Abstract

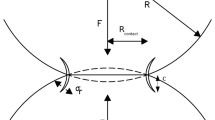

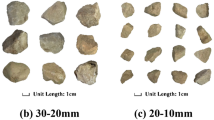

The size-dependent crushing strength of single rockfill particles affects the mechanical behavior of rockfill materials. Understanding and capturing the size effect of single particle crushing strength accurately is essential to investigate the gradation evolution and the mechanism of the scaling effect of rockfill materials. However, laboratory rockfill particle crushing tests are mainly carried out for sizes below 60 mm, which is much smaller than the size of rockfill particles in engineering. To study the topic, the crushing characteristics of limestone particles were investigated by laboratory single-particle crushing tests with a wide range of particle sizes (10–240 mm). The results show that the crushing strength of limestone particles obeyed the Weibull distribution and the particle size had a relatively small effect on the Weibull modulus. The characteristic strength of the particles decreased with increasing size, but it tended to stabilize when the particle size reached 240 mm. The exponential size effect equation was more suitable to describe the relationship between the characteristic strength and size of limestone particles. Then, a numerical simulation method was developed to capture the size effect of the crushing strength of rockfill particles by discounting the bond strength of the numerical sample with increasing particle size. In the approach, an exponential relationship between bond strength and particle size was adopted, which was derived based on the relationship between the characteristic strength and size of laboratory limestone particles.The simulation results of the distribution characteristics of the crushing strength of limestone particles with different size fractions are basically in agreement with the results of the laboratory tests, indicating that the method developed in this study can capture the size effect of the crushing strength of rockfill particles well. Finally, the damage evolution of rockfill particles was analyzed by capturing the broken bonds during loading.

Graphical abstract

Similar content being viewed by others

References

Varadarajan, A., Sharma, K.G., Venkatachalam, K., Gupta, A.K.: Testing and modeling two rockfill materials. J. Geotech. Geoenviron. 129(3), 206–218 (2003). https://doi.org/10.1061/(asce)1090-0241(2003)129:3(206)

Sevi, A., Ge, L.: Cyclic behaviors of railroad ballast within the parallel gradation scaling framework. J. Mater. Civ. Eng. 24(7), 797–804 (2012). https://doi.org/10.1061/(ASCE)MT.1943-5533.0000460

**ao, Y., Liu, H., Zhang, W.G., Liu, H.L., Yin, F., Wang, Y.Y.: Testing and modeling of rockfill materials: a review. J. Rock Mech. Geotech. 8(3), 415–522 (2016). https://doi.org/10.1016/j.jrmge.2015.09.009

Jia, J.S., Lino, M., **, F., Zheng, C.Y.: The cemented material dam: a new, environmentally friendly type of dam. Engineering 2, 490–497 (2016). https://doi.org/10.1016/J.ENG.2016.04.003

Li, Y.L., Li, K.P., Wen, L.F., Li, B., Liu, Y.H.: Safety standard for slopes of ultra-high earth and rock-fill dams in china based on reliability analysis. Int. J. Civ. Eng. 17, 1829–1844 (2019). https://doi.org/10.1007/s40999-019-00400-x

Alaei, E., Mahboubi, A.: A discrete model for simulating shear strength and deformation behaviour of rockfill material, considering the particle breakage phenomenon. Granular Matter 14, 707–717 (2012). https://doi.org/10.1007/s10035-012-0367-7

Frossard, E., Hu, W., Dano, C., Hicher, P.Y.: Rockfill shear strength evaluation: a rational method based on size effects. Géotechnique 62, 415–427 (2012). https://doi.org/10.1680/geot.10.P.079

Ovalle, C., Frossard, E., Dano, C., Hu, W., Maiolino, S., Hicher, P.Y.: The effect of size on the strength of coarse rock aggregates and large rockfill samples through experimental data. Acta Mech. 225(8), 2199–2216 (2014). https://doi.org/10.1007/s00707-014-1127-z

