Abstract

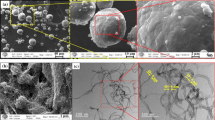

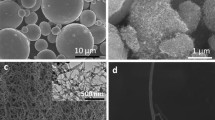

In this study, wet ball milling and hot press methods were used to prepare nanocomposite from ultra-high molecular weight polyethylene (UHMWPE) as a matrix, and modified multi wall carbon nanotubes (MWCNTs) as reinforcement nano-additives. Two batches of MWCNTs were used (Pristine-MWCNTs-B1, and Pristine-MWCNTs-B2). First, the MWCNTs were oxidized (oxide-MWCNTs) by wet chemistry using strong acids, then further functionalized with an amide group (A-MWCNTs). Fourier-transform infrared spectroscopy (FTIR), and Thermal gravimetric analysis (TGA) results confirm the functionalization of the MWCNT with the amide group. Scanning electron microscopy (SEM) and X-ray diffraction (XRD) were used to examine the surface morphology and crystalline behavior of MWCNT after functionalization. Ball milling was used to mix the UHMWPE with pristine MWCNT (1.5% wt), Oxide-MWCNT (1.5% wt), and A-MWCNTs (0.5–2% wt). Then, hot press melting was used to prepare the nanocomposite sheets. Fourier transform infrared spectroscopy (FTIR) confirmed the impact of the balls milling process with time factor on UHMWPE crystallinity and the interaction of the functionalization MWCNT with the UHMWPE matrix. The structure (crystallinity, crystal size) was validated using X-ray diffraction (XRD) patterns. Thermal gravimetric analysis (TGA), differential scanning calorimeter (DSC), and universal testing machine (UTM) were utilized to analyze the structural, thermal, and mechanical properties of the nanocomposites, respectively. The results showed that UHMWPE crystallinity increased after 2 h of ball milling, while crystallinity decreased when pristine-MWCNT, oxide-MWCNTs, and A-MWCNTs (0.5–2 wt%) were added without affecting the crystal structure of UHMWPE. The results showed that adding 1.5 wt% A-MWCNTs-(B1, B2)/UHMWPE increased thermal stability by 16 °C and elongation at the break by up to 74% when used 1.5 wt% A-MWCNT-B1 and 2 wt% A-MWCNT-B2. This shows that the ball milling methods and amide group improved the dispersion and interface interaction between MWCNTs and UHMWPE matrix.

Similar content being viewed by others

Data availability

All data generated or analyzed during this study are included in this published article. No supplementary materials.

References

Iijima S (1991) Helical microtubules of graphitic carbon. Nature 354(6348):56–58. https://doi.org/10.1038/354056a0

Munkhbayar B, Nine MJ, Hwang S, Kim J, Bae K, Chung H, Jeong H (2012) Effect of grinding speed changes on dispersibility of the treated multi-walled carbon nanotubes in aqueous solution and its thermal characteristics. Chem Eng Process 61:36–41. https://doi.org/10.1016/j.cep.2012.06.013

Wu CS, Liao HT (2007) Study on the preparation and characterization of biodegradable polylactide/multi-walled carbon nanotubes nanocomposites. Polymer 48(15):4449–4458. https://doi.org/10.1016/j.polymer.2007.06.004

Fonseca A, Kanagaraj S, Oliveira MS, Simões JA (2011) Enhanced UHMWPE reinforced with MWCNT through mechanical ball-milling. In: Defect and diffusion forum, vol 312. Trans Tech Publications Ltd. p 1238–1243. https://doi.org/10.4028/www.scientific.net/DDF.312-315.1238

Munkhbayar B, Nine MJ, Jeoun J, Bat-Erdene M, Chung H, Jeong H (2013) Influence of dry and wet ball milling on dispersion characteristics of the multi-walled carbon nanotubes in aqueous solution with and without surfactant. Powder Technol 234:132–140. https://doi.org/10.1016/j.powtec.2012.09.045

Li Y, Huang X, Zeng L, Li R, Tian H, Fu X, Zhong WH (2019) A review of the electrical and mechanical properties of carbon nanofiller-reinforced polymer composites. J Mater Sci 54(2):1036–1076. https://doi.org/10.1007/s10853-018-3006-9

