Abstract

The demand for 1,3-propanediol (1,3-PDO) has increased sharply due to its role as a monomer for the synthesis of polytrimethylene terephthalate (PTT). Although Clostridium butyricum is considered to be one of the most promising bioproducers for 1,3-PDO, its low productivity hinders its application on industrial scale because of the longer time needed for anaerobic cultivation. In this study, an excellent C. butyricum (DL07) strain was obtained with high-level titer and productivity of 1,3-PDO, i.e., 104.8 g/L and 3.38 g/(L•h) vs. 94.2 g/L and 3.04 g/(L•h) using pure or crude glycerol as substrate in fed-batch fermentation, respectively. Furthermore, a novel sequential fed-batch fermentation was investigated, in which the next bioreactor was inoculated by C. butyricum DL07 cells growing at exponential phase in the prior bioreactor. It could run steadily for at least eight cycles. The average concentration of 1,3-PDO in eight cycles was 85 g/L with the average productivity of 3.1 g/(L•h). The sequential fed-batch fermentation could achieve semi-continuous production of 1,3-PDO with higher productivity than repeated fed-batch fermentation and would greatly contribute to the industrial production of 1,3-PDO by C. butyricum.

Key points

• A novel C. butyricum strain was screened to produce 104.8 g/L 1,3-PDO from glycerol.

• Corn steep liquor powder was used as a cheap nitrogen source for 1,3-PDO production.

• A sequential fed-batch fermentation process was established for 1,3-PDO production.

• An automatic glycerol feeding strategy was applied in the production of 1,3-PDO.

Similar content being viewed by others

References

Anitha M, Kamarudin SK, Kofli NT (2016) The potential of glycerol as a value-added commodity. Chem Eng J 295:119–130. https://doi.org/10.1016/j.cej.2016.03.012

Cassir N, Benamar S, La Scola B (2016) Clostridium butyricum: from beneficial to a new emerging pathogen. Clin Microbiol Infect 22(1):37–45. https://doi.org/10.1016/j.cmi.2015.10.014

Chatzifragkou PS (2012) Effect of impurities in biodiesel-derived waste glycerol on the performance and feasibility of biotechnological processes. Appl Microbiol Biotechnol 95(1):13–27. https://doi.org/10.1007/s00253-012-4111-3

Chatzifragkou A, Dietz D, Komaitis M, Zeng AP, Papanikolaou S (2010) Effect of biodiesel-derived waste glycerol impurities on biomass and 1,3-propanediol production of Clostridium butyricum VPI 1718. Biotechnol Bioeng 107(1):76–84. https://doi.org/10.1007/s00253-012-4111-3

Chatzifragkou A, Papanikolaou S, Dietz D, Doulgeraki AI, Nychas GE, Zeng AP (2011) Production of 1,3-propanediol by Clostridium butyricum growing on biodiesel-derived crude glycerol through a non-sterilized fermentation process. Appl Microbiol Biotechnol 91(1):101–112. https://doi.org/10.1007/s00253-011-3247-x

Chatzifragkou A, Papanikolaou S, Kopsahelis N, Kachrimanidou V, Dorado MP, Koutinas AA (2014) Biorefinery development through utilization of biodiesel industry by-products as sole fermentation feedstock for 1,3-propanediol production. Bioresour Technol 159:167–175. https://doi.org/10.1016/j.biortech.2014.02.021

Chen X, Zhang DJ, Qi WT, Gao SJ, **u ZL, Xu P (2003) Microbial fed-batch production of 1,3-propanediol by Klebsiella pneumoniae under micro-aerobic conditions. Appl Microbiol Biotechnol 63(2):143–146. https://doi.org/10.1007/s00253-003-1369-5

Colin T, Bories A, Moulin G (2000) Inhibition of Clostridium butyricum by 1,3-propanediol and diols during glycerol fermentation. Appl Microbiol Biotechnol 54(2):201–205. https://doi.org/10.1007/s002530000365