**ao, Y., Liu, H.L., Chen, Y.M., Jiang, J.S.: Strength and deformation of rockfill material based on large-scale triaxial compression tests. II: influence of particle breakage. J Geotech Geoenviron Eng 140, 04014071 (2014). https://doi.org/10.1061/(ASCE)GT.1943-5606.0001177

Liu, J.M., Zou, D.G., Kong, X.J., Liu, H.B.: Stress-dilatancy of Zi**pu gravel in triaxial compression tests. Sci. China Technol. Sc. 59(2), 214–224 (2016). https://doi.org/10.1007/s11431-015-5919-8

Xu, M., Hong, J., Song, E.X.: DEM study on the effect of particle breakage on the macro- and micro-behavior of rockfill sheared along different stress paths. Comput. Geotech. 89, 113–127 (2017). https://doi.org/10.1016/j.compgeo.2017.04.012

Wu, E.L., Zhu, J.G., Huang, W., Liu, Z.: Evolution law of particle breakage of coarse-grained soil during triaxial shearing. Chin. J. Geotech. Eng. 42, 2330–2335 (2020). https://doi.org/10.11779/CJGE202012021

Kong, X.J., Liu, J.M., Zou, D.G.: Scale effect of rockfill and multiple-scale triaxial test platform. Chin. J. Geotech. Eng. 38(11), 1941–1947 (2016). https://doi.org/10.11779/CJGE201611002

Xu, K., Zhou, W., Ma, G.: Influence of particle breakage on scale effect of filling characteristics of rockfill material. Chin. J. Geotech. Eng. 42(6), 1013–1022 (2020). https://doi.org/10.11779/CJGE202006004

Ning, F.W., Liu, J.M., Kong, X.J., Zou, D.G.: Critical state and grading evolution of rockfill material under different triaxial compression tests. Int. J. Geomech. 20, 04019154 (2020). https://doi.org/10.1061/(asce)gm.1943-5622.0001550

Shi, D., Zheng, L., Xue, J., Sun, J.: DEM modeling of particle breakage in silica sands under one-dimensional compression. Acta Mech. Solida Sin. 29, 78–94 (2016). https://doi.org/10.1016/S0894-9166(16)60008-3

Jiang, M.J.: New paradigm for modern soil mechanics: geomechanics from micro to macro. Chin. J. Geotech. Eng. 41(2), 195–254 (2019). https://doi.org/10.11779/CJGE201902001

Shen, Z., Jiang, M., Fang, N., Zhou, F.: A damage evolution law enriched by microscopic mechanisms for structured sand in mechanical loading. Acta Geotech. 14, 1905–1924 (2019). https://doi.org/10.1007/s11440-019-00841-7

Wang, J.W., Chi, S.C., Shao, X.Q., Zhou, X.X.: Determination of the mechanical parameters of the microstructure of rockfill materials in triaxial compression DEM simulation. Comput. Geotech. 137, 104265 (2021). https://doi.org/10.1016/j.compgeo.2021.104265

Shi, D., Cao, D., Xue, J., Deng, Y., Liang, Y.: DEM studies on the effect of particle breakage on the critical state behaviours of granular soils under undrained shear conditions. Acta Geotech. 17, 4865–4885 (2022). https://doi.org/10.1007/s11440-022-01580-y

Cui, H., **ao, Y., Shu, S., He, X., Liu, H.: A constitutive model incorporating particle breakage for gravelly soil-structure interface under cyclic loading. SCIENCE CHINA Technol. Sci. 65, 2846–2855 (2022). https://doi.org/10.1007/s11431-022-2100-6

**ao, Y., Zhao, C., Sun, Y., Wang, S., Wu, H., Chen, H., Liu, H.: Compression behavior of MICP-treated sand with various gradations. Acta Geotech. 16, 1391–1400 (2021). https://doi.org/10.1007/s11440-020-01116-2

