007/s10035-024-01444-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10035-024-01444-0