Guo Y, Dai L, **n B, Tao F, Tang H, Shen Y, Xu P (2017) 1,3-Propanediol production by a newly isolated strain, Clostridium perfringens GYL. Bioresour Technol 233:406–412. https://doi.org/10.1016/j.biortech.2017.02.116

Hakalehto E, Hänninen O (2012) Gaseous CO2 signal initiates growth of butyric-acid-producing Clostridium butyricum in both pure culture and mixed cultures with Lactobacillus brevis. Can J Microbiol 58(7):928–931. https://doi.org/10.1139/w2012-059

Hiremath A, Kannabiran M, Rangaswamy V (2011) 1,3-Propanediol production from crude glycerol from jatropha biodiesel process. New Biotechnol 28(1):19–23. https://doi.org/10.1016/j.nbt.2010.06.006

Hirschmann S, Baganz K, Koschik I, Vorlop KD (2005) Development of an integrated bioconversion process for the production of 1,3-propanediol from raw glycerol waters. Landbauforschung Völkenrode 55(4):261–267. https://doi.org/10.1300/J064v25n03_09

Huang J, Chen Z, Sun Y, Liu D (2015) Automatically feeding strategy for 1, 3-propanediol fermentation of Klebsiella pneumoniae LDH526. Chin J Biotechnol 31(10):1520–1527

Ji XJ, Huang H, Zhu JG, Hu N, Li S (2009) Efficient 1,3-propanediol production by fed-batch culture of Klebsiella Pneumoniae: the role of pH fluctuation. Appl Biochem Biotechnol 159(3):605–613. https://doi.org/10.1007/s12010-008-8492-9

Jiang W, Wang S, Wang Y, Fang B (2016) Key enzymes catalyzing glycerol to 1,3-propanediol. Biotechnol Biofuels 9(1):57. https://doi.org/10.1186/s13068-016-0473-6

Jiang LL, Liu HF, Mu Y, Sun YQ, **u ZL (2017) High tolerance to glycerol and high production of 1,3-propanediol in batch fermentations by microbial consortium from marine sludge. Eng Life Sci 17(6):635–644. https://doi.org/10.1002/elsc.201600215

** P, Lu SG, Huang H, Luo F, Li S (2011) Enhanced reducing equivalent generation for 1,3-propanediol production through cofermentation of glycerol and xylose by Klebsiella pneumoniae. Appl Biochem Biotechnol 165(7):1532–1542. https://doi.org/10.1007/s12010-011-9373-1

Jolly J, Hitzmann B, Ramalingam S, Ramachandran KB (2014) Biosynthesis of 1,3-propanediol from glycerol with Lactobacillus reuteri: effect of operating variables. J Biosci Bioeng 118(2):188–194. https://doi.org/10.1016/j.jbiosc.2014.01.003

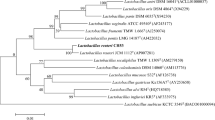

Ju JH, Wang D, Heo SY, Kim MS, Seo JW, Kim YM, Kim DH, Kang SA, Kim CH, Oh BR (2020) Enhancement of 1,3-propanediol production from industrial by-product by Lactobacillus reuteri CH53. Microb Cell Factories 19(1):6. https://doi.org/10.1186/s12934-019-1275-x

Jun SA, Moon C, Kang CH, Kong SW, Sang BI, Um Y (2010) Microbial fed-batch production of 1,3-propanediol using raw glycerol with suspended and immobilized Klebsiella pneumoniae. Appl Biochem Biotechnol 161(1–8):491–501. https://doi.org/10.1007/s12010-009-8839-x

Kaur G, Srivastava AK, Chand S (2012a) Advances in biotechnological production of 1,3-propanediol. Biochem Eng J 64:106–118. https://doi.org/10.1016/j.bej.2012.03.002

Kaur G, Srivastava AK, Chand S (2012b) Simple strategy of repeated batch cultivation for enhanced production of 1,3-propanediol using Clostridium diolis. Appl Biochem Biotechnol 167(5):1061–1068. https://doi.org/10.1007/s12010-012-9715-7