**ao, Y., Chen, H., Stuedlein, A.W., Evans, T.M., Chu, J., Cheng, L., Jiang, N., Lin, H., Liu, H.L., Aboel-Naga, H.M.: Restraint of particle breakage by biotreatment method. J Geotech Geoenviron Eng 146, 04020123 (2020). https://doi.org/10.1061/(ASCE)GT.1943-5606.0002384

Weibull, W.: A statistical distribution function of wide applicability. J. Appl. Mech. 18(3), 293–297 (1951). https://doi.org/10.1115/1.4010337

Nakata, Y., Hyde, A.F.L., Hyodo, M., Murata, H.: A probabilistic approach to sand particle crushing in the triaxial test. Geotechnique 49(5), 567–583 (1999). https://doi.org/10.1680/geot.1999.49.5.567

McDowell, G.R.: Statistics of soil particle strength. Geotechnique 51(10), 897–900 (2001). https://doi.org/10.1680/geot.51.10.897.41061

Ergenzinger, C., Seifried, R., Eberhard, P.: A discrete element model predicting the strength of ballast stones. Comput. Struct. 108–109, 3–13 (2012). https://doi.org/10.1016/j.compstruc.2012.02.006

Huang, J., Xu, S., Yi, H., Hu, S.: Size effect on the compression breakage strengths of glass particles. Powder Technol. 268, 86–94 (2014). https://doi.org/10.1016/j.powtec.2014.08.037

Zhu, F., Zhao, J.D.: Interplays between particle shape and particle breakage in confined continuous crushing of granular media. Powder Technol. 378, 455–467 (2021). https://doi.org/10.1016/j.powtec.2020.10.020

Zhou, W., Yang, L., Ma, G., Chang, X., Lai, Z., Xu, K.: DEM analysis of the size effects on the behavior of crushable granular materials. Granular Matter 18, 64 (2016). https://doi.org/10.1007/s10035-016-0656-7

Zhou, W., Xu, K., Ma, G., Chang, X.: On the breakage function for constructing the fragment replacement modes. Particuology 44, 207–217 (2019). https://doi.org/10.1016/j.partic.2018.08.006

Huang, Q., Zhou, W., Ma, G., Ng, T.-T., Xu, K.: Experimental and numerical investigation of Weibullian behavior of grain crushing strength. Geosci. Front. 11, 401–411 (2020). https://doi.org/10.1016/j.gsf.2019.07.007

**ao, Y., Meng, M., Daouadji, A., Chen, Q., Wu, Z., Jiang, X.: Effects of particle size on crushing and deformation behaviors of rockfill materials. Geosci. Front. 11, 375–388 (2020). https://doi.org/10.1016/j.gsf.2018.10.010

Xu, M., **, D.H., Zhou, W.X.: An experimental study on the time-dependent behavior of crushable granular materials using 3D-printed particles. Acta Geotech. 17, 93–104 (2022). https://doi.org/10.1007/s11440-021-01232-7

Ciantia, M.O., Arroyo, M., Calvetti, F., Gens, A.: An approach to enhance efficiency of DEM modelling of soils with crushable grains. Geotechnique 65(2), 91–110 (2015). https://doi.org/10.1680/geot.13.P.218

Wang, P., Arson, C.: Discrete element modeling of shielding and size effects during single particle crushing. Comput. Geotech. 78, 227–236 (2016). https://doi.org/10.1016/j.compgeo.2016.04.003

Cil, M.B., Buscarnera, G., DEM,: assessment of scaling laws capturing the grain size dependence of yielding in granular soils. Granular Matter 18(36), 1–15 (2016). https://doi.org/10.1007/s10035-016-0638-9

Ma, G., Zhou, W., Chang, X.L., Chen, M.X.: A hybrid approach for modeling of breakable granular materials using combined finite-discrete element method. Granul. Matter 18, 7 (2016). https://doi.org/10.1007/s10035-016-0615-3