Mohd Nurazzi N, Asyraf MM, Khalina A, Abdullah N, Sabaruddin FA, Kamarudin SH, Sapuan SM (2021) Fabrication, functionalization, and application of carbon nanotube-reinforced polymer composite: an overview. Polymers 13(7):1047. https://doi.org/10.3390/polym13071047

Bozeya A, Makableh YF, Abu-Zurayk R, Khalaf A, Al Bawab A (2021) Thermal and structural properties of high density polyethylene/carbon nanotube nanocomposites: a comparison study. Chemosensors 9(6):136. https://doi.org/10.3390/chemosensors9060136

Rennhofer H, Zanghellini B (2021) Dispersion state and damage of carbon nanotubes and carbon nanofibers by ultrasonic dispersion: a review. Nanomaterials 11(6):1469. https://doi.org/10.3390/nano11061469

Dabees S, Tirth V, Mohamed A, Kamel BM (2021) Wear performance and mechanical properties of MWCNT/HDPE nanocomposites for gearing applications. J Market Res 12:2476–2488. https://doi.org/10.1016/j.jmrt.2020.09.129

Mallakpour S, Zadehnazari A (2014) Effect of amino acid-functionalized multi-walled carbon nanotubes on the properties of dopamine-based poly (amide-imide) composites: an experimental study. Bull Mater Sci 37(5):1065–1077. https://doi.org/10.1007/s12034-014-0046-x

Spitalsky Z, Tasis D, Papagelis K, Galiotis C (2010) Carbon nanotube–polymer composites: chemistry, processing, mechanical and electrical properties. Prog Polym Sci 35(3):357–401. https://doi.org/10.1016/j.progpolymsci.2009.09.003

Long M, Rack HJ (1998) Titanium alloys in total joint replacement—a materials science perspective. Biomaterials 19(18):1621–1639. https://doi.org/10.1016/S0142-9612(97)00146-4

Afshari M, Sikkema DJ, Lee K, Bogle M (2008) High performance fibers based on rigid and flexible polymers. Polym Rev 48(2):230–274. https://doi.org/10.1080/15583720802020129

Patil NA, Njuguna J, Kandasubramanian B (2020) UHMWPE for biomedical applications: performance and functionalization. Eur Polym J 125:109529. https://doi.org/10.1016/j.eurpolymj.2020.109529

Fonseca A et al (2011) Enhanced UHMWPE reinforced with MWCNT through mechanical ball-milling. Defect and diffusion forum, vol 312. Trans Tech Publications Ltd. https://doi.org/10.4028/www.scientific.net/DDF.312-315.1238

Campo N, Visco AM (2010) Incorporation of carbon nanotubes into ultra high molecular weight polyethylene by high energy ball milling. Int J Polymer Anal Charact 15(7):438–449. https://doi.org/10.1080/1023666X.2010.510110

Enqvist E et al (2014) The effect of ball milling time and rotational speed on ultra high molecular weight polyethylene reinforced with multiwalled carbon nanotubes. Polym Compos 37(4):1128–1136. https://doi.org/10.1002/pc.23275

Yahia M et al (2022) Investigation of the mechanical and thermal stability of ultra-high molecular weight polyethylene by using amide-multi-walled carbon nanotubes as a reinforcement material. Adv Nat Sci Nanosci Nanotechnol 13(1):015011. https://doi.org/10.1088/2043-6262/ac5d59

Ingham B, Toney MF (2014) X-ray diffraction for characterizing metallic films. In: Metallic films for electronic, optical and magnetic applications. Woodhead Publishing, p 3–38. https://doi.org/10.1533/9780857096296.1.3

Menczel JD, Bruce Prime R (eds) (2009) Thermal analysis of polymers: fundamentals and applications. John Wiley & Sons. https://doi.org/10.1002/9780470423837

Kanai Y et al (2010) Atomistic oxidation mechanism of a carbon nanotube in nitric acid. Phys Rev Lett 104(6):066401. https://doi.org/10.1103/PhysRevLett.104.066401

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The Authors declare that they have no conflict of interest.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Ethical approval

Not applicable.

Informed consent

The Publication is approved by all authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Bozeya, A., Makableh, Y.F., Al-Mezead, L.A. et al. Wet ball milling and hot press for the preparation of UHMWPE/modified MWCNTs nanocomposite with enhanced mechanical and thermal properties. Polym. Bull. 81, 1707–1727 (2024). https://doi.org/10.1007/s00289-023-04790-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-023-04790-w