Lee CS, Aroua MK, Daud WMAW, Cognet P, Pérès-Lucchese Y, Fabre PL, Reynes O, Latapie L (2015) A review: conversion of bioglycerol into 1,3-propanediol via biological and chemical method. Renew Sust Energ Rev 42:963–972. https://doi.org/10.1016/j.rser.2014.10.033

Lee JH, Jung MY, Oh MK (2018) High-yield production of 1,3-propanediol from glycerol by metabolically engineered Klebsiella pneumoniae. Biotechnol Biofuels 11(1):104. https://doi.org/10.1186/s13068-018-1100-5

Liu H, Xu Y, Zheng Z, Liu D (2010) 1,3-Propanediol and its copolymers: research, development and industrialization. Biotechnol J 5(11):1137–1148. https://doi.org/10.1002/biot.201000140

Maina S, Kachrimanidou V, Ladakis D, Papanikolaou S, de Castro AM, Koutinas A (2019) Evaluation of 1,3-propanediol production by two Citrobacter freundii strains using crude glycerol and soybean cake hydrolysate. Environ Sci Pollut Res 26(35):35523–35532. https://doi.org/10.1007/s11356-019-05485-4

Matsumura M, Nomura N, Sato S (2008) Growth and 1,3-propanediol production on pre-treated sunflower oil bio-diesel raw glycerol using a strict anaerobe-Clostridium butyricum. Curr Res Bacteriol 1(1):7–16. https://doi.org/10.3923/crb.2008.7.16

Metsoviti M, Zeng AP, Koutinas AA, Papanikolaou S (2013) Enhanced 1,3-propanediol production by a newly isolated Citrobacter freundii strain cultivated on biodiesel-derived waste glycerol through sterile and non-sterile bioprocesses. J Biotechnol 163(4):408–418. https://doi.org/10.1016/j.jbiotec.2012.11.018

Mu Y, Teng H, Zhang DJ, Wang W, **u ZL (2006) Microbial production of 1,3-propanediol by Klebsiella pneumoniae using crude glycerol from biodiesel preparations. Biotechnol Lett 28(21):1755–1759. https://doi.org/10.1007/s10529-006-9154-z

Oh BR, Lee SM, Heo SY, Seo JW, Kim CH (2018) Efficient production of 1,3-propanediol from crude glycerol by repeated fed-batch fermentation strategy of a lactate and 2,3-butanediol deficient mutant of Klebsiella pneumoniae. Microb Cell Factories 17(1):92. https://doi.org/10.1186/s12934-018-0921-z

Parate R, Mane R, Dharne M, Rode C (2018) Mixed bacterial culture mediated direct conversion of bio-glycerol to diols. Bioresour Technol 250:86–93. https://doi.org/10.1016/j.biortech.2017.11.019

Pflügl S, Marx H, Mattanovich D, Sauer M (2014) Heading for an economic industrial upgrading of crude glycerol from biodiesel production to 1,3-propanediol by Lactobacillus diolivorans. Bioresour Technol 152:499–504. https://doi.org/10.1016/j.biortech.2013.11.041

Rahim SANM, Lee CS, Abnisa F, Aroua MK, Daud WAW, Cognet P, Pérès Y (2020) A review of recent developments on kinetics parameters for glycerol electrochemical conversion – a by-product of biodiesel. Sci Total Environ 705:135137. https://doi.org/10.1016/j.scitotenv.2019.135137

Reimann A, Biebl H (1996) Production of 1,3-propanediol by Clostridium butyricum DSM 5431 and product tolerant mutants in fedbatch culture: feeding strategy for glycerol and ammonium. Biotechnol Lett 18(7):827–832. https://doi.org/10.1007/BF00127897

Ringel AK, Wilkens E, Hortig D, Willke T, Vorlop KD (2012) An improved screening method for microorganisms able to convert crude glycerol to 1,3-propanediol and to tolerate high product concentrations. Appl Biochem Biotechnol 93(3):1049–1056. https://doi.org/10.1007/s00253-011-3594-7