Wang, B., Martin, U., Rapp, S.: Discrete element modeling of the single-particle crushing test for ballast stones. Comput. Geotech. 88, 61–73 (2017). https://doi.org/10.1016/j.compgeo.2017.03.007

Zhu, F., Zhao, J.D.: A peridynamic investigation on crushing of sand particles. Géotechnique 69, 526–540 (2019). https://doi.org/10.1680/jgeot.17.P.274

Zhang, X., Liu, X., Xu, Y., Wang, G., Zang, M.: Fragmentation modes of single coral particles under uniaxial compression: microstructural insights. Constr Build Mater 344, 128186 (2022). https://doi.org/10.1016/j.conbuildmat.2022.128186

McDowell, G.R., Harireche, O.: Discrete element modelling of soil particle fracture. Géotechnique 52, 131–135 (2002). https://doi.org/10.1680/geot.2002.52.2.131

Zhou, M.J.: A crack theory-based bonded-particle model for rock particles considering size effects. Géotechnique Letters 11, 340–349 (2021). https://doi.org/10.1680/jgele.21.00022

Huillca, Y., Silva, M., Ovalle, C., Quezada, J.C., Carrasco, S., Villavicencio, G.E.: Modelling size effect on rock aggregates strength using a DEM bonded-cell model. Acta Geotech. 16, 699–709 (2021). https://doi.org/10.1007/s11440-020-01054-z

Cil, M.B., Sohn, C., Buscarnera, G.: DEM modeling of grain size effect in brittle granular soils. J. Eng. Mech. 146(3), 04019138 (2020). https://doi.org/10.1061/(ASCE)EM.1943-7889.0001713

Yan, S.H., Chi, S.C., Shao, X.Q., Guo, Y.: Efect of size and strain rate on particle strength and stress-strain properties of rockfll materials. Soil Dyn. Earthq. Eng. 162, 107422 (2022). https://doi.org/10.1016/j.soildyn.2022.107422

Guo, Y., Chi, S.C., Mi, X.F., Yan, S.H.: Experimental investigation of statistical characteristics of elastic mechanical parameters and strength indexes of rockfill particles. Granul. Matter 25(2), 30 (2023). https://doi.org/10.1007/s10035-022-01302-x

Jaeger, J.C.: Failure of rocks under tensile conditions. Int. J. Rock. Mech. Min. Sci. 4(2), 219–227 (1967). https://doi.org/10.1016/0148-9062(67)90046-0

Wang, J.W., Chi, S.C., Shao, X.Q., Zhou, X.X.: Representative elementary volume analysis of E-B constitutive model parameters of rockfill materials using DEM. Powder Technol 406, 117569 (2022). https://doi.org/10.1016/j.powtec.2022.117569

McDowell, G.R., Bolton, M.D.: On the micromechanics of crushable aggregates. Géotechnique 48, 667–679 (1998). https://doi.org/10.1680/geot.1998.48.5.667

Lim, W.L., McDowell, G.R., Collop, A.C.: The application of Weibull statistics to the strength of railway ballast. Granular Matter 6, 229–237 (2004). https://doi.org/10.1007/s10035-004-0180-z

Liu, B.C., Zhang, J.S., Du, Q.Z.: A study of size effect for compression strength of rock. Chin J Rock Mech Eng 17(6), 611–614 (1998)

Itasca Consulting Group Inc., Particle Flow Code (PFC), Version 5.0, 2014. Minneapolis, Itasca. Available from https://www.itascacg.com/software-faq

Fu, R., Hu, X., Zhou, B.: Discrete element modeling of crushable sands considering realistic particle shape effect. Comput. Geotech. 91, 179–191 (2017). https://doi.org/10.1016/j.compgeo.2017.07.016

Potyondy, D.O.: The bonded-particle model as a tool for rock mechanics research and application: current trends and future directions. Geosyst Eng 18, 1–28 (2015). https://doi.org/10.1080/12269328.2014.998346

