Abstract

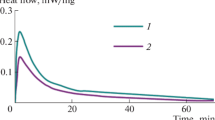

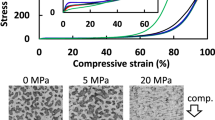

Epoxy porous monoliths were prepared from a commercial epoxy resin, D.E.R. 331, that cured with a tertiary amine, 2,4,6-tris-(dimethylaminomethyl) phenol, in the presence of a solvent, diisobutyl ketone (DIBK). During the curing process, polymers were formed and a decrease in its solubility in DIBK; the solution thus phase-separated, usually referred to as chemically induced phase separation. The phase separation formed interconnected polymer-poor phase that then became interconnected pores after the removal of DIBK. By varying the content of DIBK from 32 to 40 vol.%, epoxy monoliths with interconnected pores were prepared, with surface pore size ranging from 0.20 to 2.33 μm, overall porosity from 0.41 to 0.60, and ethanol permeability from 10 to 4,717 L/(m2 h−1 bar−1). The glass transition temperatures of the epoxy monoliths, measured with differential scanning calorimetry, were all higher than 100 °C, and temperatures of 5 % weight loss, analyzed by thermal gravimetry, were higher than 350 °C, evidencing the monoliths’ high thermal stability. Also, the monolith morphology was found to be strongly related to the reaction mechanism of polymerization. The results indicate that the mechanism of chain initiation and propagation associated with the tertiary amine can effectively form monoliths with interconnected pores, which cannot be easily prepared with a stepwise polymerization mechanism associated with using primary amine as the curing agent.

Similar content being viewed by others

References

Sotiropoulou S, Vamvakaki V, Chaniotakis NA (2005) Biosens Bioelectron 20(8 SPEC. ISS):1674

Huck CW, Bonn GK (2005) Chem Eng Technol 28(12):1457

Barbetta A, Carnachan RJ, Smith KH, Zhao CT, Cameron NR, Kataky R, Hayman M, Przyborski SA, Swan M (2005) Macromol Symp 226(1):203

Higuchi A, Shindo Y, Gomei Y, Mori T, Uyama T, Umezawa A (2005) J Biomed Mater Res B Appl Biomater 74(1):511

Safinia L, Mantalaris A, Bismarck A (2006) Langmuir 22(7):3235

Romeo HE, Vílchez A, Esquena J, Hoppe CE, Williams RJJ (2012) Eur Polym J 48(6):1101

Svec F, Kurganov AA (2008) J Chromatogr A 1184(1–2):281

Varilova T, Madera M, Pacakova V, Stulik K (2006) Curr Proteomics 3(1):55

Zilberman M (2005) Acta Biomater 1(6):615

**e S, Svec F, Fréchet JMJ (1998) Chem Mater 10(12):4072

Svec F, Fréchet JMJ (1999) Ind Eng Chem Res 38(1):34

Peters EC, Svec F, Fréchet JMJ, Viklund C, Irgum K (1999) Macromolecules 32(19):6377

Kiefer J, Hedrick JL, Hilborn JG (1999) Macroporous thermosets by chemically induced phase separation. Adv Polym Sci 147:161–247

Kiefer J, Hilborn JG, Hedrick JL, Cha HJ, Yoon DY, Hedrick JC (1996) Macromolecules 29(26):8546

Della Martina A, Hilborn JG, Mühlebach A (2000) Macromolecules 33(8):2916

Garcia Loera A, Dumon M, Pascault JP (2000) Macromol Symp 151:341

Ai H, Xu K, Chen W, Liu H, Chen M (2009) Polym Int 58(1):105

Luo YS, Cheng KC, Huang ND, Chiang WP, Li SF (2011) J Polym Sci B Polym Phys 49(14):1022

Kiefer J, Hilborn JG, Hedrick JL (1996) Polymer 37(25):5715

Kiefer J, Hilborn JG, Månson JAE, Leterrier Y, Hedrick JL (1996) Macromolecules 29(11):4158

Loera AG, Cara F, Dumon M, Pascault JP (2002) Macromolecules 35(16):6291

Williams RJJ, Rozenberg BA, Pascault JP (1997) Adv Polym Sci 128:95

Tsujioka N, Ishizuka N, Tanaka N, Kubo T, Hosoya K (2008) J Polym Sci A Polym Chem 46(10):3272

Han JL, Hsieh KH, Chiu WY (1993) J Appl Polym Sci 50(6):1099

Dzhavadyan EA, Bogdanova LM, Irzhak VI, Rozenberg BA (1997) Polym Sci Ser A 39(4):383

Dell’Erba IE, Williams RJJ (2006) Polym Eng Sci 46(3):351

Kuzub LI, Irzhak VI (2001) Colloid J 63(1):86

Chakrabarty B, Ghoshal AK, Purkait MK (2008) J Colloid Interface Sci 320(1):245

Chen JL, Chang FC (2001) Polymer 42(5):2193

Vazquez A, Bentaleb D, Williams RJJ (1991) J Appl Polym Sci 43(5):967

Rozenberg B (1986) Kinetics, thermodynamics and mechanism of reactions of epoxy oligomers with amines. Adv Polym Sci 75:113–165

Shechter L, Wynstra J, Kurkjy RP (1956) Ind Eng Chem 48(1):94

Cheng KC, Don TM, Rwei SP, Li YC, Duann YF (2002) J Polym Sci B Polym Phys 40(17):1857

Winter HH, Chambon F (1986) J Rheol 30(2):367

Acknowledgment

We thank the National Science Council of Taiwan for the financial support of this study under Contract NSC 97-2221-E-027-013-MY2.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(PDF 517 kb)

Rights and permissions

About this article

Cite this article

Luo, YS., Cheng, KC., Wu, CL. et al. Preparation of epoxy monoliths via chemically induced phase separation. Colloid Polym Sci 291, 1903–1912 (2013). https://doi.org/10.1007/s00396-013-2926-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00396-013-2926-9