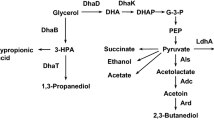

Saint-Amans S, Girbal L, Andrade J, Ahrens K, Soucaille P (2001) Regulation of carbon and electron flow in Clostridium butyricum VPI 3266 grown on glucose-glycerol mixtures. J Bacteriol 183(5):1748–1754. https://doi.org/10.1128/JB.183.5.1748-1754.2001

Saxena RK, Anand P, Saran S, Isar J (2009) Microbial production of 1,3-propanediol: recent developments and emerging opportunities. Biotechnol Adv 27(6):895–913. https://doi.org/10.1016/j.biotechadv.2009.07.003

Sharma P, Melkania U (2018) Enhancement effect of amino acids on hydrogen production from organic fraction of municipal solid waste using co-culture of Escherichia coli and Enterobacter aerogenes. Energ Convers Manage 163:260–267. https://doi.org/10.1016/j.enconman.2018.02.072

Song ZY, Teng H, **u ZL (2012) Coupled-feeding strategy based on the cell growth and metabolism during 1,3-propanediol fermentation. Chin J Process Eng 12(6):996–1001

Sun YQ, Shen JT, Yan L, Zhou JJ, Jiang LL, Chen Y, Yuan JL, Feng EM, **u ZL (2018) Advances in bioconversion of glycerol to 1,3-propanediol: prospects and challenges. Process Biochem 71:134–146. https://doi.org/10.1016/j.procbio.2018.05.009

Szymanowska-Powalowska D (2014) 1,3-Propanediol production from crude glycerol by Clostridium butyricum DSP1 in repeated batch. Electron J Biotechnol 17(6):322–328. https://doi.org/10.1016/j.ejbt.2014.10.00

Tee ZK, Jahim JM, Tan JP, Kim BH (2017) Preeminent productivity of 1,3-propanediol by Clostridium butyricum JKT37 and the role of using calcium carbonate as pH neutraliser in glycerol fermentation. Bioresour Technol 233:296–304. https://doi.org/10.1016/j.biortech.2017.02.110

Vivek N, Pandey A, Binod P (2017) 31-Production and applications of 1,3-propanediol. In: Current developments in biotechnology and bioengineering, p 719–738. https://doi.org/10.1016/B978-0-444-63662-1.00031-2.

Wang JF, **u ZL, Fan SD (2001) Determination of glycerin concentration during the fermentation of glycerin to 1, 3-propanediol. Ind Microbiol 31:33–35

Wang XL, Zhou JJ, Sun YQ, **u ZL (2019) Bioconversion of raw glycerol from waste cooking-oil-based biodiesel production to 1,3-propanediol and lactate by a microbial consortium. Front Bioeng Biotechnol 7:14. https://doi.org/10.3389/fbioe.2019.00014

Westbrook AW, Miscevic D, Kilpatrick S, Bruder MR, Moo-Young M, Chou CP (2019) Strain engineering for microbial production of value-added chemicals and fuels from glycerol. Biotechnol Adv 37(4):538–568. https://doi.org/10.1016/j.biotechadv.2018.10.006

Wilkens E, Ringel AK, Hortig D, Willke T, Vorlop KD (2012) High-level production of 1,3-propanediol from crude glycerol by Clostridium butyricum AKR102a. Appl Microbiol Biotechnol 93(3):1057–1063. https://doi.org/10.1007/s00253-011-3595-6

Wischral D, Zhang J, Cheng C, Lin M, De Souza LMG, Pessoa FLP, NP Jr, Yang ST (2016) Production of 1,3-propanediol by Clostridium beijerinckii DSM 791 from crude glycerol and corn steep liquor: process optimization and metabolic engineering. Bioresour Technol 212:100–110. https://doi.org/10.1016/j.biortech.2016.04.020

**u ZL, Zeng AP (2008) Present state and perspective of downstream processing of biologically produced 1,3-propanediol and 2,3-butanediol. Appl Microbiol Biotechnol 78(6):917–926. https://doi.org/10.1007/s00253-008-1387-4