Fang, C., Nie, Z., Gong, J., Li, B., Hu, W., Mohammed, A.: Discrete element simulation of effects of multicontact loading on single particle crushing. Particuology 69, 49–60 (2022). https://doi.org/10.1016/j.partic.2021.11.012

Zhou, H.J., Ma, G., Yuan, W., Zhou, W., Chang, X.L.: Size effect on the crushing strengths of rock particles. Rock Soil Mech 38(8), 2425–2433 (2017). https://doi.org/10.16285/j.rsm.2017.08.032

Li, Y., She, C.X.: Numerical simulation of effect of size on crushing strength of rockfill grains using particle flow code. Rock Soil Mech 39(8), 2951–2976 (2018). https://doi.org/10.16285/j.rsm.2016.2525

Wang, J.F., Yan, H.B.: On the role of particle breakage in the shear failure behavior of granular soils by DEM. Int. J. Numer. Anal. Meth. Geomech. 37, 832–854 (2013). https://doi.org/10.1002/nag.1124

Qian, J.G., Gu, J.B., Gu, X.Q., Huang, M.S.: Discrete numerical modeling of granular materials considering crushability. J. Mt. Sci. 14, 758–770 (2017). https://doi.org/10.1007/s11629-016-4051-y

Wu, M.M., Wang, J.F.: A DEM investigation on crushing of sand particles containing intrinsic flaws. Soils Found. 60, 562–572 (2020). https://doi.org/10.1016/j.sandf.2020.03.007

Lim, W.L., McDowell, G.R.: The importance of coordination number in using agglomerates to simulate crushable particles in the discrete element method. Géotechnique 57, 701–705 (2007). https://doi.org/10.1680/geot.2007.57.8.701

Bažant, Z.P., Oh, B.H.: Crack band theory for fracture of concrete. Matériaux et Construction 16, 155–177 (1983). https://doi.org/10.1007/BF02486267

Sun, Z.Z., Ma, G., Zhou, W., Wang, Y.H., Cheng, Y., **ao, H.B.: Influence of particle shape on size effect of crushing strength of rockfill particles. Rock Soil Mech 42(2), 430–438 (2021). https://doi.org/10.16285/j.rsm.2020.0943

Meng, M.Q., Wang, L., Jiang, X., Wang, C.G., Liu, H.L., **ao, Y.: Single-particle crushing test and numerical simulation of coarse grained soil based on size effect. Rock Soil Mech 41(9), 2953–3296 (2020). https://doi.org/10.16285/j.rsm.2019.2000

Wang, W., Coop, M.R.: An investigation of breakage behaviour of single sand particles using a high-speed microscope camera. Géotechnique 66(12), 984–998 (2016). https://doi.org/10.1680/jgeot.15.P.247

Ma, G., Zhou, W., Regueiro, R.A., Wang, Q., Chang, X.L.: Modeling the fragmentation of rock grains using computed tomography and combined fdem. Powder Technol 308, 388–397 (2017). https://doi.org/10.1016/j.powtec.2016.11.046

Yang, J., Luo, X.D.: Exploring the relationship between critical state and particle shape for granular materials. J. Mech. Phys. Solids 84, 196–213 (2015). https://doi.org/10.1016/j.jmps.2015.08.001

**ao, Y., Sun, Y., Zhou, W., Shi, J., Desai, C.S.: Evolution of particle shape produced by sand breakage. Int. J. Geomech. 22, 04022003 (2022). https://doi.org/10.1061/(ASCE)GM.1943-5622.0002333

Acknowledgements

This research was supported by National Key Research and Development Plan of China (Grant No. 2016YFB0201001) and National Natural Science Foundation of China (Grant No. 52209168). These supports are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, J., Chi, S., Zhou, X. et al. Experimental and numerical investigation of the size effect of rockfill particles on crushing strength. Granular Matter 25, 60 (2023). https://doi.org/10.1007/s10035-023-01346-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10035-023-01346-7