**u ZL, Song BH, Wang ZT, Sun LH, Feng EM, Zeng AP (2004) Optimization of dissimilation of glycerol to 1,3-propanediol by Klebsiella pneumoniae in one- and two-stage anaerobic cultures. Biochem Eng J 19(3):189–197. https://doi.org/10.1016/j.bej.2003.12.005

Xue X, Li W, Li Z, **a Y, Ye Q (2010) Enhanced 1,3-propanediol production by supply of organic acids and repeated fed-batch culture. J Ind Microbiol Biotechnol 37(7):681–687. https://doi.org/10.1007/s10295-010-0711-z

Yang F, Hanna MA, Sun R (2012) Value-added uses for crude glycerol--a byproduct of biodiesel production. Biotechnol Biofuels 5(1):13. https://doi.org/10.1186/1754-6834-5-13

Yang X, Kim DS, Choi HS, Kim CK, Thapa LP, Park C, Kim SW (2017) Repeated batch production of 1,3-propanediol from biodiesel derived waste glycerol by Klebsiella pneumoniae. Chem Eng J 314:660–669. https://doi.org/10.1016/j.cej.2016.12.029

Yang X, Choi HS, Lee JH, Lee SK, Han SO, Park C, Kim SW (2018) Improved production of 1,3-propanediol from biodiesel-derived crude glycerol by Klebsiella pneumoniae in fed-batch fermentation. Chem Eng J 349:25–36. https://doi.org/10.1016/j.cej.2018.05.042

Yang M, An Y, Zabed HM, Guo Q, Yun J, Zhang G, Award FN, Sun W, Qi X (2019) Random mutagenesis of Clostridium butyricum strain and optimization of biosynthesis process for enhanced production of 1,3-propanediol. Bioresour Technol 284:188–196. https://doi.org/10.1016/j.biortech.2019.03.098

Zeng AP, Sabra W (2011) Microbial production of diols as platform chemicals: recent progresses. Curr Opin Biotechnol 22(6):749–757. https://doi.org/10.1016/j.copbio.2011.05.005

Zhang AH, Liu HL, Huang SY, Fu YS, Fang BS (2018) Metabolic profiles analysis of 1,3-propanediol production process by Clostridium butyricum through repeated batch fermentation coupled with activated carbon adsorption. Biotechnol Bioeng 115(3):684–693. https://doi.org/10.1002/bit.26488

Zhou JJ, Shen JT, Jiang LL, Sun YQ, Mu Y, **u ZL (2017) Selection and characterization of an anaerobic microbial consortium with high adaptation to crude glycerol for 1,3-propanediol production. Appl Microbiol Biotechnol 101(15):5985–5996. https://doi.org/10.1007/s00253-017-8311-8

Zhou JJ, Shen JT, Wang XL, Sun YQ, **u ZL (2018) Stability and oscillatory behavior of microbial consortium in continuous conversion of crude glycerol to 1,3-propanediol. Appl Microbiol Biotechnol 102(19):8291–8305. https://doi.org/10.1007/s00253-018-9244-6

Funding

This work was supported by the National Natural Science Foundation of China (Grant 521 No. 21476042, awarded to Zhi-Long **u) and the Fundamental Research Funds for the Central Universities 522 (Grant No. DUT17ZD209, awarded to Ya-Qin Sun).

Author information

Authors and Affiliations

Contributions

ZLX and XLW contributed conception and design of the study. XLW, JJZ, JTS, and YFZ performed the experiments. XLW, JJZ, and YQS analyzed the data. XLW wrote the manuscript. All authors contributed to manuscript revision, read, and approved the submitted version.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, XL., Zhou, JJ., Shen, JT. et al. Sequential fed-batch fermentation of 1,3-propanediol from glycerol by Clostridium butyricum DL07. Appl Microbiol Biotechnol 104, 9179–9191 (2020). https://doi.org/10.1007/s00253-020-10931-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-020-10931-2